A process for reducing microbial growth in contact lens storage cases

A technology of contact lenses and storage boxes, which is applied in the direction of dryers for static materials, lighting and heating equipment, dryers, etc., and can solve problems such as infectious diseases and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Wherein, referring to steps and / or features in any one or more figures in the drawings, which have the same reference numerals, those steps and / or features have the same function or operation for description purposes, unless the contrary appears intention.

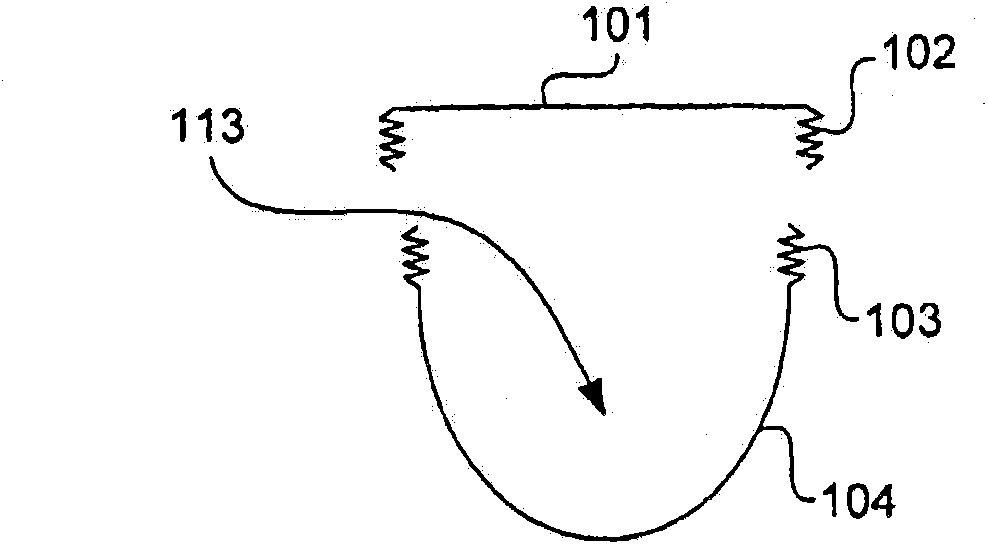

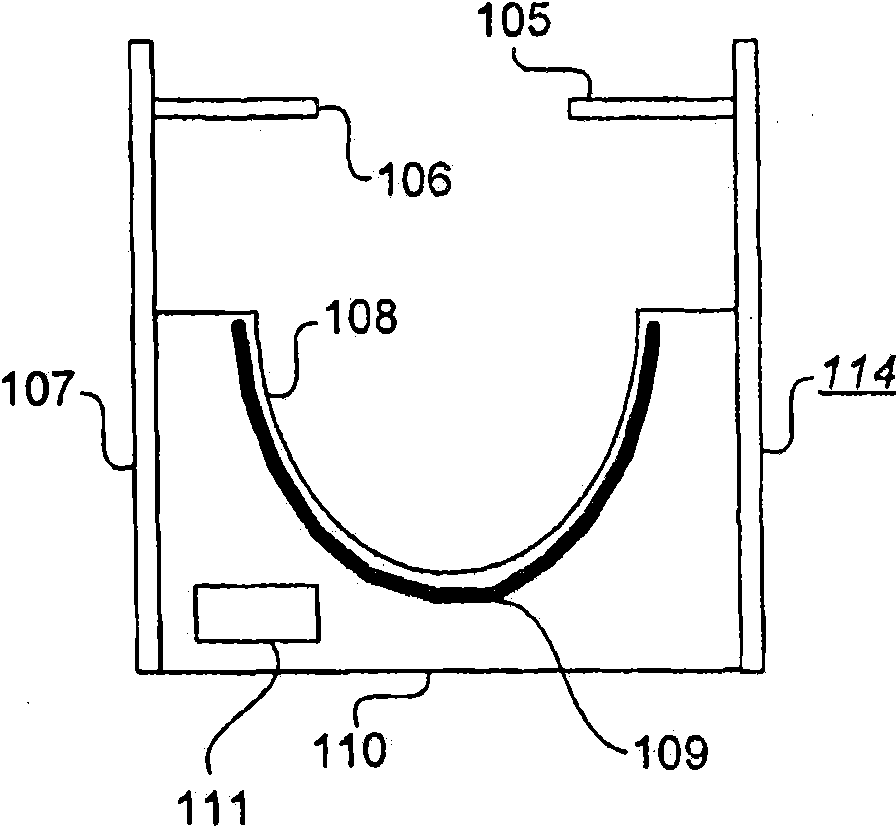

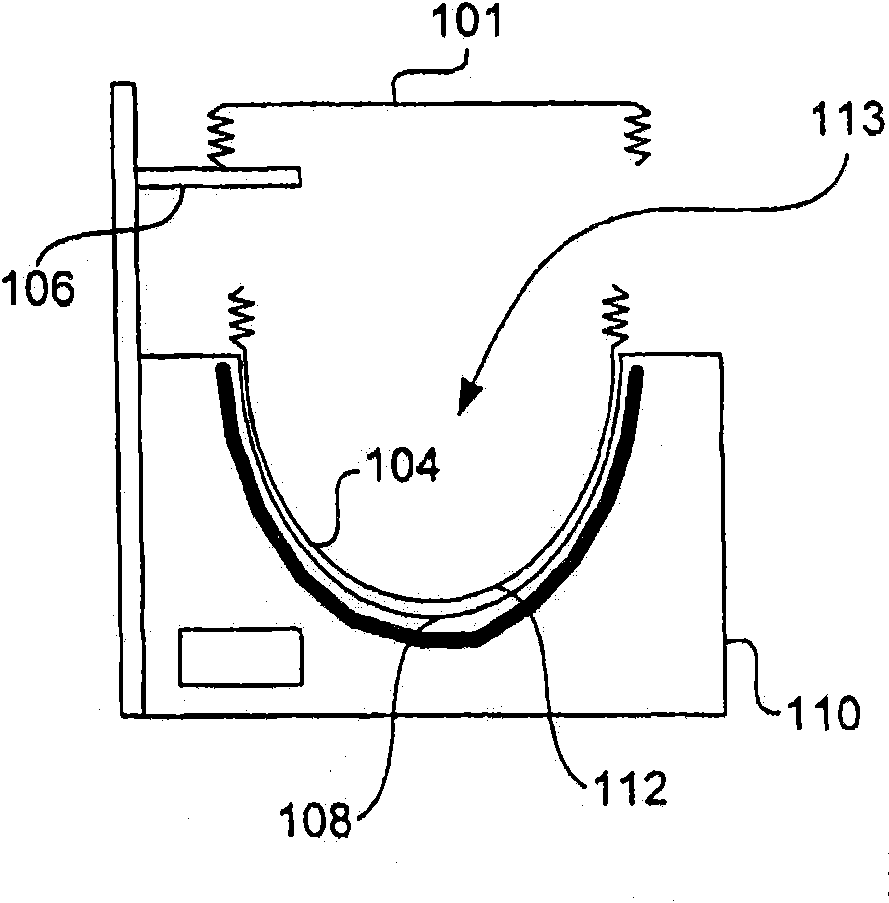

[0019] Figure 1A to 1C show prior art devices for actively drying eyeglass cases.

[0020] Figure 1A A contact lens storage case 104 and associated lid 101 are depicted. When the lenses are to be stored, contact lenses (not shown) may be placed into the well (also referred to as the cavity) 113 of the case 104 . The lid 101 has threads 102 which engage with threads 103 on the box 104 to close the box 104 when the lid 101 is attached to the box 104 .

[0021] FIG. 1B depicts device 110 having cavity 108 whose surface conforms to the exterior surface of case 104 . Thus, when the heating element 109 is activated by the power supply / control system 111 in the apparatus 110, after the cassette 104 has been inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com