Bypass valve and supercharger

A bypass valve and valve body technology, which is applied in the direction of adding non-fuel substances to the machine/engine, fuel, exhaust gas recirculation, etc., can solve the problems that foreign matter is easy to mix into the bypass flow path, and foreign matter is easy to stay, so as to improve the operation efficiency , The effect of suppressing the reduction of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

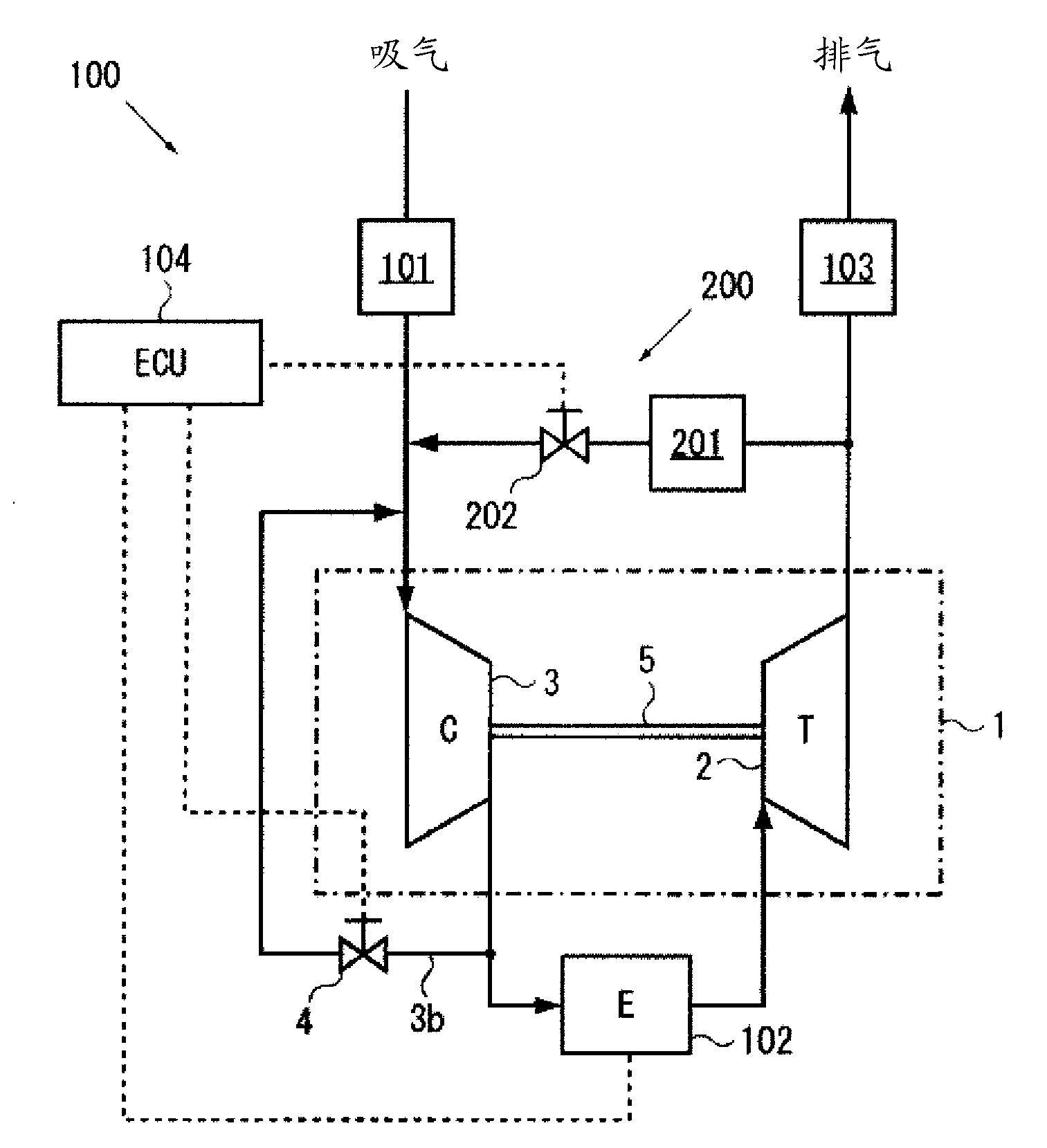

[0033] Below, refer to Figure 1 ~ Figure 6B Embodiments of the present invention will be described.

