Patents

Literature

36results about How to "High wear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

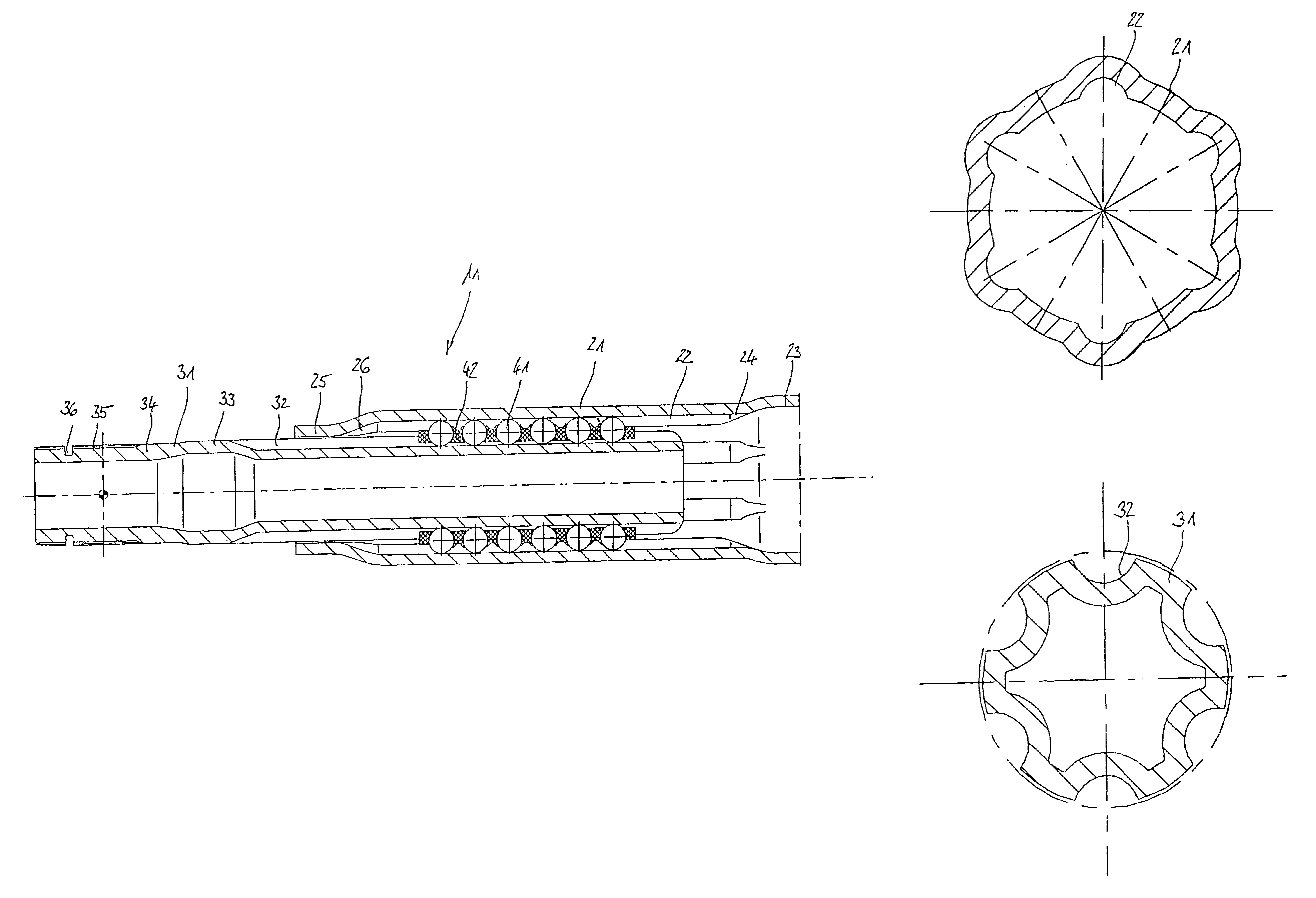

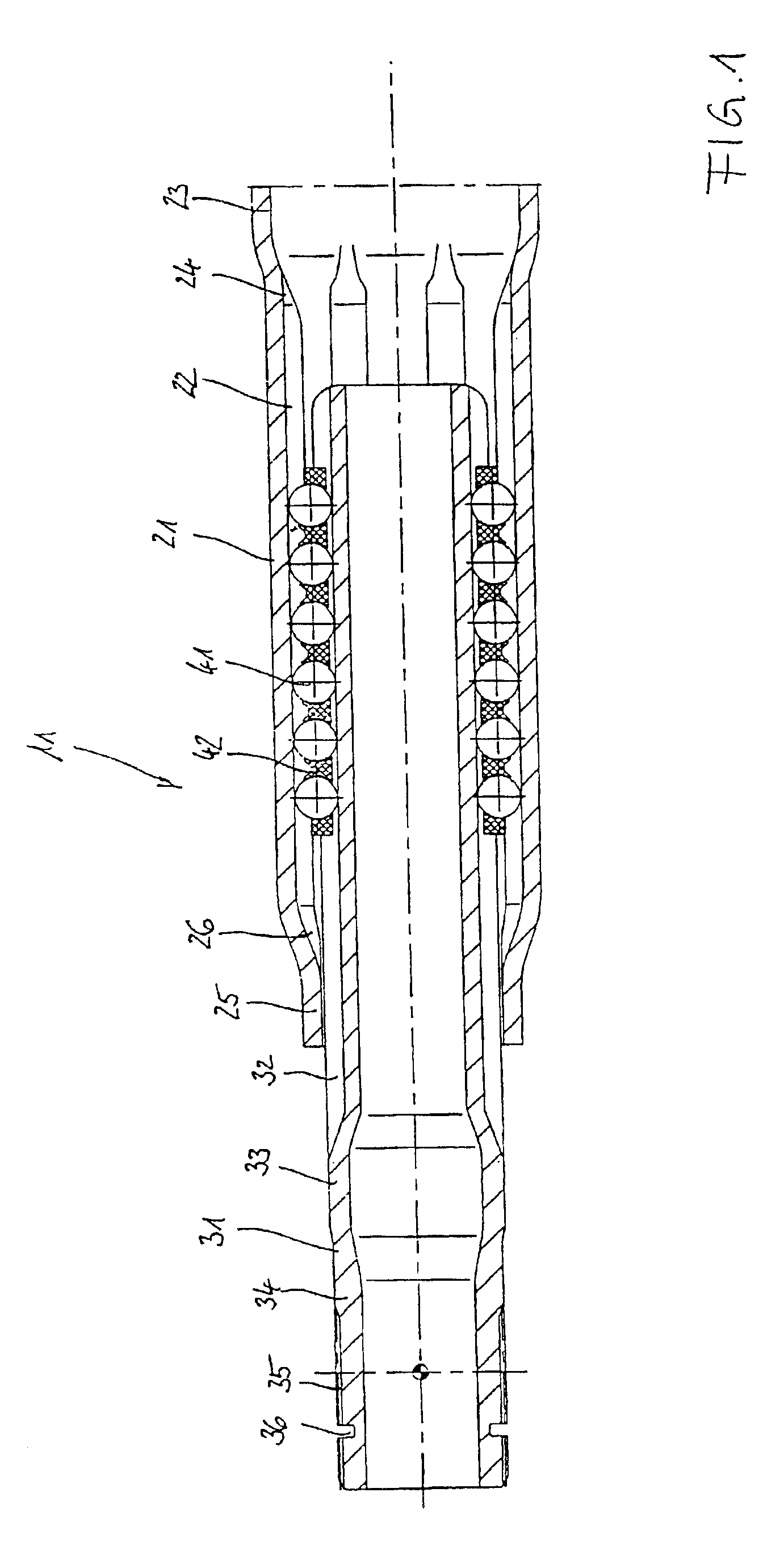

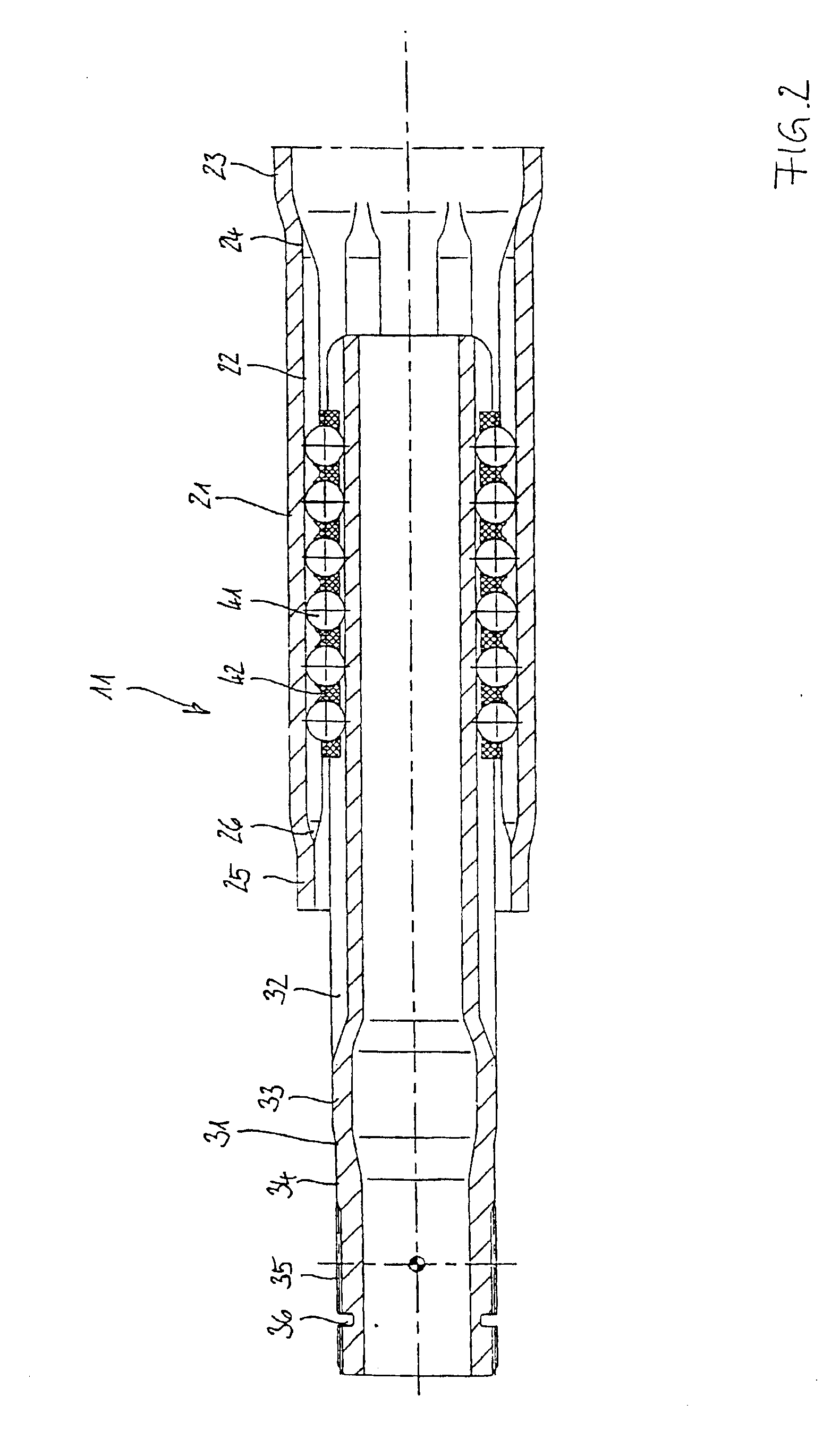

Longitudinal plunging unit with a hollow profiled journal

InactiveUS6918838B2High strengthCompact designYielding couplingShaftsEngineeringMechanical engineering

A longitudinal plunging unit (11) for torque transmitting purposes in a shaft assembly, comprising an outer profiled sleeve (21) having circumferentially distributed, inner, longitudinally extending first ball grooves (22) to be connected to a first attachment part, a profiled journal (31) positioned inside the outer profiled sleeve (21) and having circumferentially distributed, outer, longitudinally extending second ball grooves (32) to be connected to a second attachment part, groups of balls (41) arranged in pairs of first and second ball grooves (22, 32), and a sleeve-shaped ball cage (42) which is positioned in the annular space between the profiled sleeve (21) and the profiled journal (31) and which fixes the groups of balls (41) in their respective positions relative to one another. The profiled journal (31) is a hollow journal comprising a material with a substantially uniform wall thickness with a maximum deviation of ±15%.

Owner:GKN LOBRO

Technique for preparing aluminium sol

InactiveCN1445167AReduce manufacturing costGood adhesionAluminium chloridesAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

A process for preparing aluminium sol includes such steps as proportionally mixing alumina and / or aluminium hydroxide and / or another aluminium source with sulfuric acid, reaction at 80-150 deg.C for 2-18 hr while stirring, adding water, aqueous solution of hydrochloric acid, or the aqueous solution containing aluminium chloride, adding aluminium, and reaction at 80-150 deg.c and 1-5 atmos for 3-40 hr. Its advantages are low cost, and ihgh viscosity.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Selective catalytic reduction flue gas denitration catalyst and production method thereof

ActiveCN101428240AImprove wear resistanceSimple processCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsFlue gasHoneycomb

The invention relates to a gas denitration catalyst, in particular to a honeycomb denitration catalyst based on the selective catalytic reduction (SCR) technique, and a production method thereof. After a drying monomer with the catalyst composition is sawed, the catalyst is prepared through the following steps: (1) one end part of the monomer is put in an aluminum salt water solution with the density being 1.41-1.45kg / L for being impregnated about 5-12 seconds; (2) a blower is used to blow for 15-25 seconds, so as to blow off superfluous hardening liquid on the surface of the impregnated end part of the monomer; and (3) the monomer after being impregnated in the hardening liquid is calcined in a calciner and hardened. Therefore, the production process of the invention is simple and costs little, and the abrasion strength of the catalyst improved.

