Slide bearing

A technology for sliding bearings and bearings, which is applied in the direction of sliding contact bearings, bearings, and bearings for rotating motion, etc., can solve the problems of sliding bearing damage, sliding bearing failure, etc., and achieve the effect of easy manufacturability or assemblability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

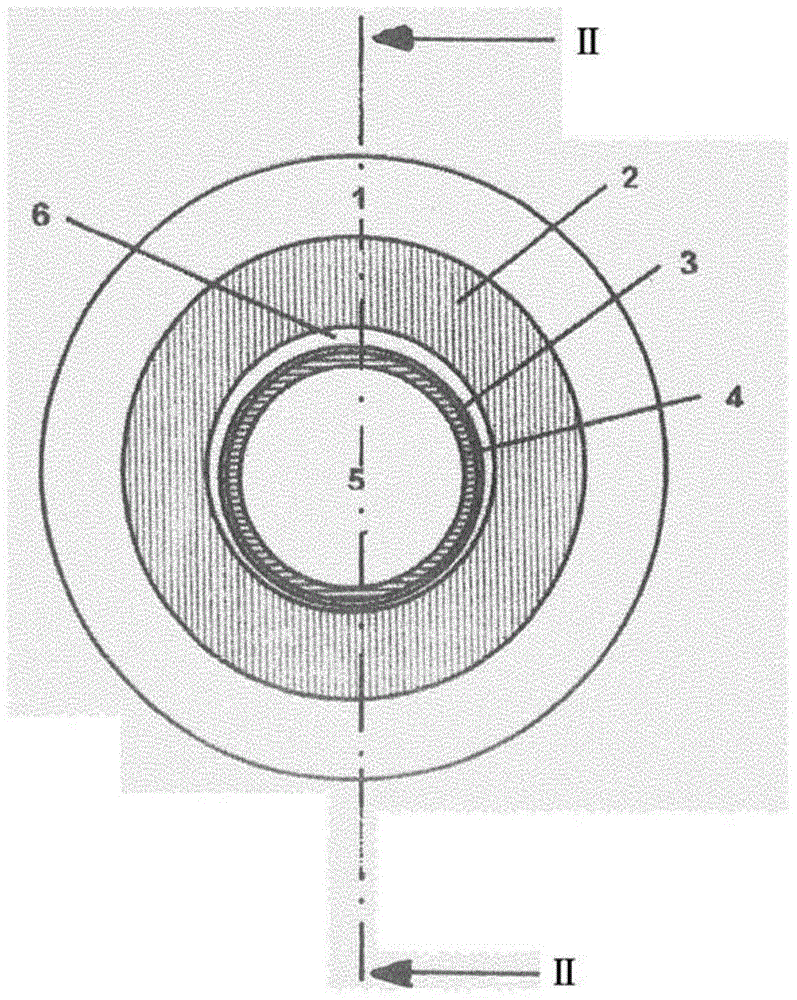

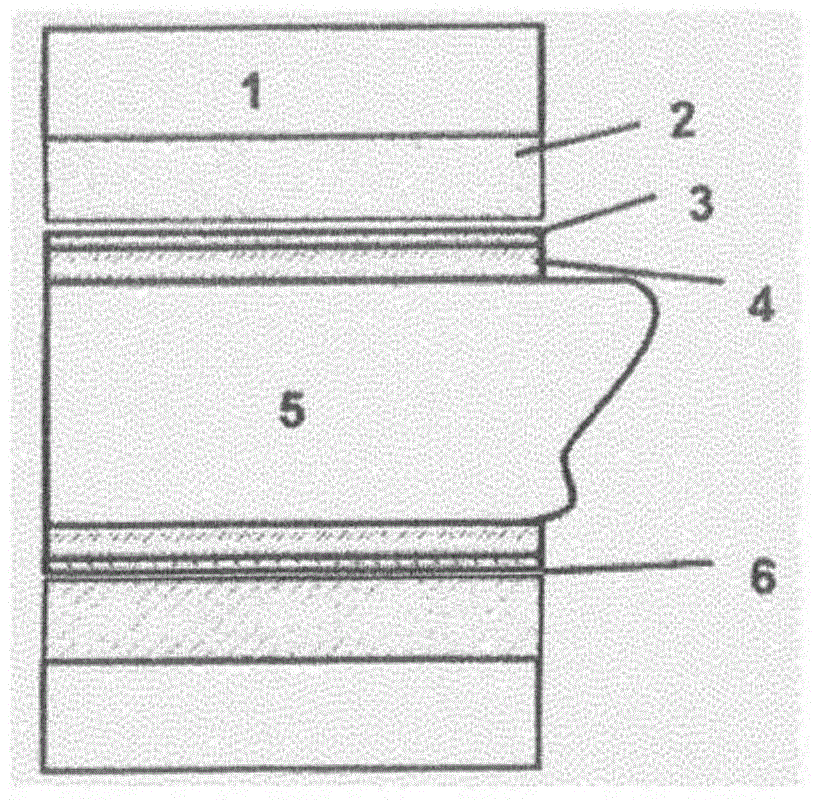

[0022] exist figure 1 As can be seen in , the slide bearing is surrounded on the outside by a housing 1 which acts as a bearing shell. The bearing outer ring 2 surrounded by the housing 1 is held by the housing 1 . The bearing inner ring 4 carrying the hard material layer 3 rests in the bearing outer ring 2 . The bearing inner ring 4 itself is shrink-fitted onto the shaft 5 . Finally, a bearing gap 6 is visible between the hard material layer 3 and the bearing outer ring 2 . A lubricant (not shown in the drawing) is introduced into the bearing gap 6 and forms a lubricating film during operation.

[0023] Thus, in the exemplary embodiment, the shaft 5 with its bearing inner ring 4 forms the rotational friction part of the slide bearing. On the contrary, the housing 1 forms with its bearing outer ring 2 the counterpart of the sliding bearing. In this exemplary embodiment, the bearing inner ring 4 carries on the shaft 5 a hard material layer 3 which can consist of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com