Pattern cloth flaw online visual inspection method

A visual detection and defect technology, applied in the field of image processing, can solve problems such as difficult formation, complex transformation, and difficulty in eliminating texture information on cloth with large texture patterns, and achieve the effects of overcoming difficult detection, high accuracy, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

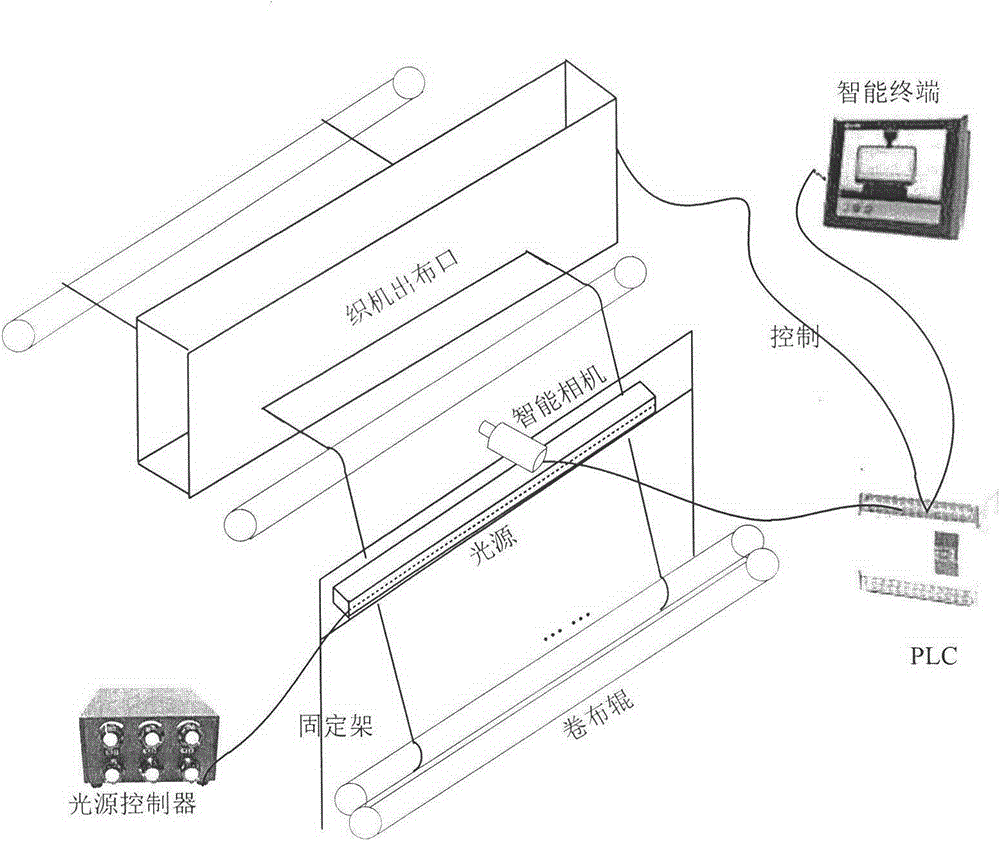

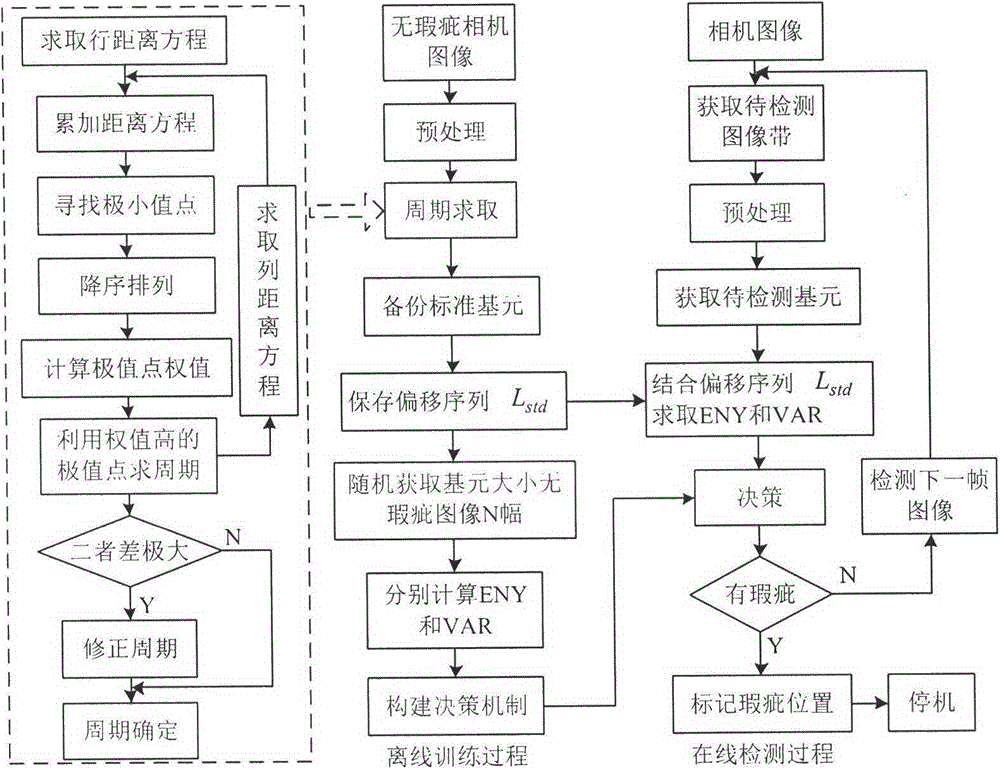

[0027] The invention is a defect detection method of patterned cloth. The detection process is divided into an offline training process and an online detection process. The installation method of the smart camera is as follows: figure 1 As shown, the overall flow chart of the algorithm is as follows figure 2 shown. In the process of offline training, the first layer of fuzzy classifier is established through accurate cycle calculation, construction of standard flawless primitive offset sequence, and feature extraction. In the online process, analyze the difference between the image block to be detected and the standard unblemished primitive offset sequence to extract energy and variance features. First, use the first-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com