Owner:CHENGDU DONGFANG KWH ENVIRONMENTAL PROTECTION CATALYSTS

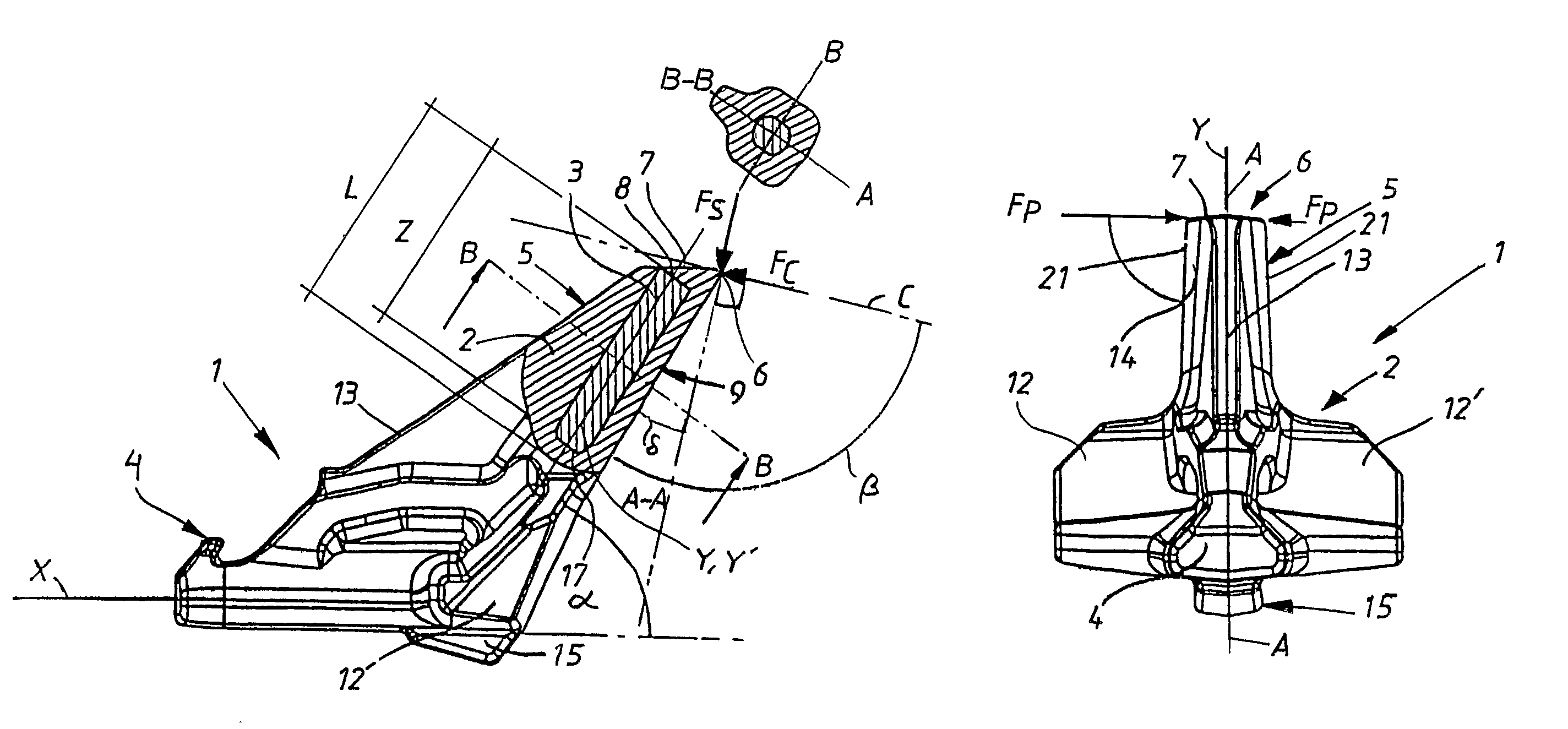

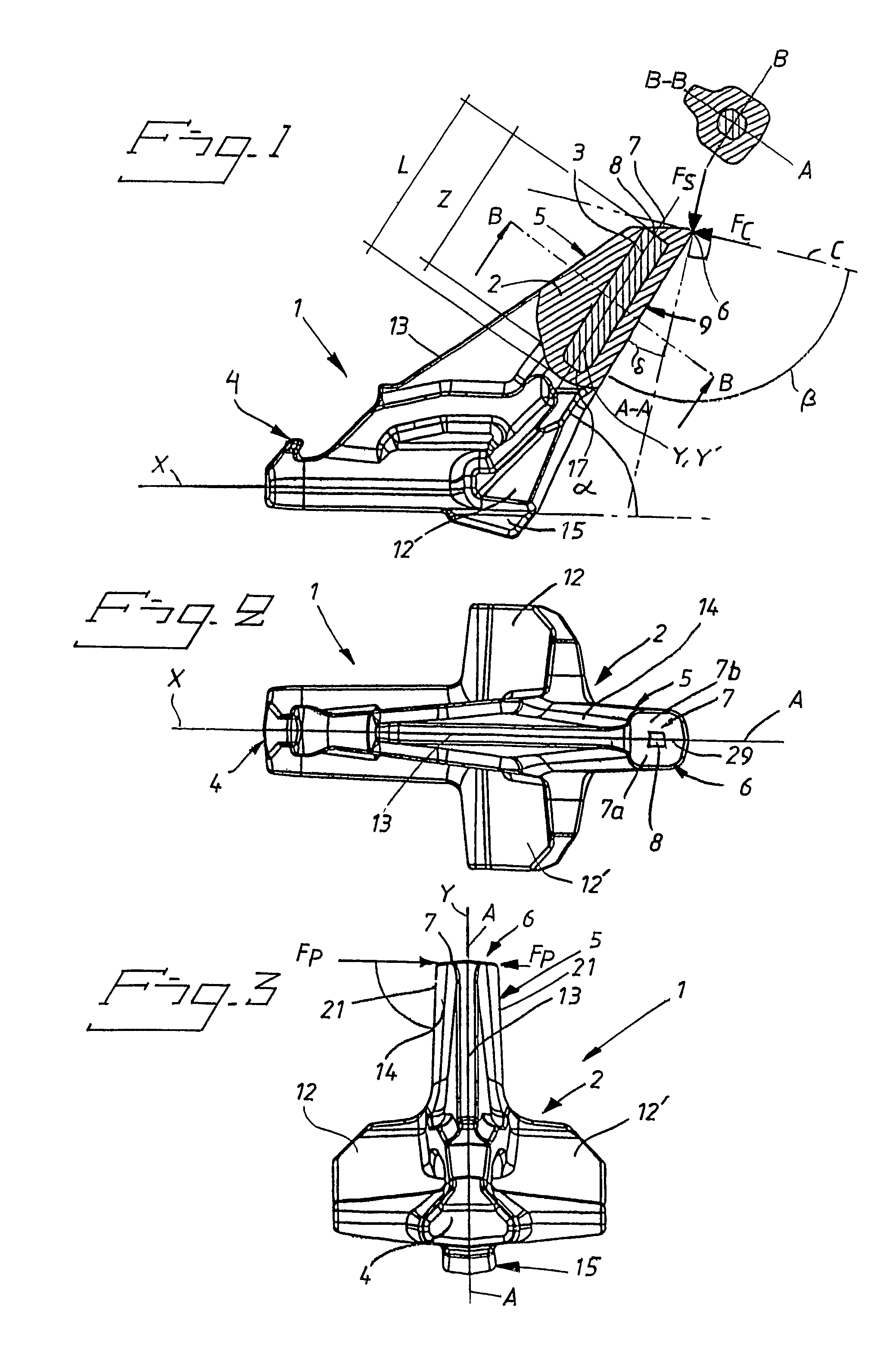

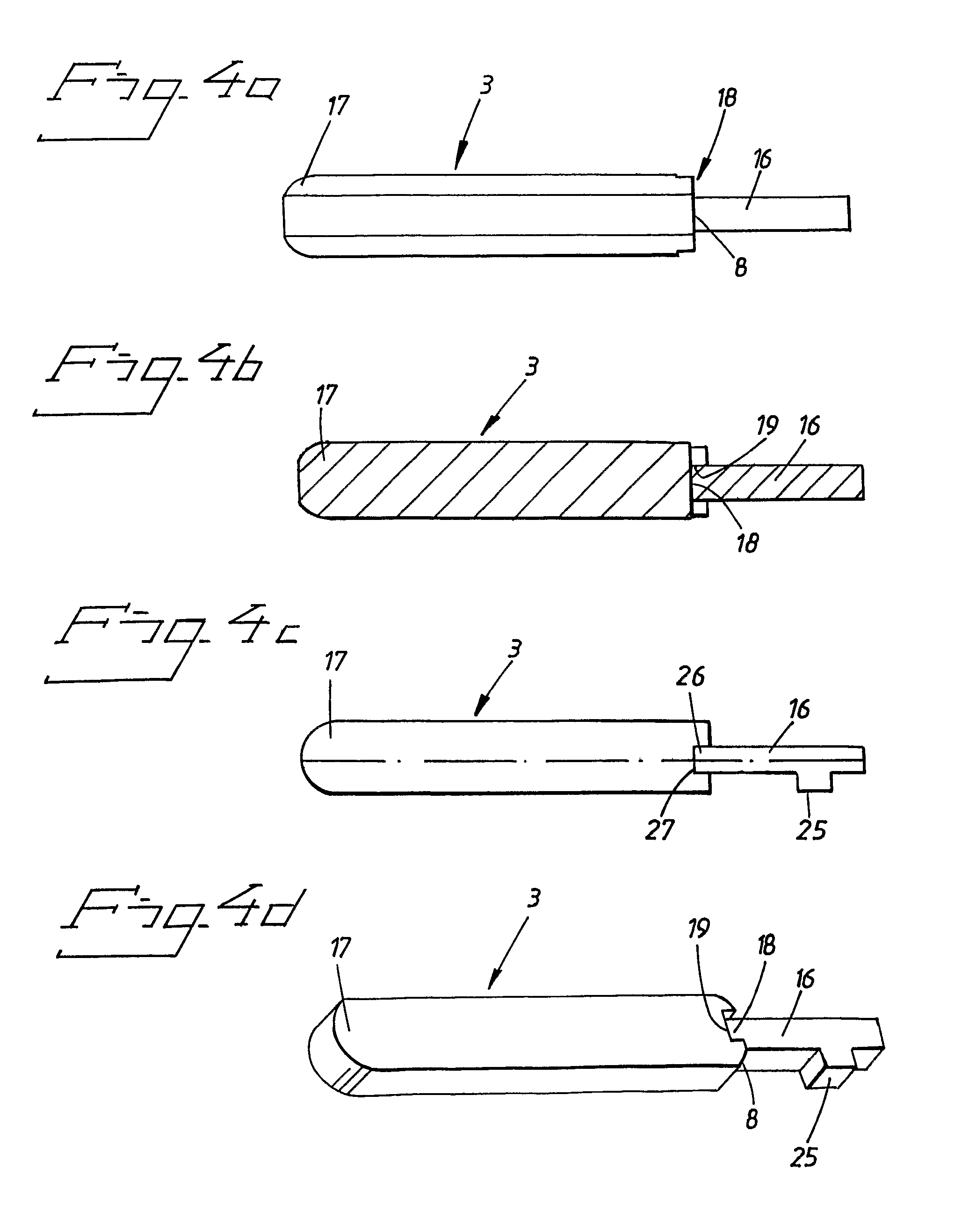

Self-sharpening, auto-signalling wearing part

ActiveUS7930844B2Improve performanceEasy to wearSoil-shifting machines/dredgersStone-like material working toolsHard metalSharpening

Self-sharpening wearing part having improved abrasion resistance and strength, which wearing part comprises at least a first and a second material part. The first material part is constituted by a casting body and the second material part is comprised of at least one elongated hard metal rod which is fixed in the first material part. The wearing part produces an auto-signal when the part must be changed due to wear.

