Door and window physical performance testing equipment

A technology of physical properties and testing equipment, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve problems such as time-consuming, avoid offset, reduce experimental deviation, and ensure experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be described in further detail below in conjunction with the accompanying drawings.

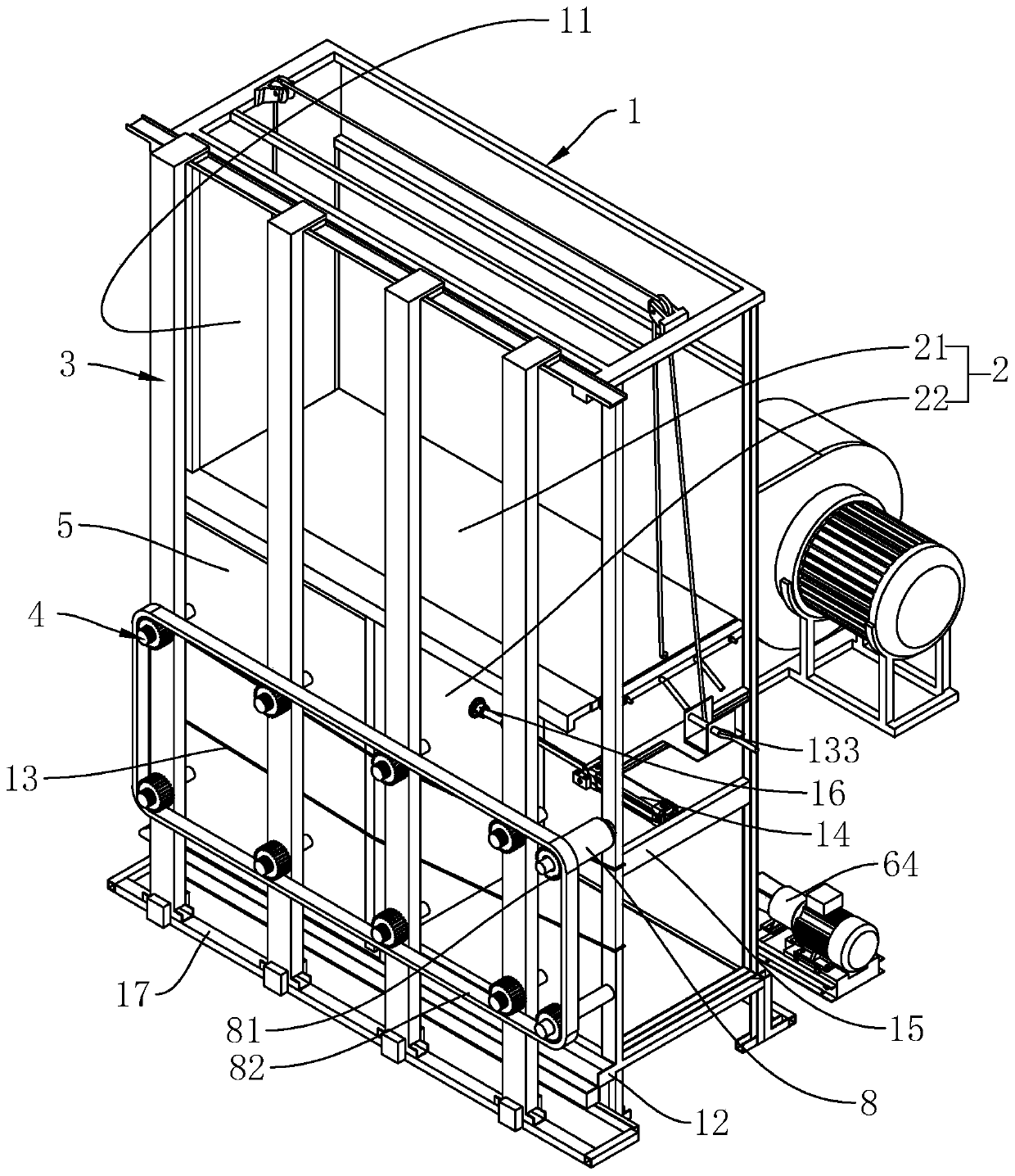

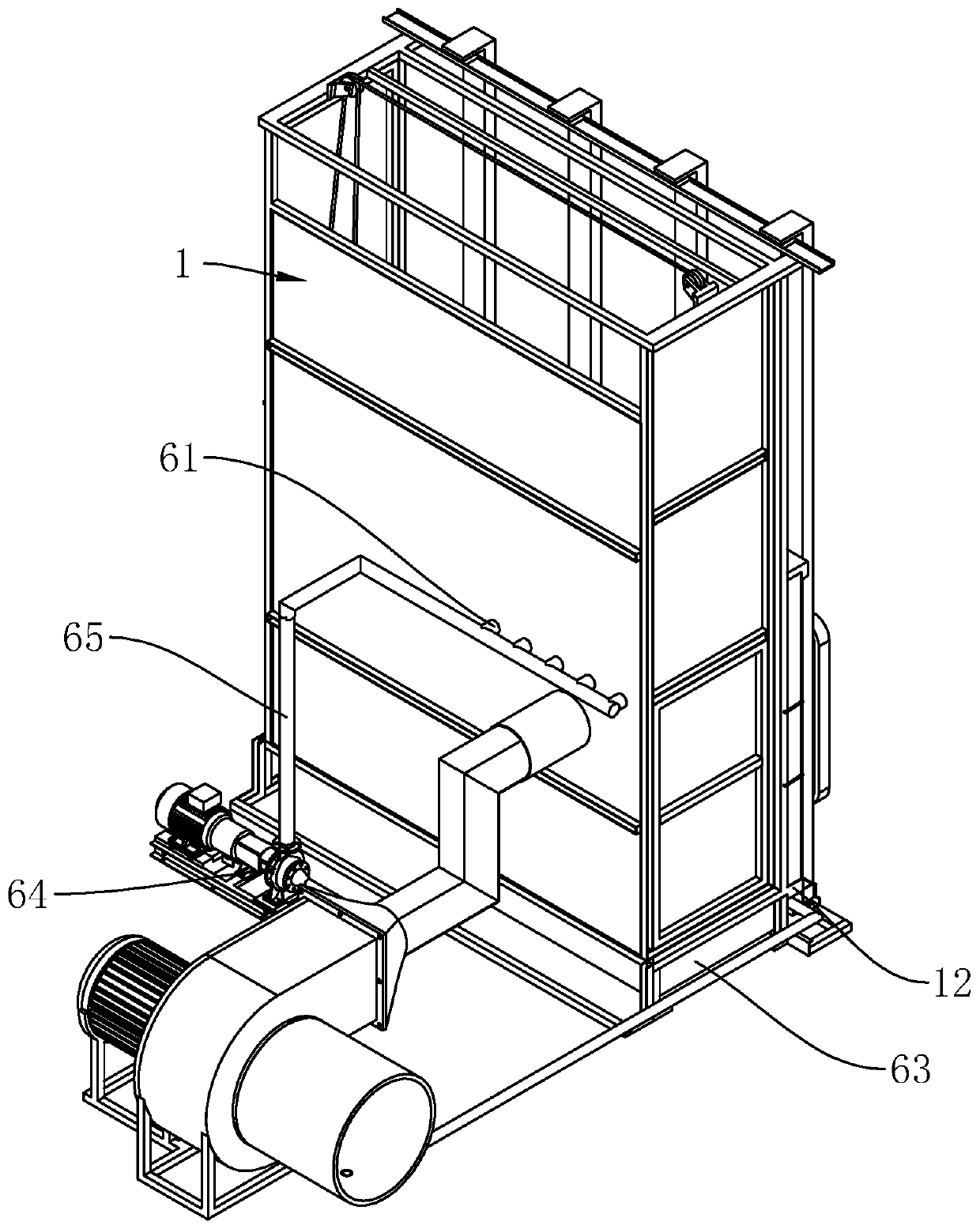

