Impact testing machine for ceramic pendulum bob

A technology of impact testing and ceramics, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of impact height error, impact point error, etc., achieve high accuracy, small error, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A ceramic pendulum impact testing machine of the present invention will be further described in detail below in conjunction with specific embodiments.

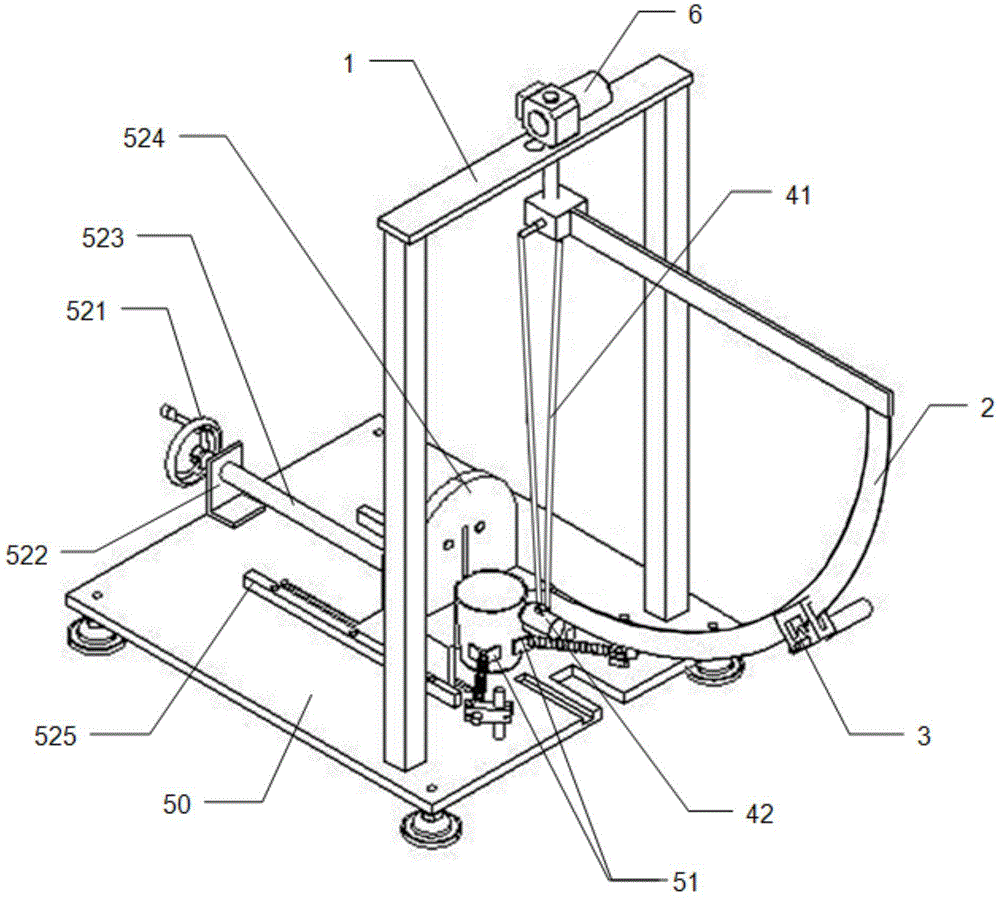

[0015] Such as figure 1 As shown, the present invention proposes a ceramic pendulum impact testing machine, comprising a support frame 1, an arc-shaped dial 2, an electromagnet 3, a pendulum 4, a fixture 5 and a linear motor 6 for fixing a sample to be tested; the fixture 5 includes The base 50, two fixed fulcrums 51 and one movable fulcrum 52, the three fulcrums are symmetrically fixed on the base 50, the movable fulcrum 52 includes a hand wheel 521, a support seat 522, a screw 523, a baffle plate 524 and a guide rail 525, and the support seat 522 is fixed Connected to the base 50, the support seat 522 is provided with a threaded hole matching the screw 523, and one end of the screw 523 passes through the threaded hole and is fixedly connected to the hand wheel 521, and the other end is fixedly connected to the baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com