Owner:COMBI WEAR PARTS AB +1

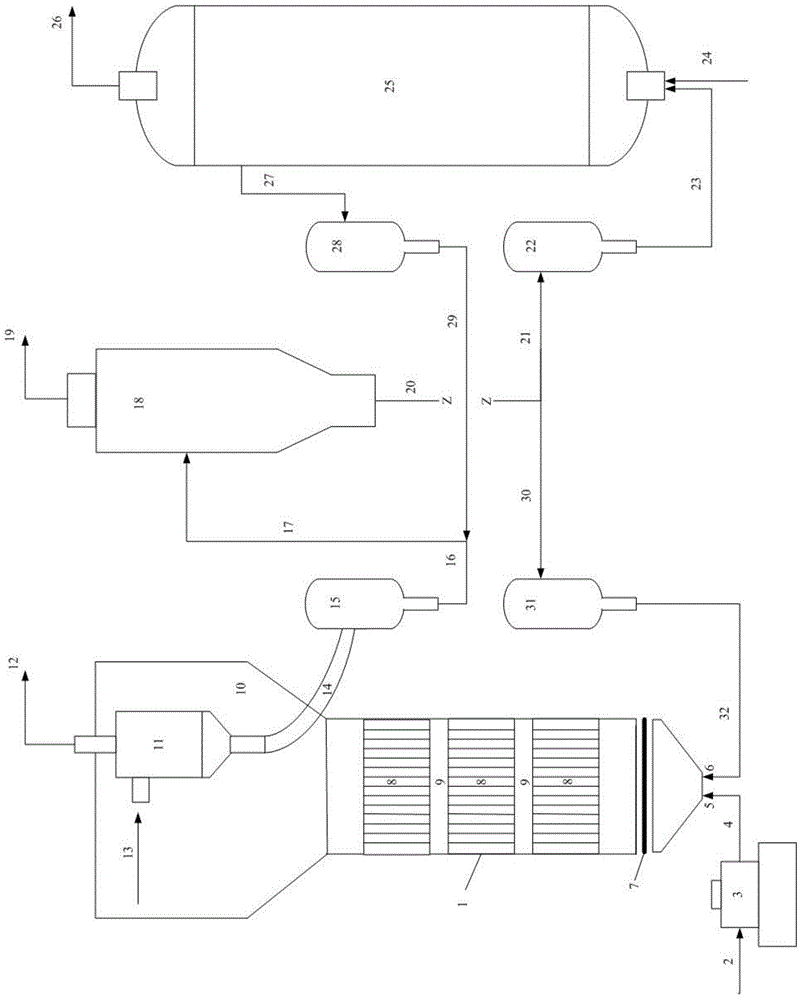

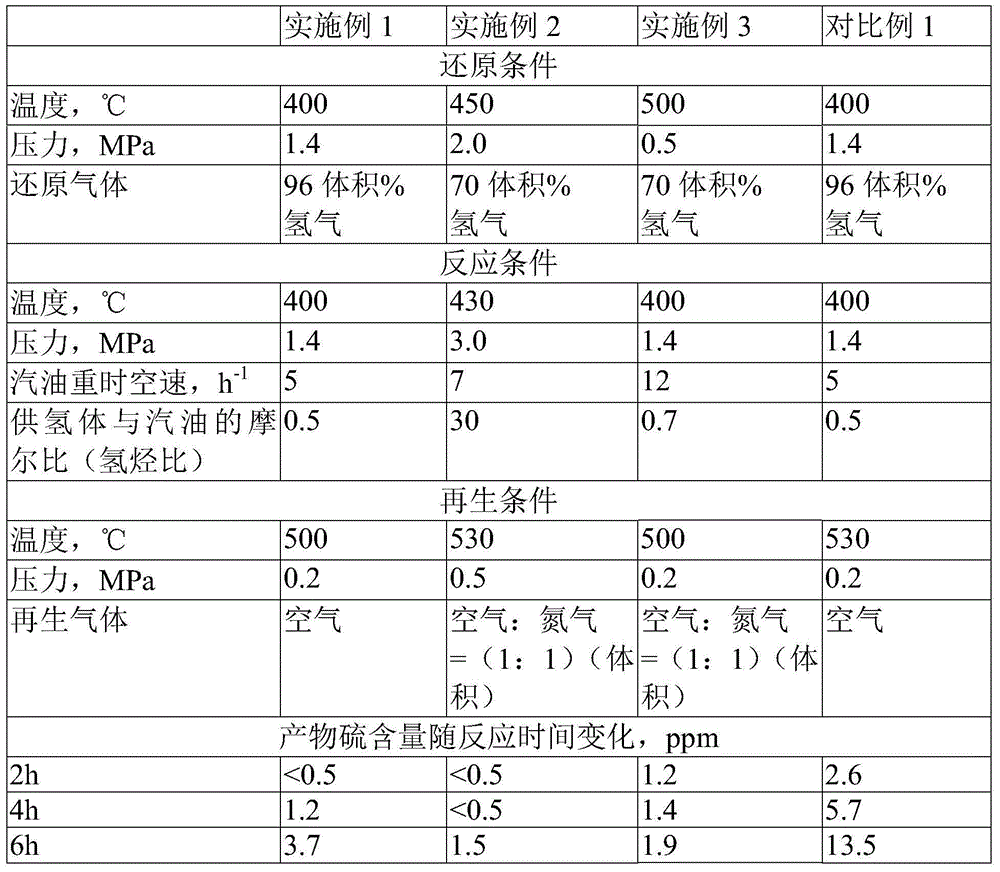

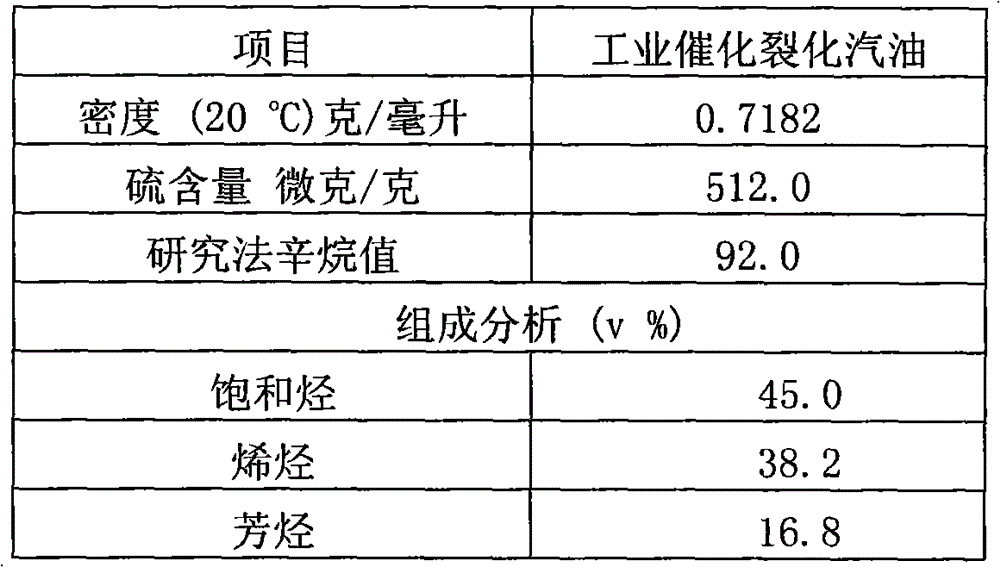

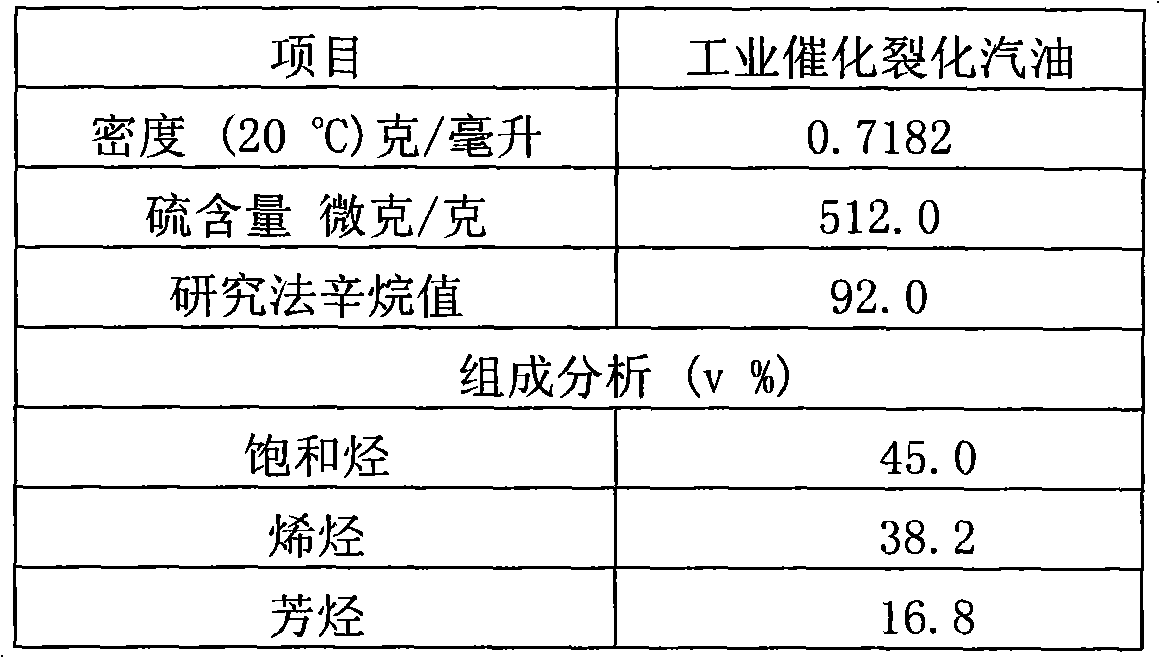

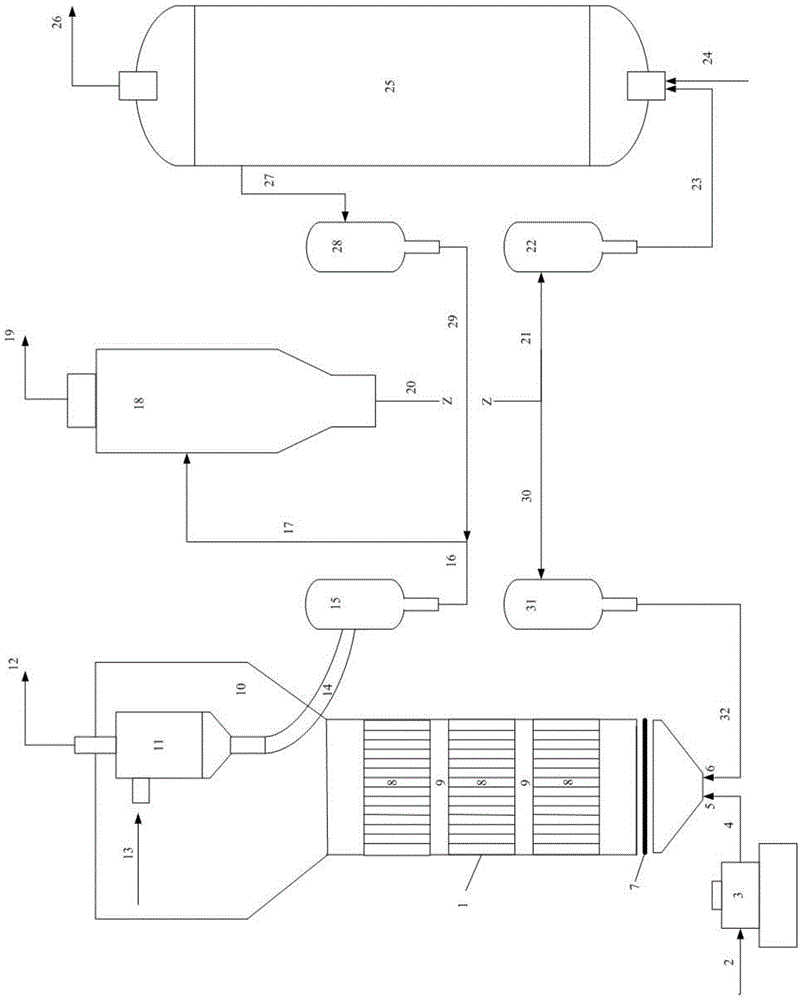

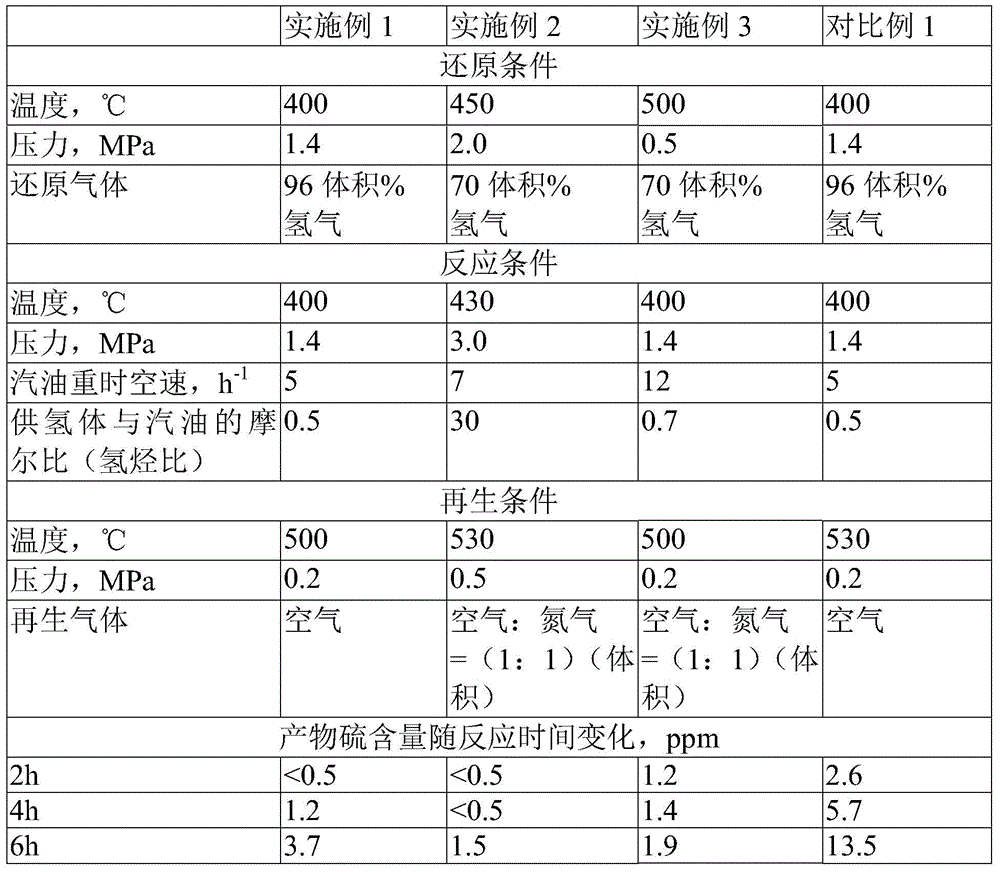

Catalyst system for sulfur-hydrocarbon-containing desulfurization, sulfur-hydrocarbon-containing desulfurization method and device for method

