Hydraulic pendulum force measuring mechanism

A technology of force measurement and hydraulic pressure, which is applied in the direction of measuring devices, measurement of force balance force, instruments, etc., can solve problems such as low precision, changes in indication values, inability to meet high-precision detection requirements, and long-term use. Achieve the effect of improving sliding performance and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

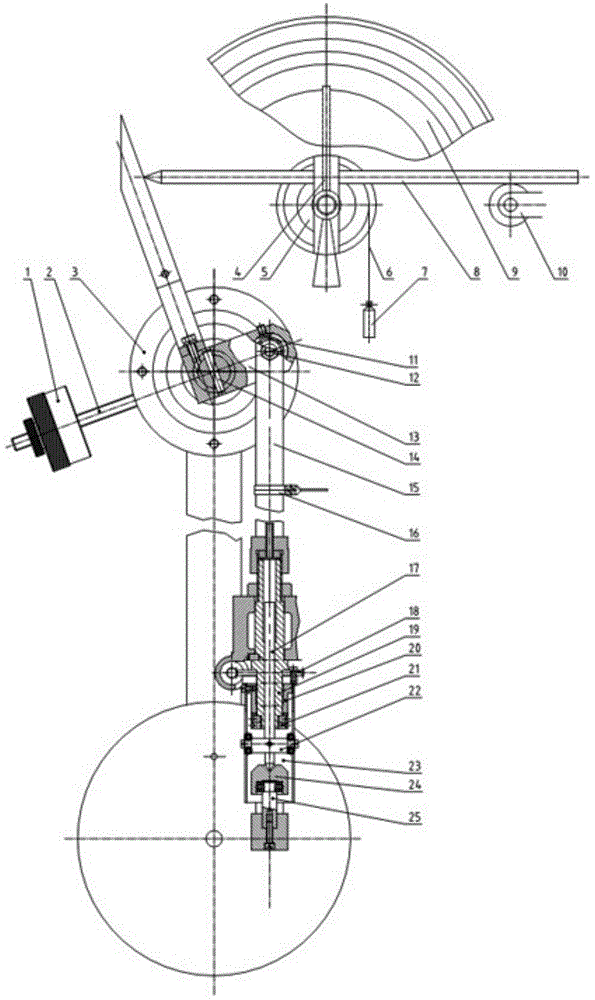

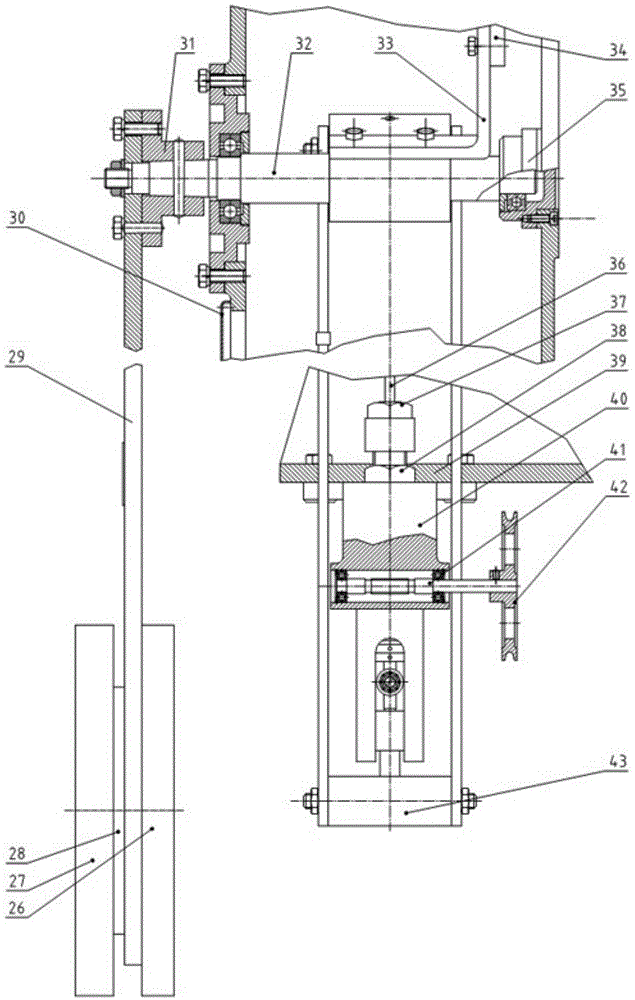

[0017] Such as figure 1 , figure 2 As shown, including balance thallium 1, balance rod 2, rear bearing flange seat 3, pointer 4, worm gear 5, string 6, weight 7, worm 8, dial 9, support wheel 10, bearing 11, connecting rod shaft 12. Swing rod shaft seat 13, conical pin 14, pull plate 15, limit bumper 16, force measuring rod 17, gear 18, force measuring sleeve 19, shaft sleeve 20, joint cap 21, transverse shaft 22, casing 23 , top block 24, bearing shaft 25, first pendulum 26, second pendulum 27, third pendulum 28, pendulum 29, upper box cover 30, pendulum flange seat 31, pendulum shaft 32, bent plate 33. Push plate 34, front bearing flange seat 35, oil pipe 36, first nut 37, second nut 38, upper box body 39, force measuring bush seat 40, screw rod 41, pulley 42, connecting rod shaft seat 43 etc.

[0018] Such as figure 1 , figure 2 As shown, a hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com