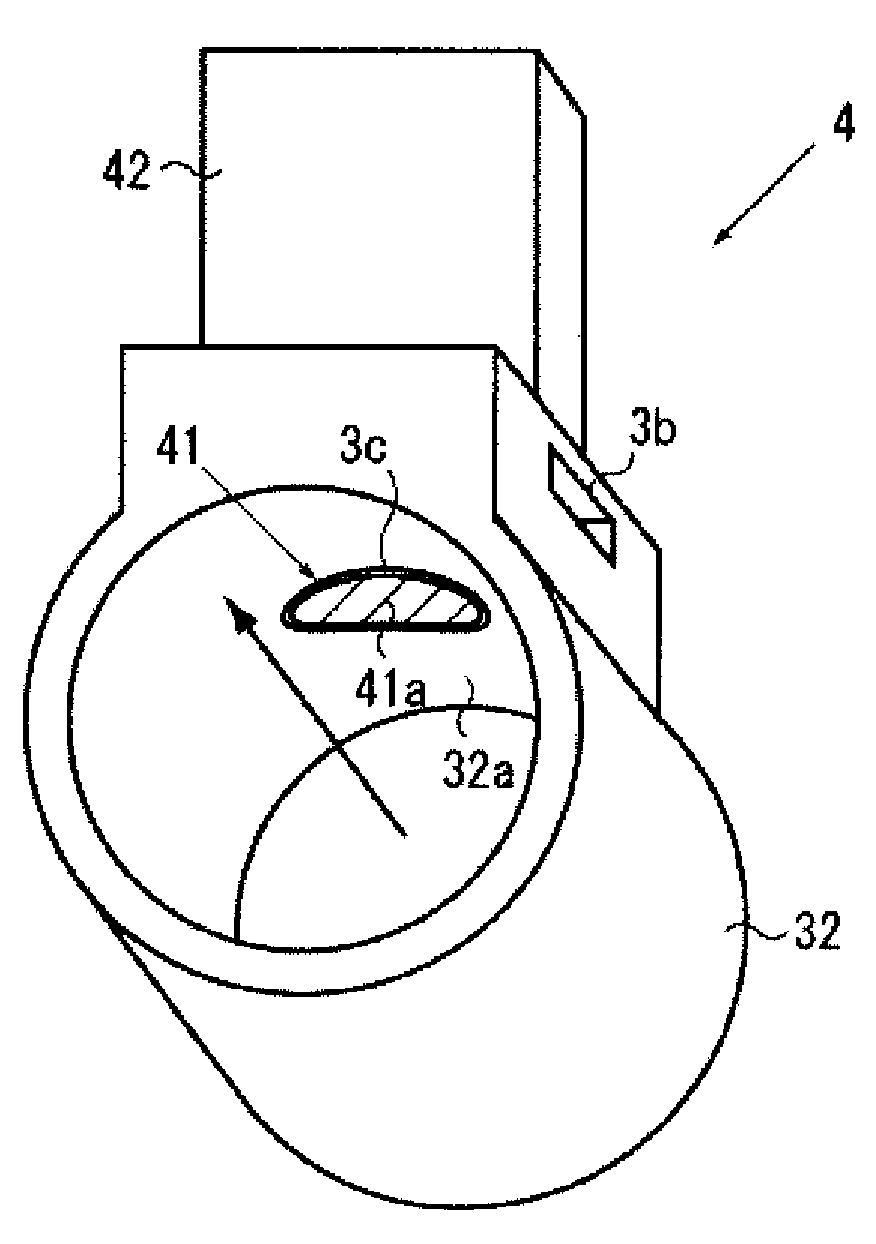

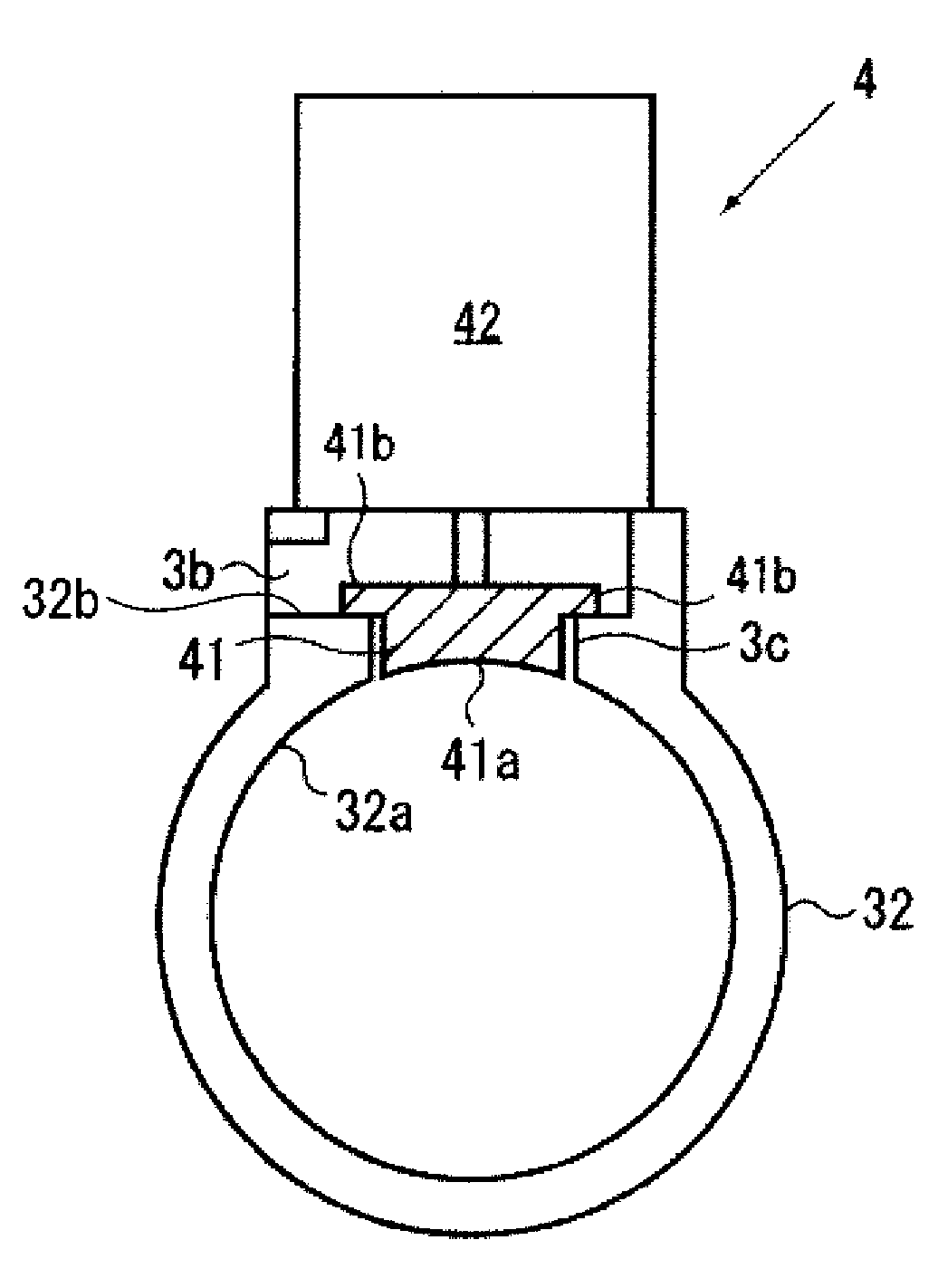

[0034] Such as figure 1 and figure 2 As shown, the supercharger 1 according to the first embodiment of the present invention includes: a gas turbine 2 to which exhaust gas is supplied from an engine 102 to rotate the movable blades 21; and a compressor 3 coaxially connected to the movable blades 21 The impeller 31 sucks in air, and the compressor casing 3 a constituting the casing of the compressor 3 has a scroll portion 32 formed in a spiral shape around the rotation axis of the impeller 31 . In addition, a bypass valve 4 is formed on the compressor housing 3a, and when the bypass valve 4 is opened, a part of the compressed air in the scroll portion 32 flows to the upstream side of the scroll portion 32 through the bypass flow path 3b. The flow is divided, and the compressed air in the scroll portion 32 is sent to the downstream side in the closed state. The bypass val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com