ActiveCN104549303ANot easy to loseReduce unit consumptionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMicrosphereSulfur

The invention discloses a catalyst system for sulfur-hydrocarbon-containing desulfurization, a sulfur-hydrocarbon-containing desulfurization method using the catalyst system and a device for implementing the method. The catalyst system comprises a desulfurization auxiliary and a monolithic catalyst, wherein the active ingredient coating of the monolithic catalyst comprises 30-90wt% of active metal and 10-70wt% of substrate; the desulfurization auxiliary comprises 5-35wt% of alumina, 5-35wt% of a silicon oxide source and 30-90wt% of oxide of at least one metal of IIB, VB and VIB families; the desulfurization auxiliary is microspheres having average grain size of 20-200 microns; the weight ratio of the desulfurization auxiliary to the active ingredient coating of the monolithic catalyst is (1-9):1. The catalyst system provided by the invention has better desulfurization activity and desulfurization stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slide bearing

InactiveCN103608598AChanging Dipping BehaviorReduce frictionShaftsLiquid cushion bearingsEngineeringMechanical engineering

The invention relates to a slide bearing comprising a rotating friction partner, a counterpart and a lubrication film between the friction partner and the counterpart, wherein the friction partner or the counterpart is coated with a hard material.

Owner:SCHAEFFLER TECH AG & CO KG

Method for cutting silicon wafer through low-particle electroplating gold wire

ActiveCN104441282AImprove cutting effectImprove pass rateFine working devicesVibration amplitudeEconomic benefits

The invention discloses a method for cutting a silicon wafer through a low-particle electroplating gold wire. The method includes the first step of bar adhesion, the second step of wire cutting, the third step of glue disengaging, the fourth step of wafer inserting, the fifth step of cleaning and the sixth step of verifying. According to the method, the silicon wafer is cut through the low-particle electroplating gold wire with a particle height of 6 microns to 12 microns; meanwhile, an existing production process is improved, the linear speed in the wire cutting step is increased, the steel wire feed and return distance is increased, the cooling temperature of cooling liquid is lowered; by means of the method, the abnormity, caused by the particle vibration amplitude generated by electroplating gold wire swinging, of the surface of the silicon wafer can be reduced, the cutting capacity of the low-particle electroplating gold wire can be reduced, it is ensured that the yield of the silicon wafer cut by the low-particle electroplating gold wire and the yield of the silicon wafer cut by an intermediate-particle electroplating gold wire are located at the same level, and the aims of increasing the silicon wafer yield, ensuring the high production efficiency and increasing the economic benefits are achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

