Four-point bending test clamp

A four-point bending and test fixture technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to perform four-point bending experiments, and achieve the effect of convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

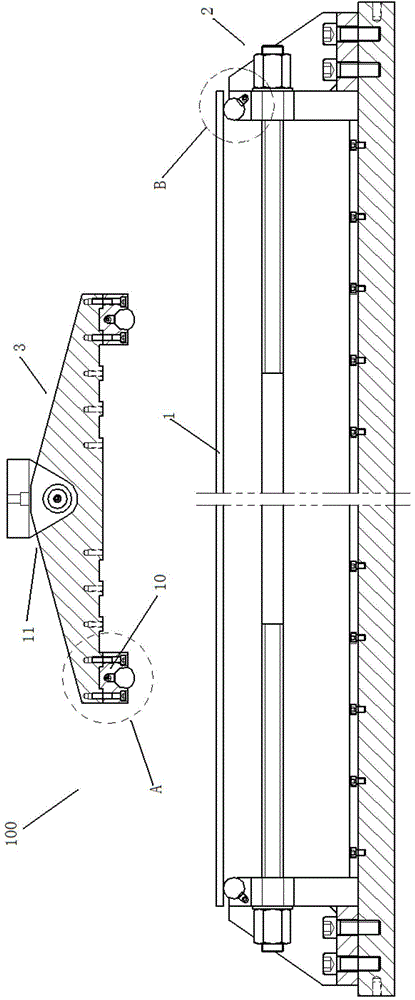

[0022] figure 1 It is a structural schematic diagram of a four-point bending test fixture in an embodiment of the present invention.

[0023] Such as figure 1 As shown, the four-point bending test fixture 100 in this embodiment includes: a supporting part 2 and a loading part 3 .

[0024] The support part 2 is located below the test piece 1 and is used to support the test piece 1 .

[0025] The loading part 2 is located above the test piece 1 and applies a pressure load to the test piece 1 .

[0026] The loading part 3 includes two pressure roller units 10 which are in direct contact with the test piece 1 and a loading body 11 detachably installed on the loading end of the universal testing machine or the press.

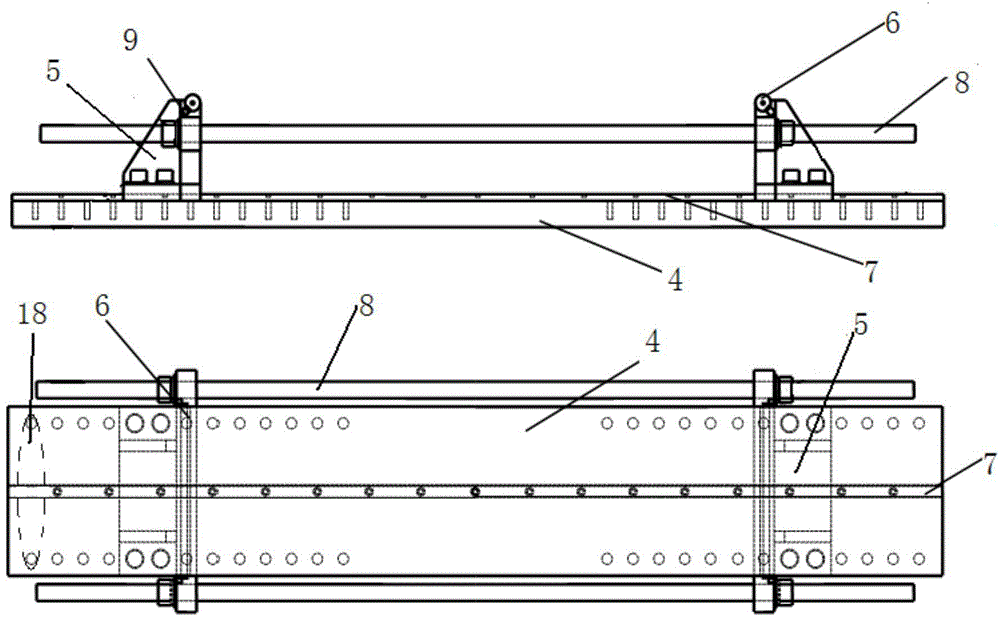

[0027] figure 2 It is a structural schematic diagram of the support part in the four-point bending test fixture.

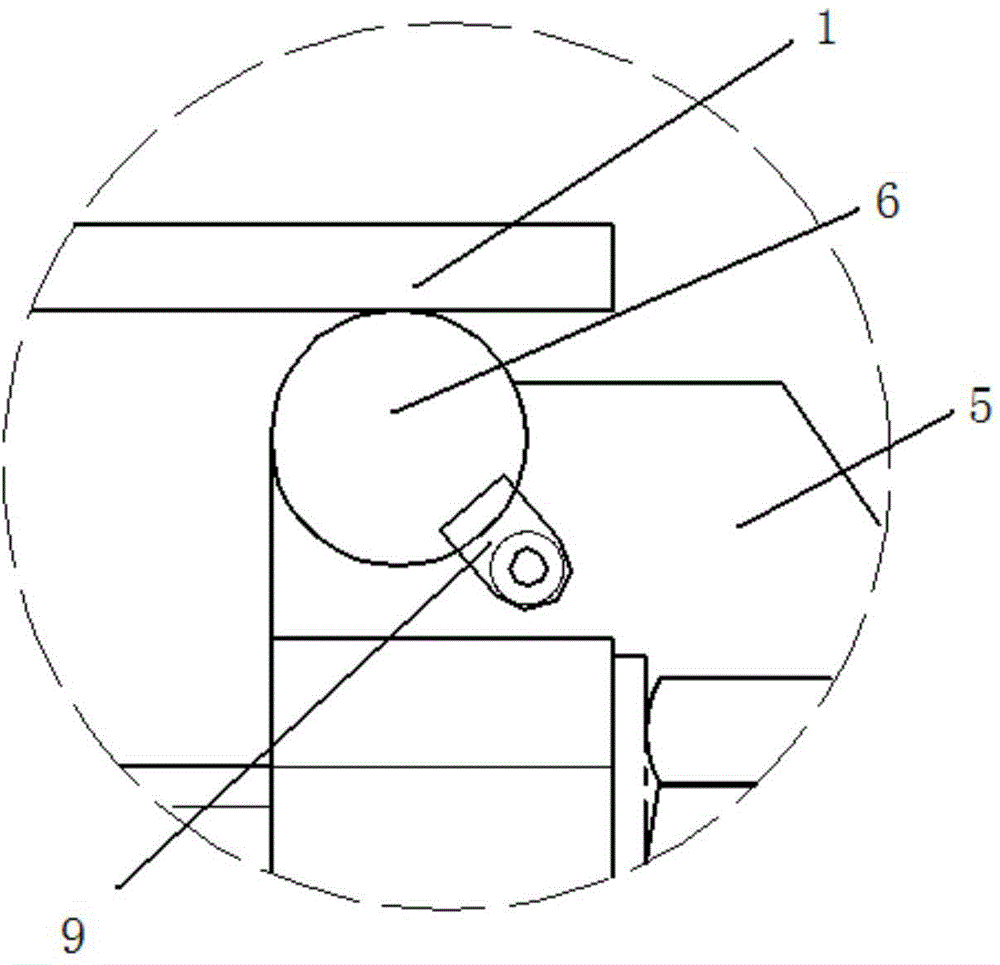

[0028] As shown in Figure 2, the support part 2 includes a bottom plate 4 detachably installed on the workbench, two adjustable supports 5 fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com