High-temperature high-pressure resistant air exhaust sealing gasket of diesel engine and manufacturing method of high-temperature high-pressure resistant air exhaust sealing gasket

An exhaust sealing, high temperature resistant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

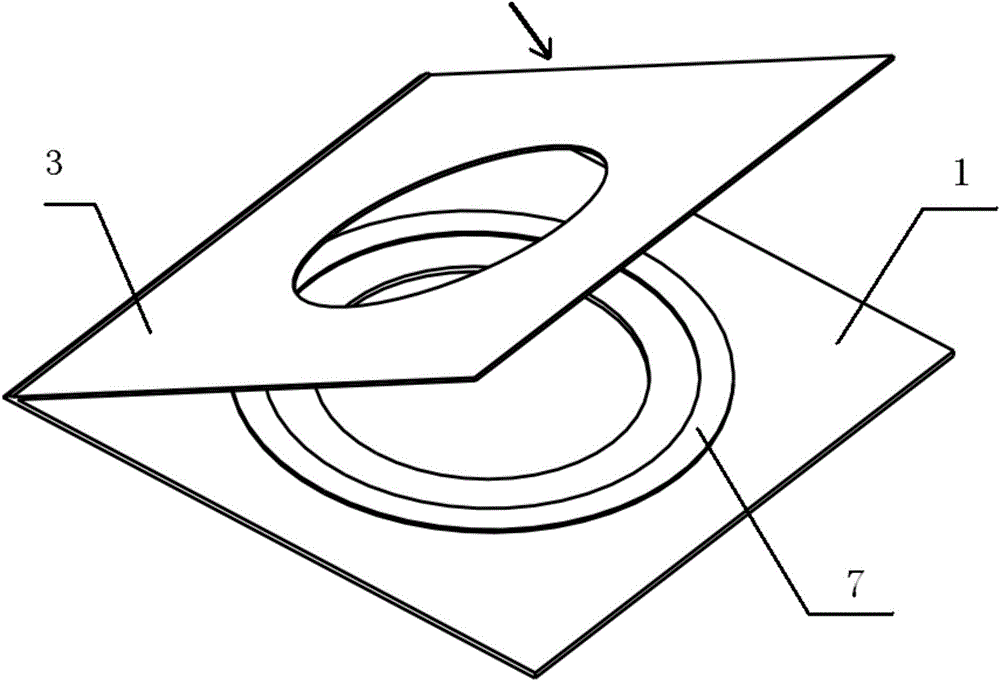

[0030] Attached below figure 1 Specific embodiments of the present invention are described in detail.

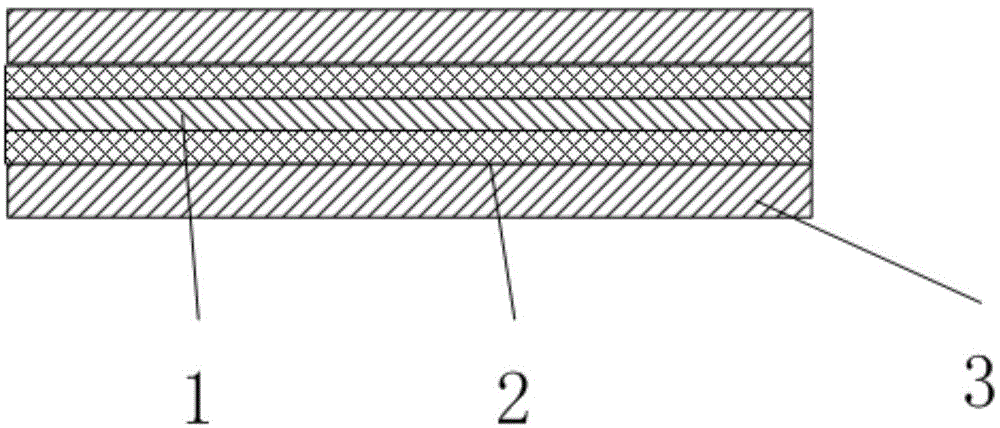

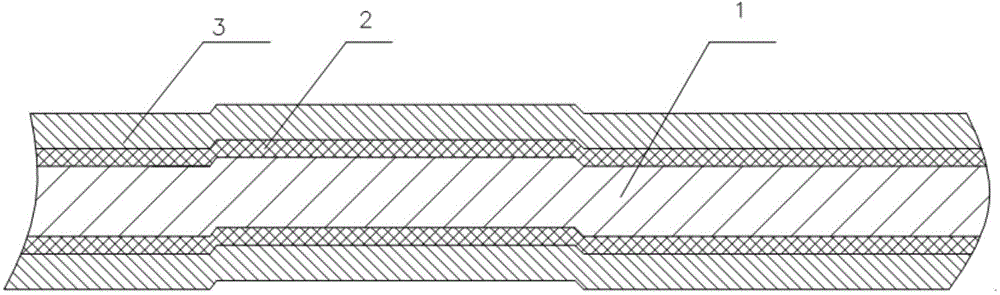

[0031] A high temperature and high pressure exhaust sealing gasket for diesel engines, such as figure 1 As shown, it consists of a high-temperature-resistant steel sheet 1 in the middle layer and flexible graphite sheets 3 on both sides thereof, and the high-temperature-resistant steel sheet 1 and the flexible graphite sheet 3 are bonded together by an adhesive layer 2 . The high-temperature-resistant steel sheet 1 and the flexible graphite sheet 3 of the present invention are formed by pressing and bonding through an adhesive layer 2 .

[0032] The flexible graphite sheet 3 of the present invention is formed by pressing expanded graphite, and the bonding layer 2 can be made of 704 silicone rubber materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com