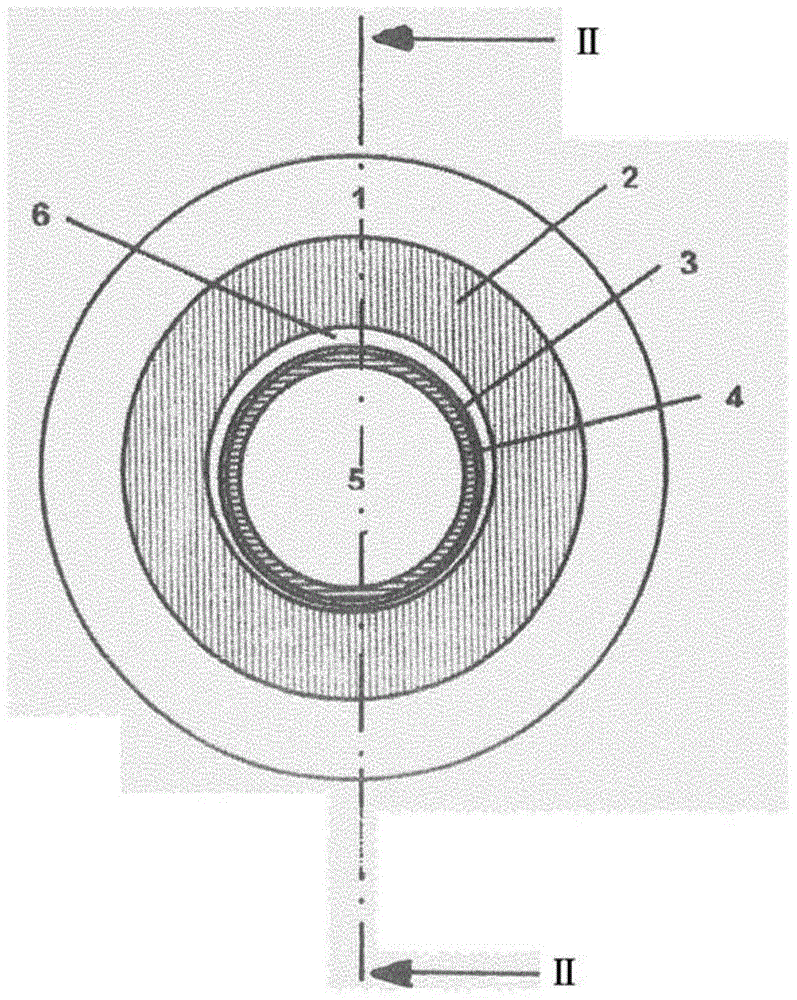

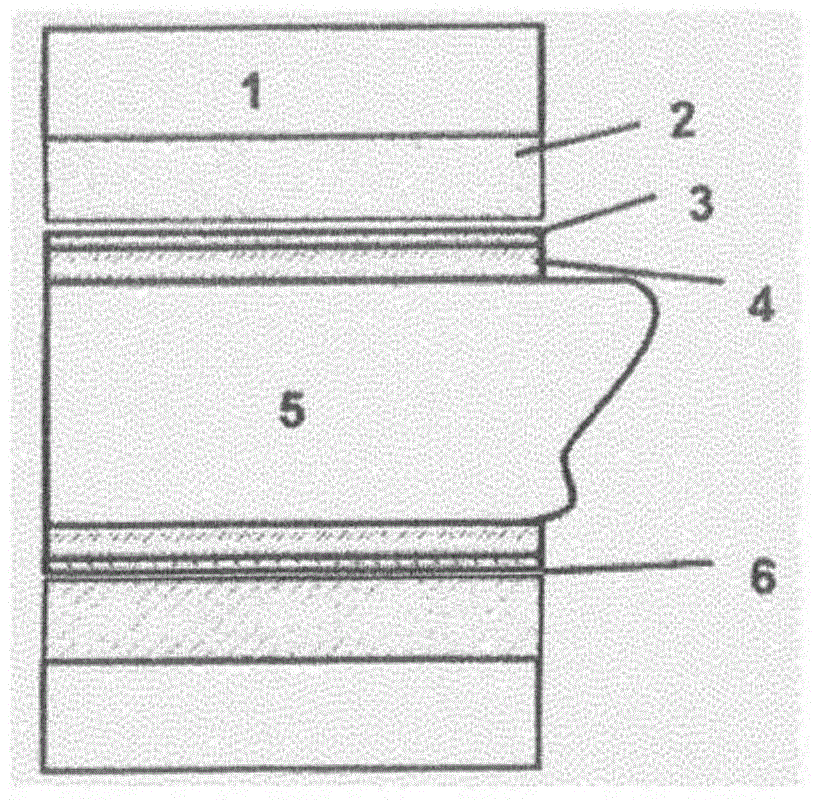

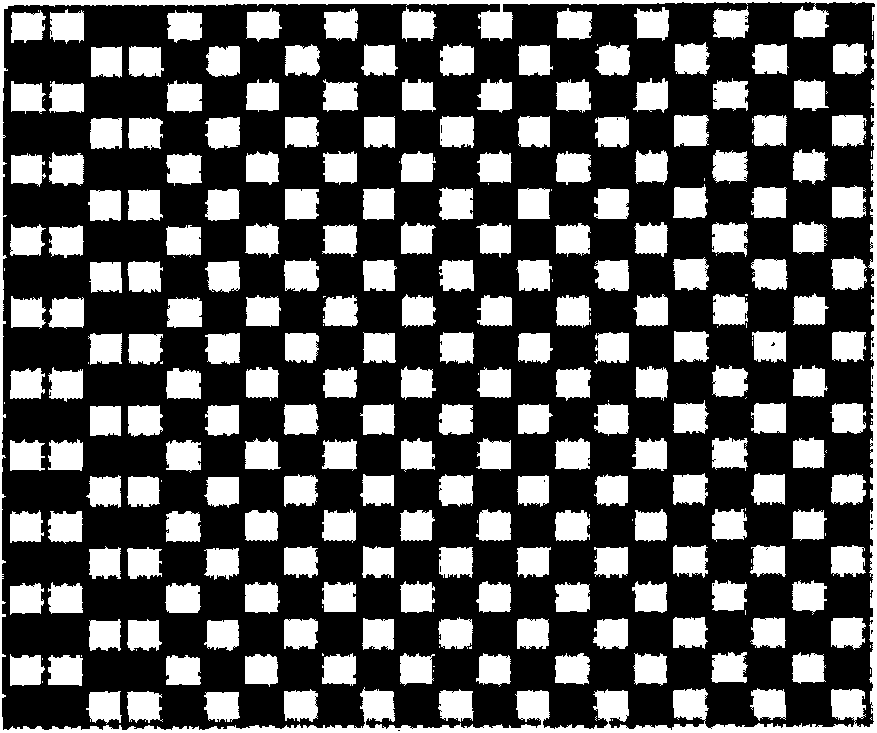

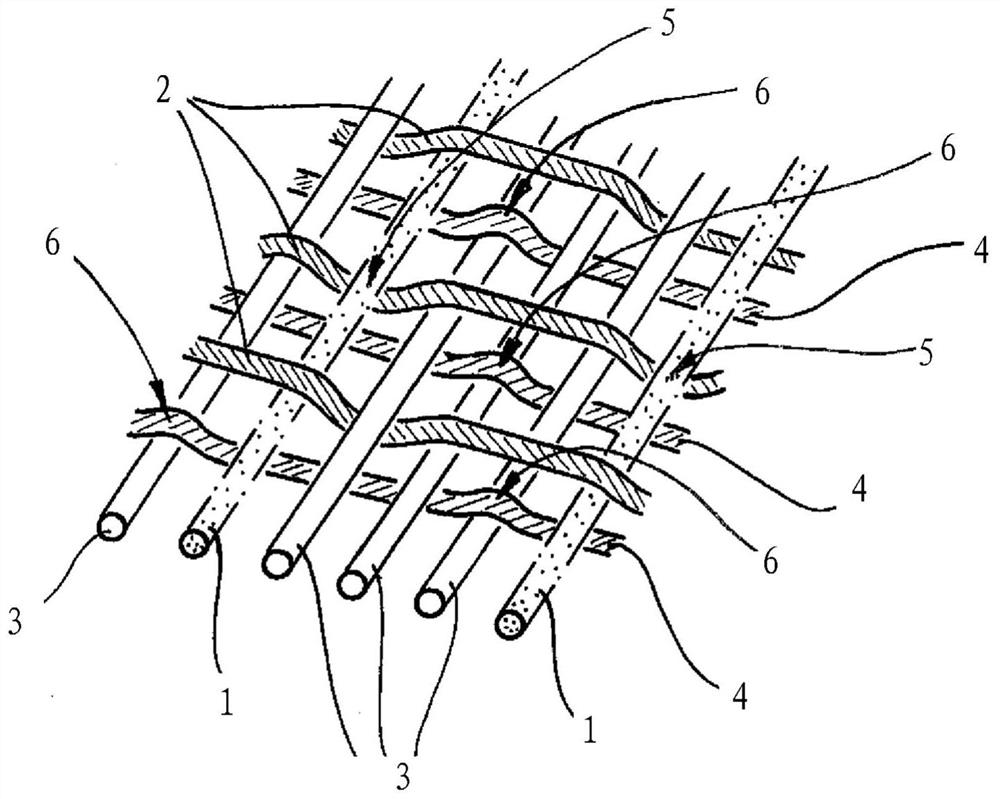

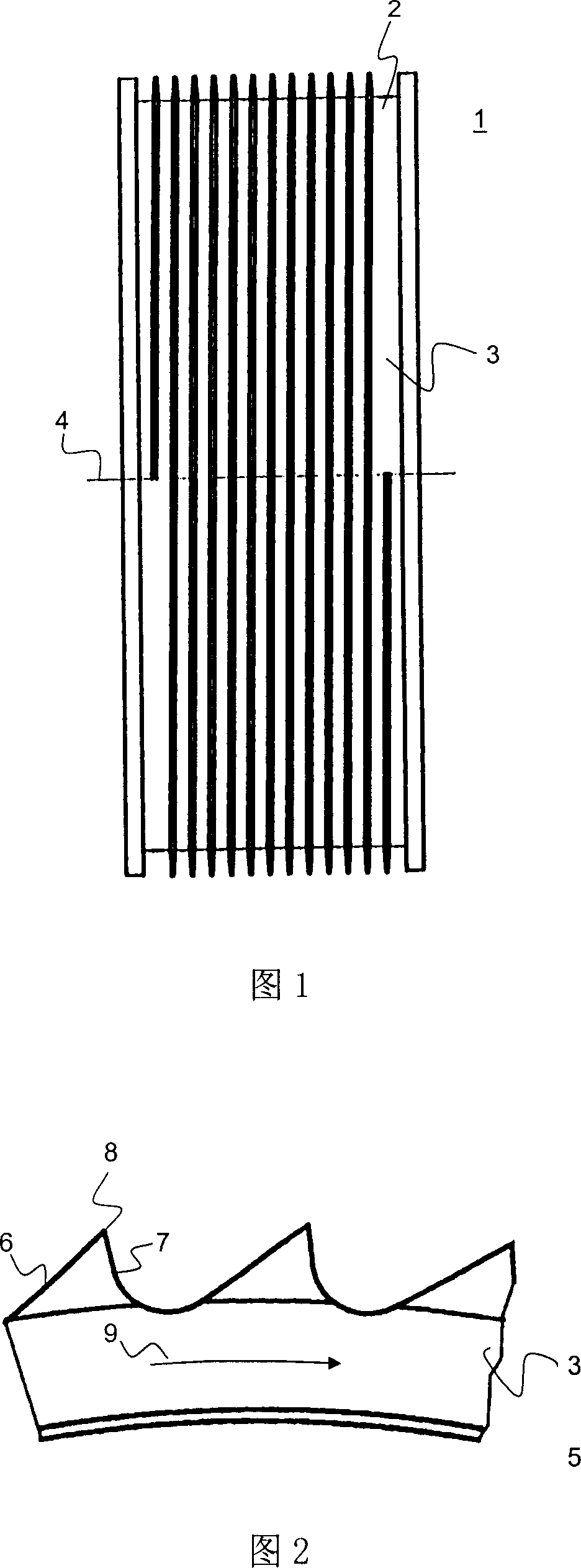

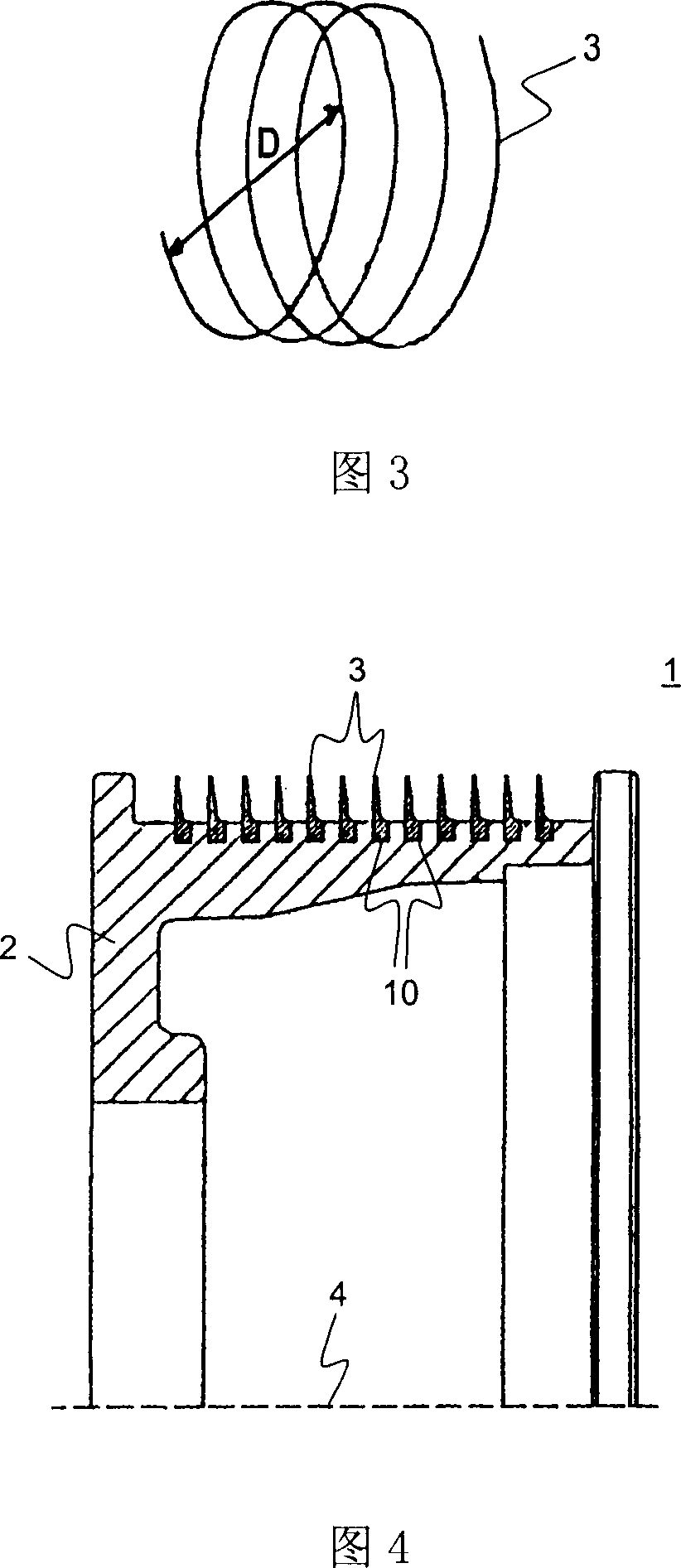

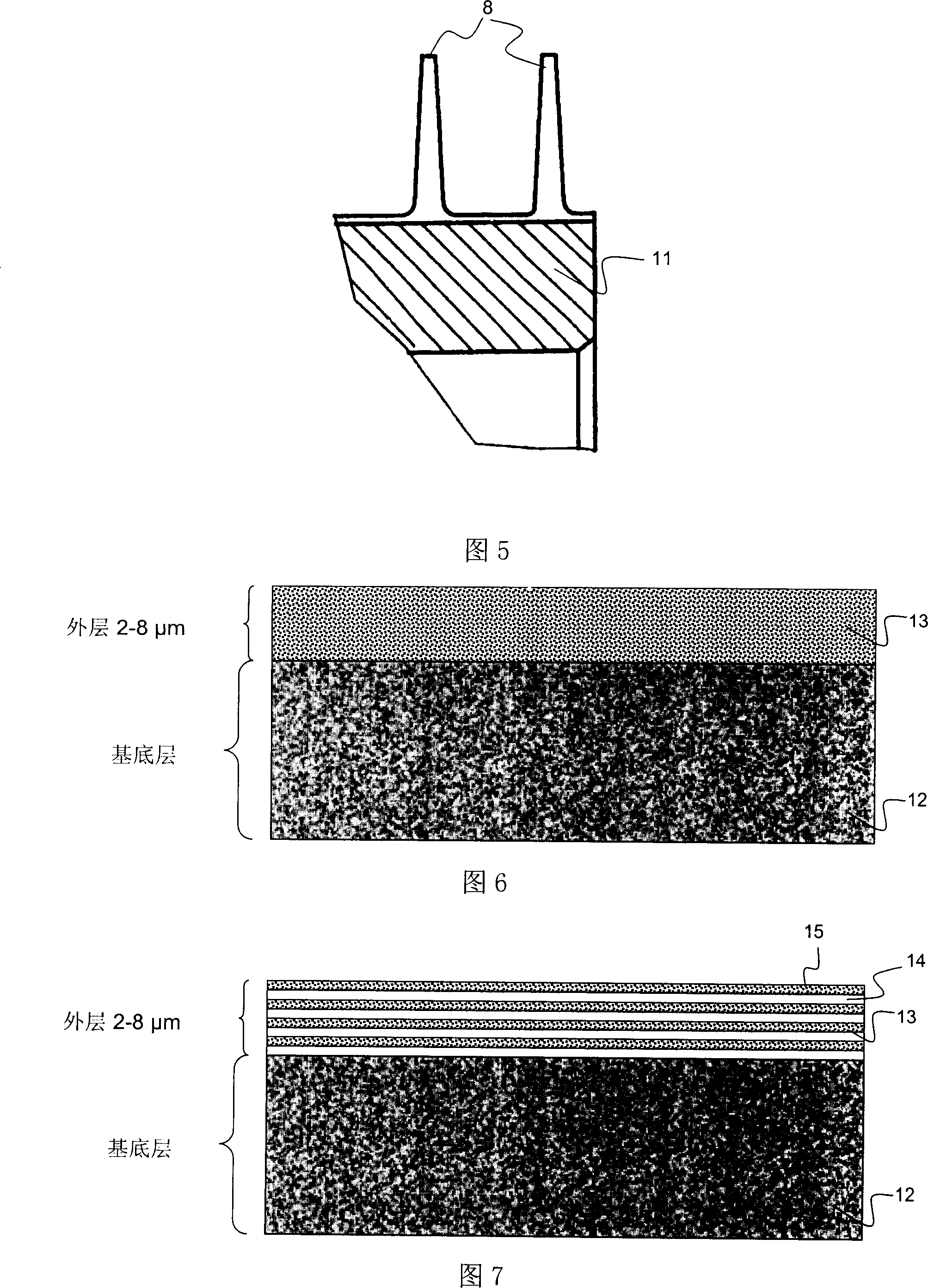

Opening device for spinning machines

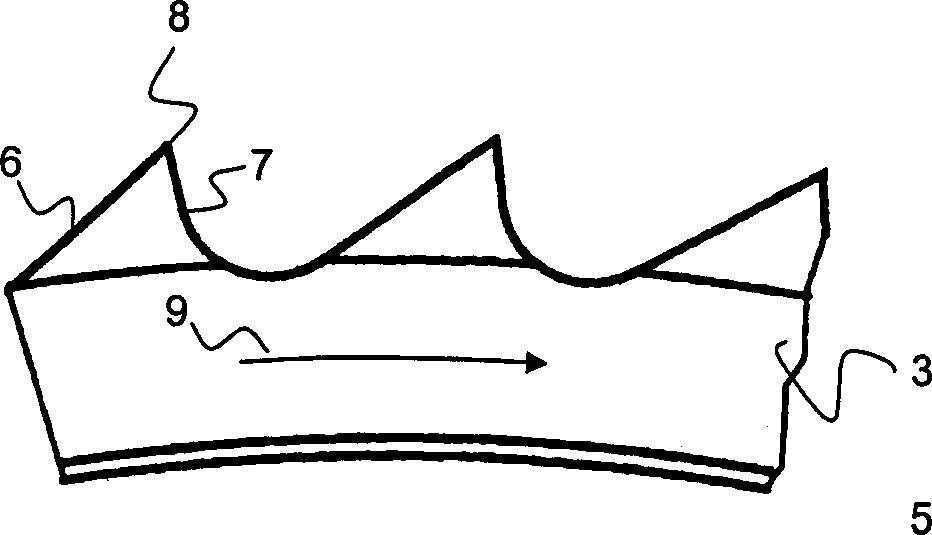

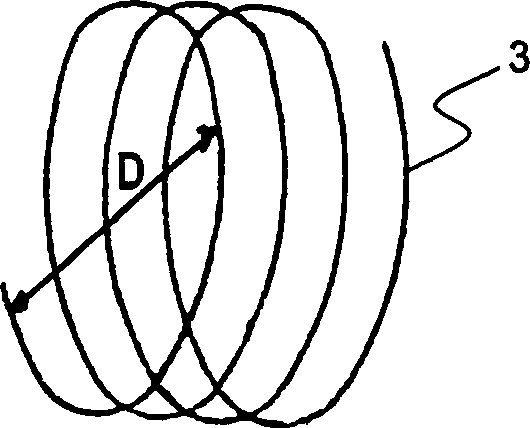

InactiveCN1789508AHigh wear strengthHigh hardnessVacuum evaporation coatingSputtering coatingFiberEngineering

The invention relates to a spinning machine, in particular to an opening device for an open-end spinning machine, which opening device is equipped with metal clothing (3) or clothing loops (3) or clothing loops ( 11), the opening device of the present invention is characterized in that the metal card clothing (3) is pre-bent according to the geometry of the support ring (2), and the card clothing ring (11) has the required workpiece geometry, and the corresponding The surface of the workpiece has a structure of at least two layers, wherein an outer layer (13) is a hard material layer, the hard material layer is wholly or partly composed of a particularly hard hard material component, and is placed on the base layer (12) above.