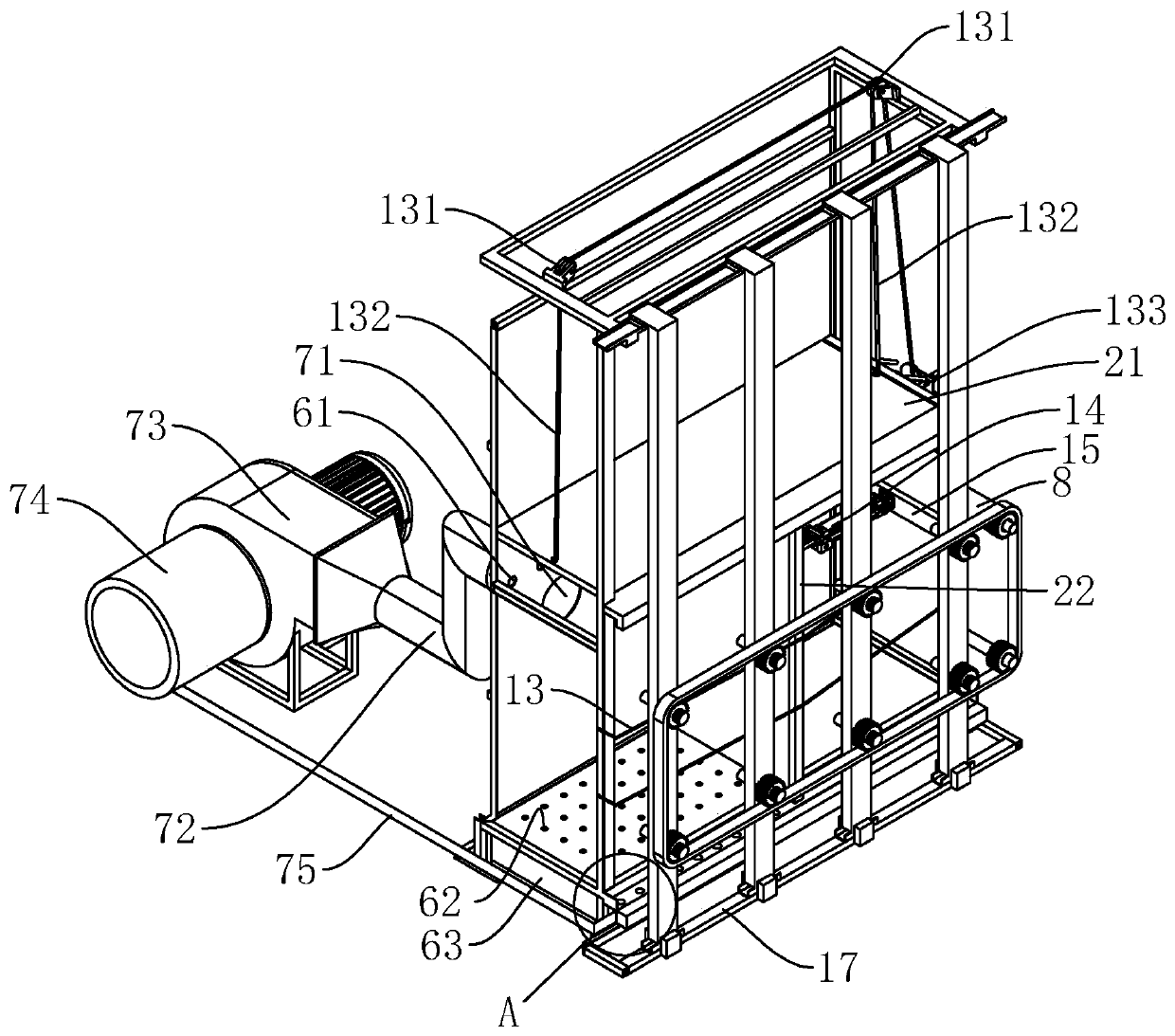

[0038] see figure 1 , a door and window physical performance testing equipment, including a box 1, a partition plate group 2 and a plurality of locking rods 3. The box body 1 is provided with an installation chamber 11 opening toward the locking rod 3 . The partition board set 2 is slidably connected inside the installation cavity 11 , and includes a first partition board 21 and a second partition board 22 that are perpendicular to each other and abut against the box body 1 . The partition plate group 2 separates the box body 1 into a cavity having the same shape and size as the object to be inspected 5 . The locking rod 3 compresses the object 5 to be inspected and the cavity separated from the box body 1 by the partition plate group 2 through the fastener 4 to form a detection cavity for detecting the physical properties of the object to be inspected 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com