Owner:利特英格纺织机械制造股份公司

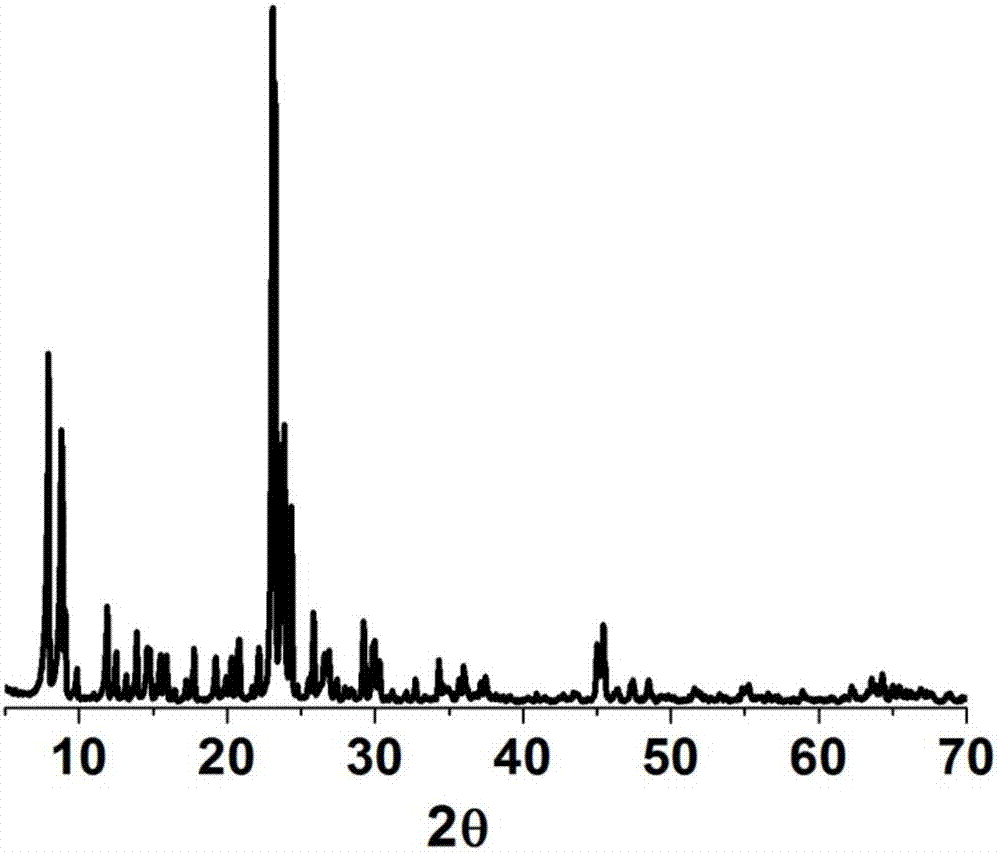

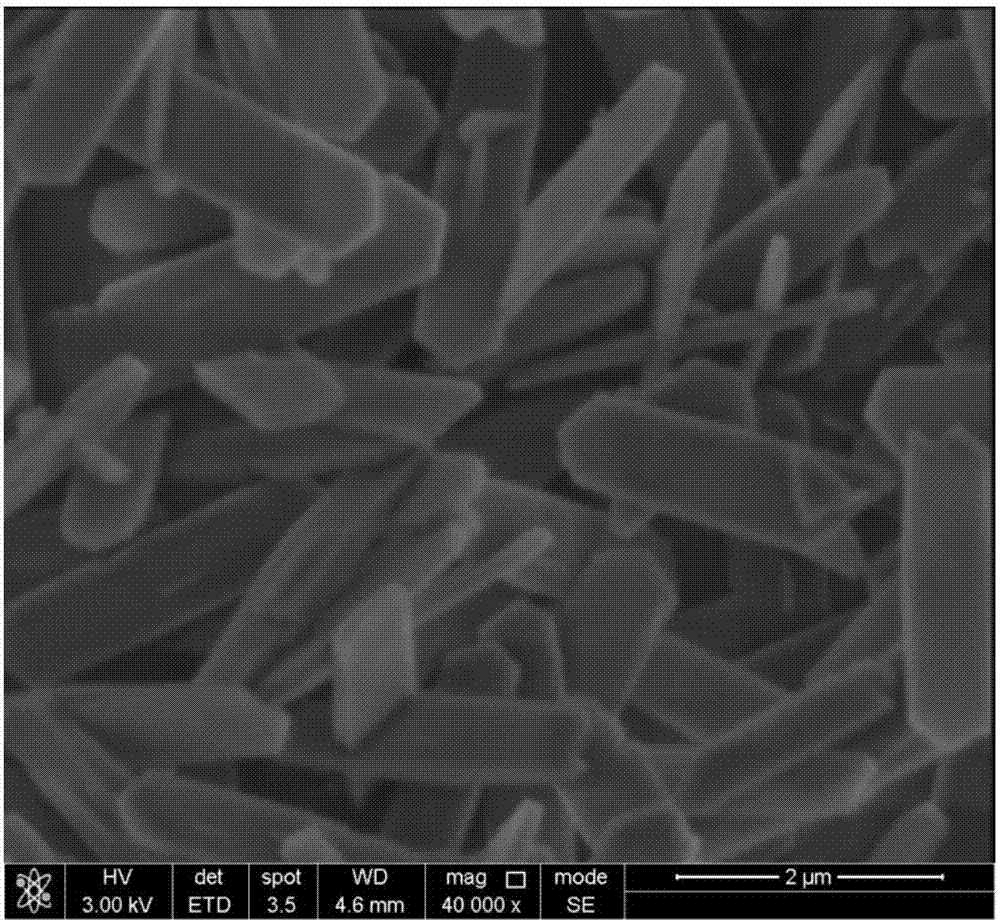

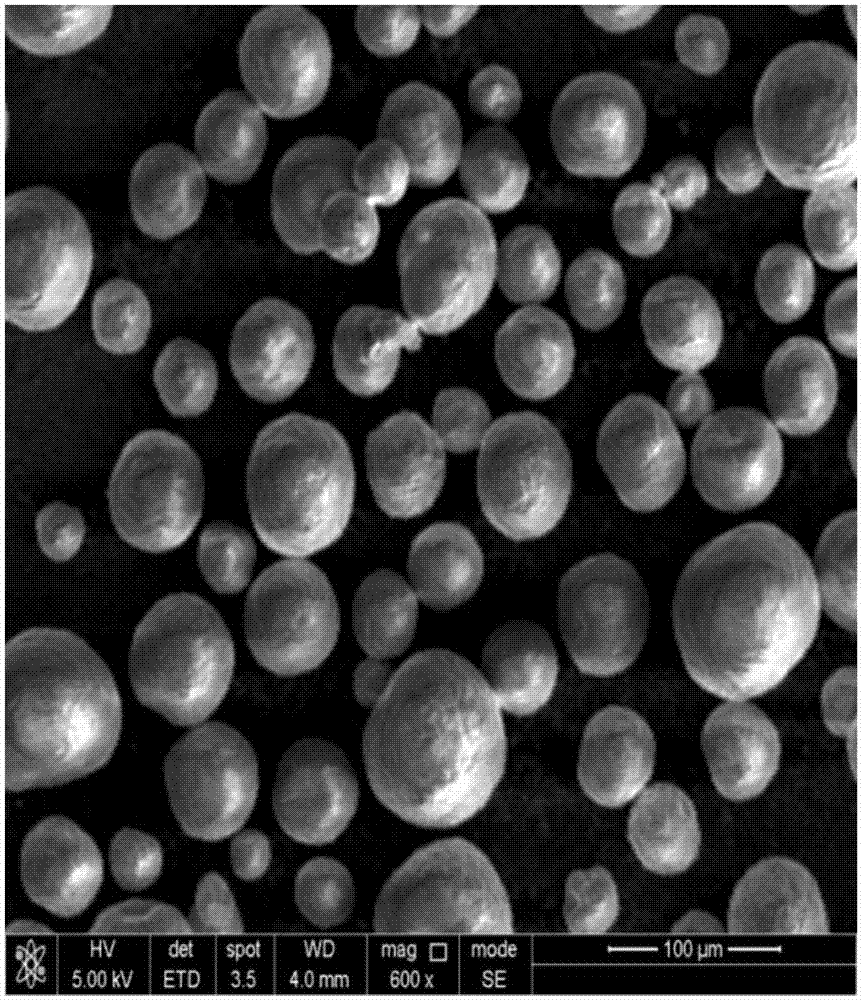

Catalyst for conversion of organic oxy-compound into olefin molecular sieve and its preparation method and method for preparing olefin from organic oxy-compound

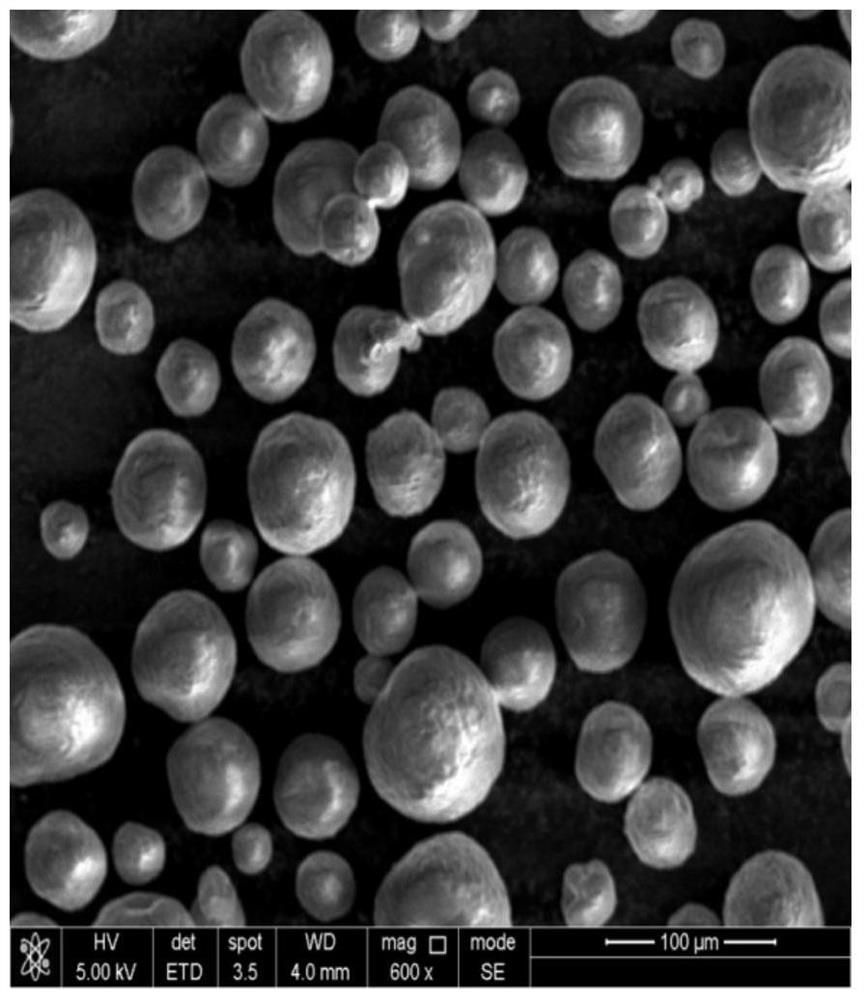

ActiveCN107511167AFacilitated DiffusionReduce secondary reactionsMolecular sieve catalystsHydrocarbon from oxygen organic compoundsFluidized bedSlurry

The invention relates to the field of conversion of an organic oxy-compound into an olefin catalyst. The invention discloses a catalyst for conversion of an organic oxy-compound into an olefin molecular sieve, a preparation method of the catalyst and a method for preparing an olefin from an organic oxy-compound. The preparation method of the catalyst comprises mixing a first binder and an acid to obtain first binder sol, mixing a second binder and the first binder sol to obtain mixed binder sol, mixing a high-silicon ZSM-5 molecular sieve, the mixed binder sol and a carrier, carrying out aging treatment and orderly carrying out spray-drying formation and roasting on the slurry to obtain the catalyst for conversion of an organic oxy-compound into an olefin molecular sieve. The invention also relates to the catalyst for conversion of an organic oxy-compound into an olefin molecular sieve and the method for preparing an olefin. The catalyst has excellent activity and a long service life, is suitable for a fluidized bed reactor and can remarkably improve the selectivity of light olefins in the reaction of preparation of olefins from organic oxy-compounds.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

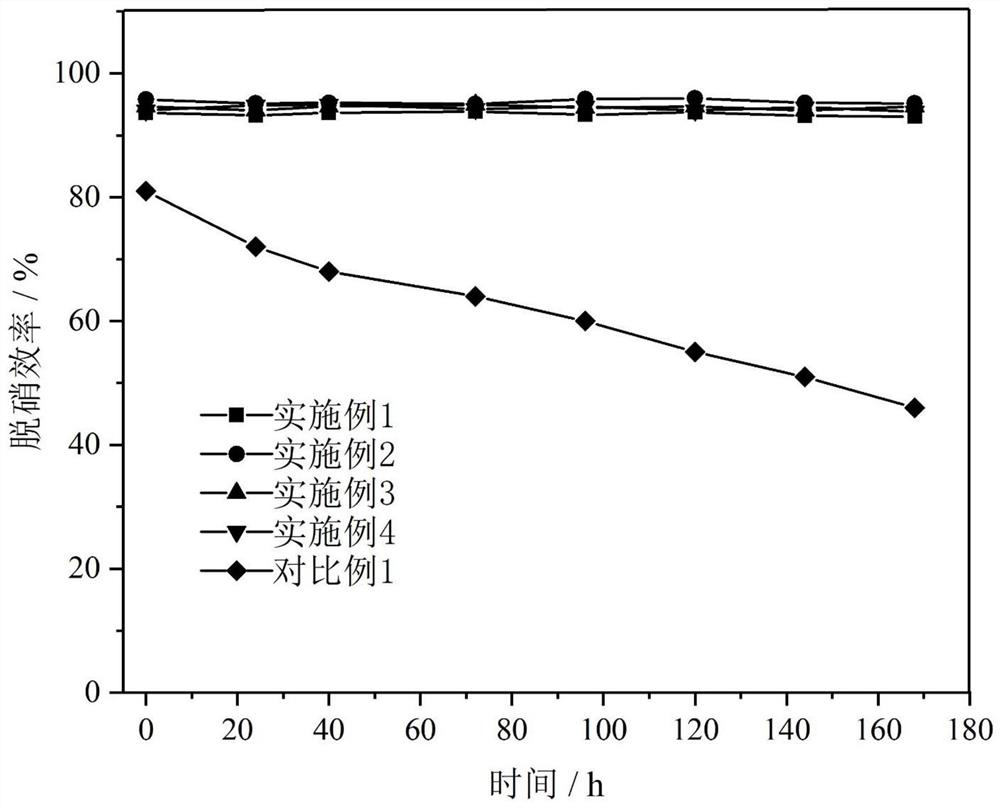

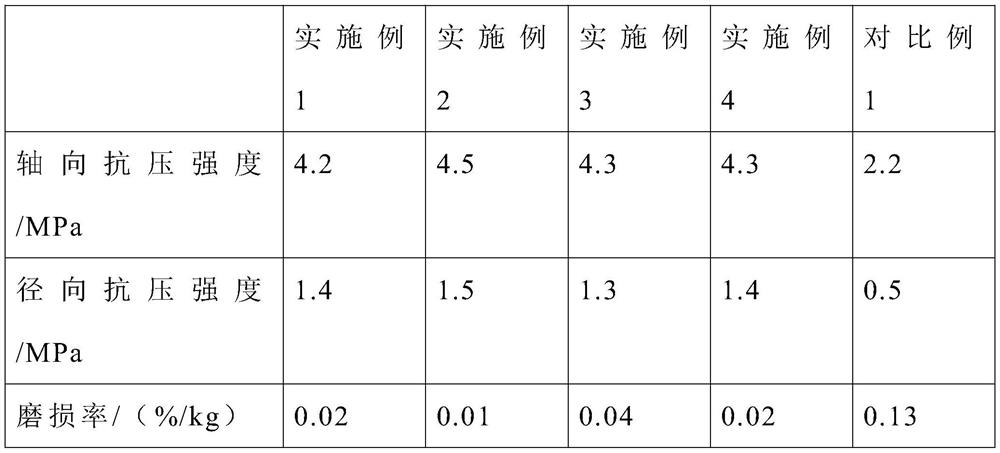

High-strength honeycomb type low-temperature SCR denitration catalyst and preparation method thereof

PendingCN112973668AIncrease the lengthHigh compressive strengthHeterogenous catalyst chemical elementsDispersed particle separationCellulosePtru catalyst

The invention relates to a high-strength honeycomb type low-temperature SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of environment protection and denitration catalysts. The preparation method comprises the following steps: mixing an aluminum oxide and titanium dioxide carrier, an active component solution, an auxiliary agent solution, glass fiber filaments, pseudo-boehmite, kaolin, carboxymethylcellulose, polyacrylamide, polyoxyethylene and glycerol, adding a nitric acid solution, aging, molding by a vertical hydraulic extruder, and finally drying and roasting to obtain the high-strength honeycomb type low-temperature SCR denitration catalyst. The obtained honeycomb type low-temperature catalyst has very strong mechanical property, low-temperature activity and sulfur poisoning resistance, and the removal rate of nitrogen oxides is greater than 90% under the flue gas conditions that the temperature is 120-150 DEG C and the SO2 concentration is 4000 mg / m<3>.

Owner:华电光大(辽阳)节能环保技术有限公司

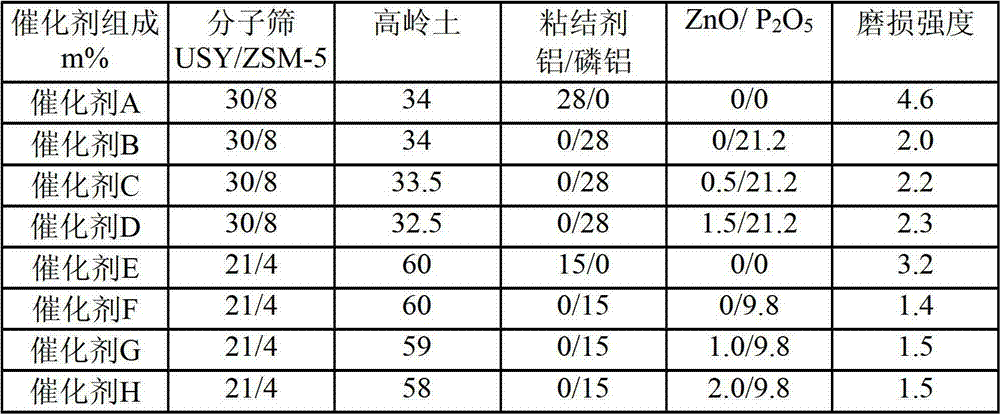

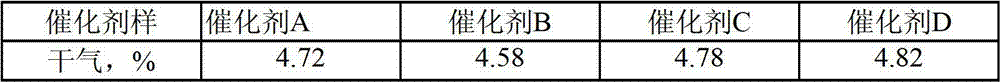

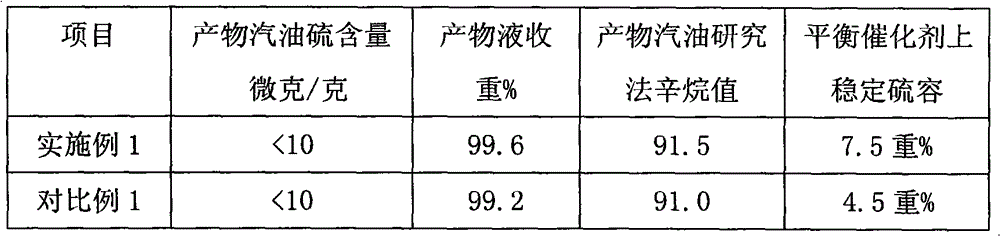

Catalytic cracking catalyst and preparation method thereof

ActiveCN102974386BHigh wear strengthImprove adhesionCatalytic crackingMolecular sieve catalystsAdhesiveGasoline

Owner:山东迅达化工集团有限公司

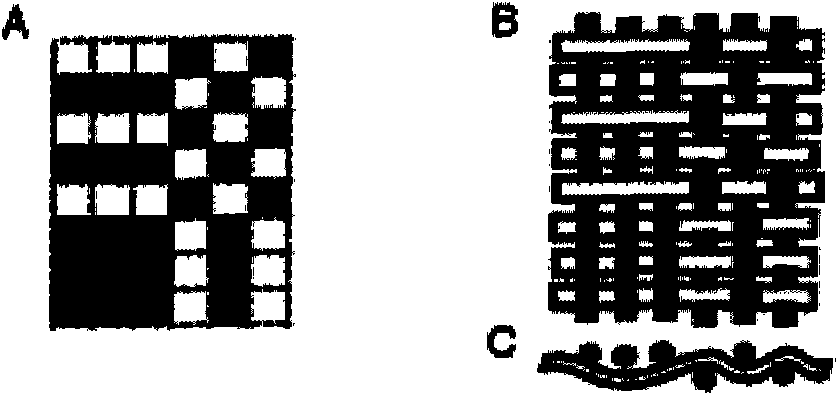

Thin woven fabric

InactiveCN102016144AHigh tear strengthHigh wear strengthFibre typesProtective fabricsSynthetic fiberWoven fabric

Disclosed is a thin woven fabric wherein thermoplastic synthetic fibers of fineness from 5 to 30 dtex are disposed in at least some of the warp and weft threads of a woven fabric and the number of intersections of the warp and weft threads of said woven fabric is from 23 000 to 70 000 / 2.54 cm2. Said woven fabric in the thin woven fabric is subjected to a silicon resin treatment.

Owner:ASAHI KASEI FIBERS CORPORATION

Carbon monoxide combustion catalyst and a process of preparation thereof

ActiveUS20120157293A1Improved combustion levelHigh wear strengthCatalytic crackingMolecular sieve catalystsCombustionFluidized bed

A carbon monoxide combustion catalyst and a method of making the catalyst used in fluid bed catalytic cracking process. The catalyst can contain metals and other composites which promote oxidation of carbon monoxide to carbon dioxide during regeneration of spent FCC catalyst.

Owner:BHARAT PETROLEUM CORP LTD +1

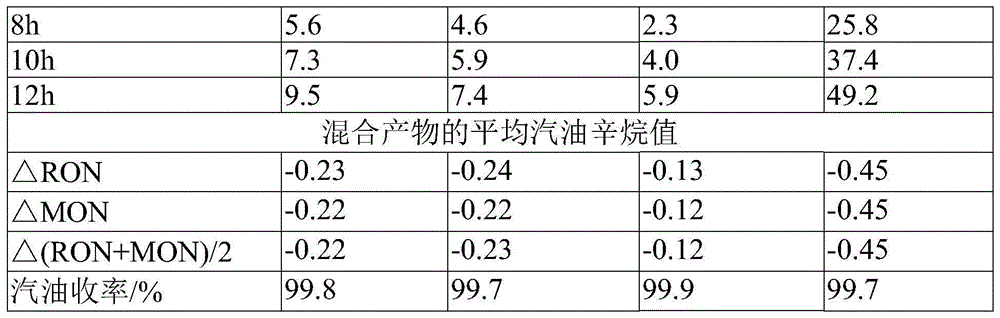

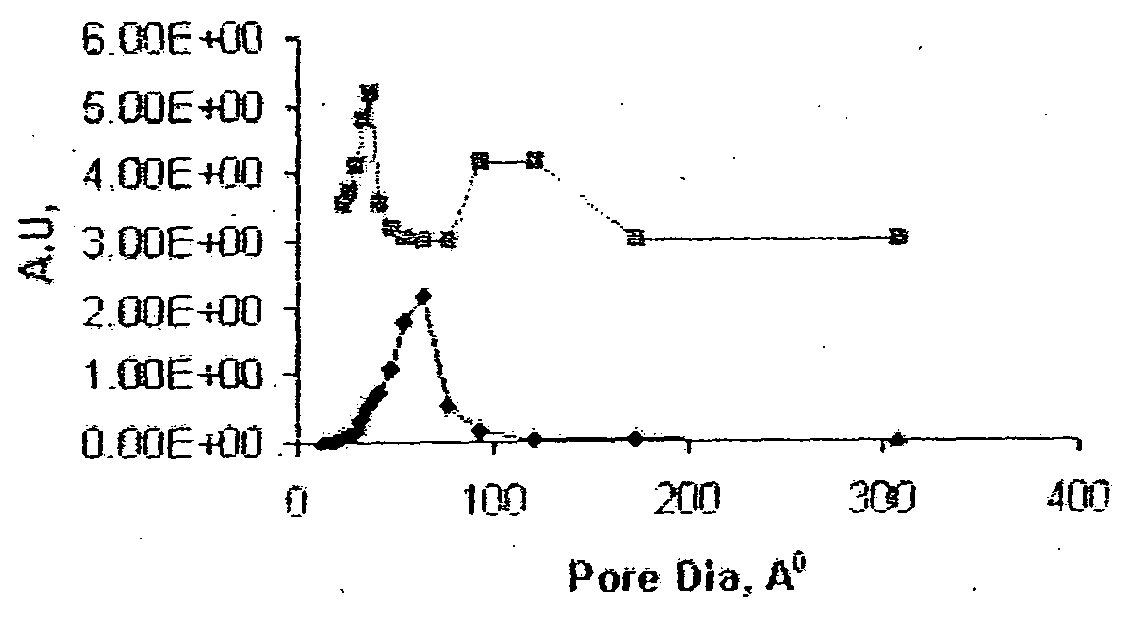

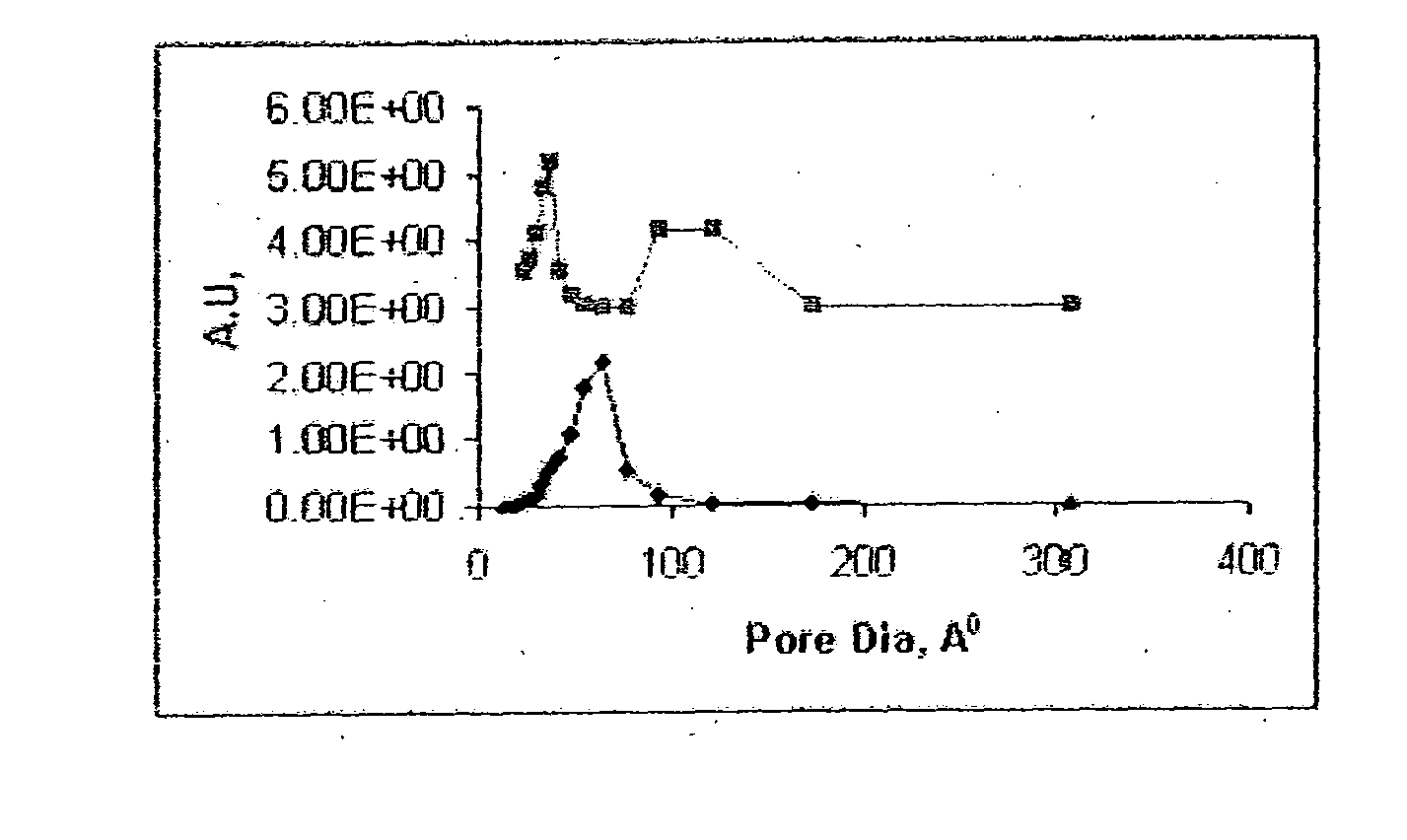

Preparation method of gasoline desulfurization microsphere catalyst

InactiveCN102744073ALess octane lossHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNickel saltMicrosphere

The invention relates to a preparation method of a gasoline desulfurization microsphere catalyst. The method is characterized by: adding activated zinc oxide accounting for 30-60wt% of the total dry basis of the catalyst, expanded perlite powder and / or diatomite accounting for 5-20wt% of total dry basis, and a nickel salt, in terms of nickel oxide, accounting for 10-30wt% of the total dry basis into chemical water for mixing and beating, and raising the temperature to 60-90DEG C, at the same time continuously adding a sodium aluminate solution and an aluminum sulfate solution with a concentration of 1-20 wt%, adjusting and controlling the flow ratio of the two solutions to maintain the pH of the whole slurry at 7.5-9.5; and with the total amount of alumina in the sodium aluminate and aluminum sulfate accounting for 5-20wt% of the total dry basis of the catalyst, atomizing the uniformly mixed material slurry into microspheres with an average particle diameter of 50-80 microns, then conducting washing with chemical water till sodium oxide is less than 1.0wt%, and after drying, carrying out roasting at a temperature of 450-650DEG C for 0.5-4 hours. The prepared catalyst has a pore volume of 0.1-0.4 ml / g, and is characterized by good strength, high activity, large sulfur capacity, as well as low loss of liquid yield and gasoline octane number in a gasoline desulfurization reaction.

Owner:崔超

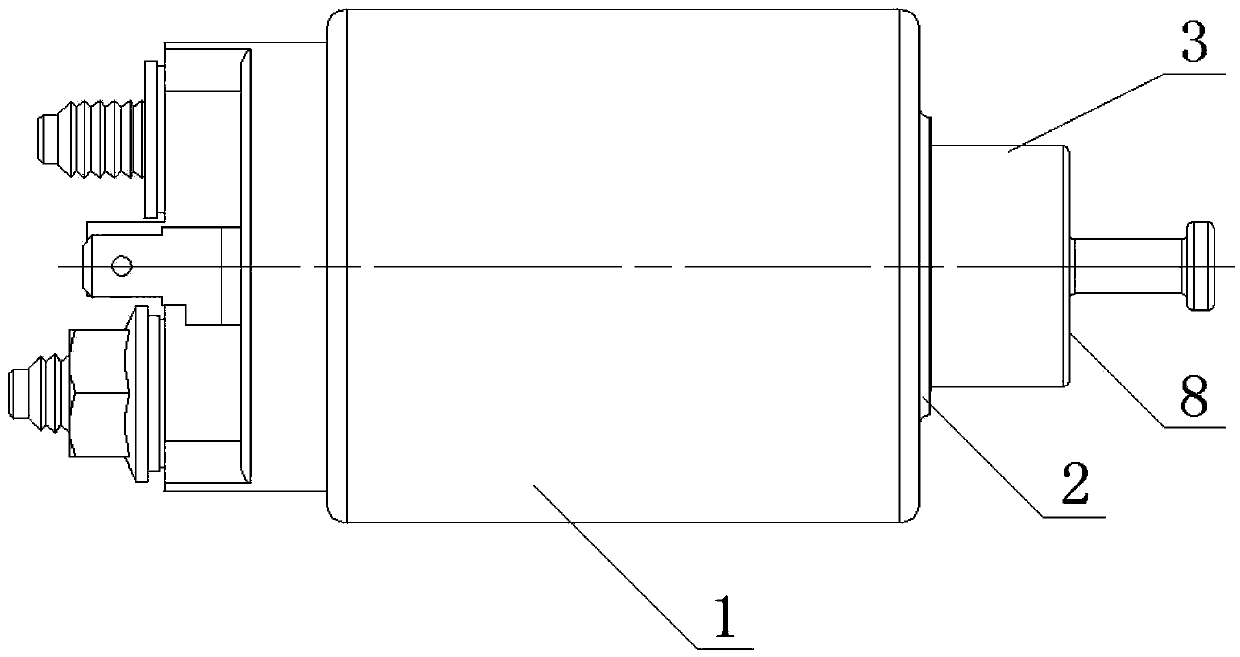

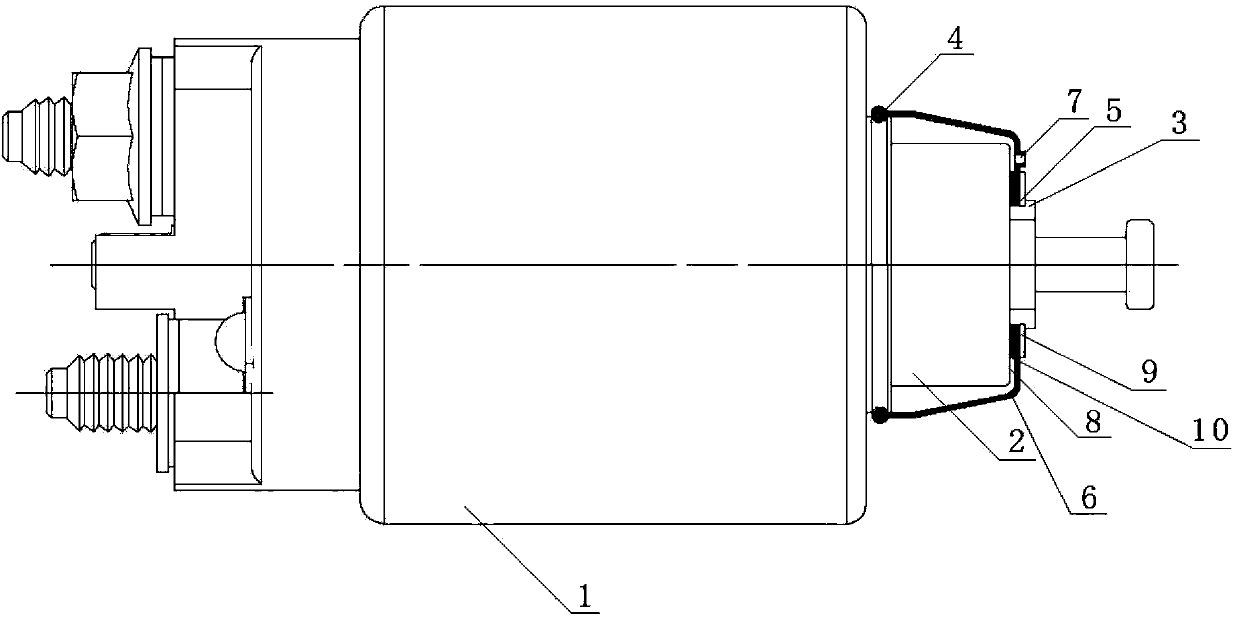

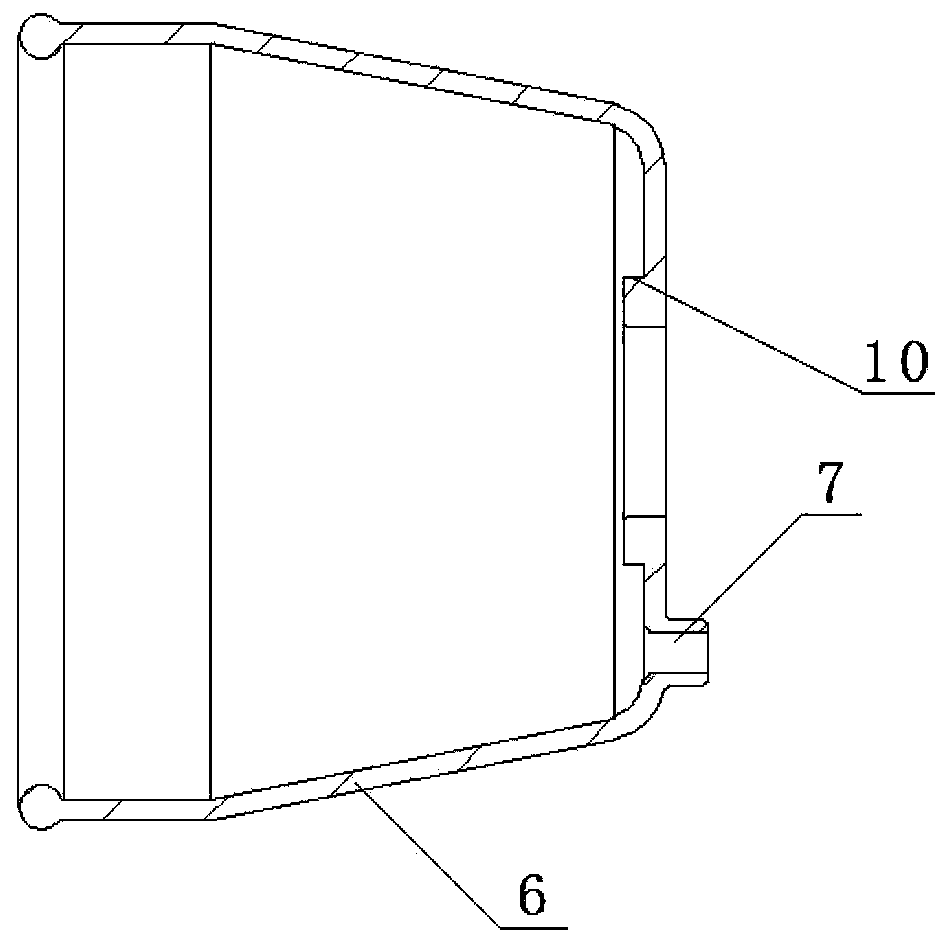

Electromagnetic switch protective structure and mounting method thereof

InactiveCN103426685AIncreasing the thicknessSmall amount of compressionElectromagnetic relay detailsMechanical engineering

Owner:芜湖杰诺瑞汽车电器系统有限公司

Thin woven fabric

InactiveCN103147204AHigh tear strengthHigh wear strengthFibre typesProtective fabricsEngineeringSynthetic fiber

Owner:ASAHI KASEI KK

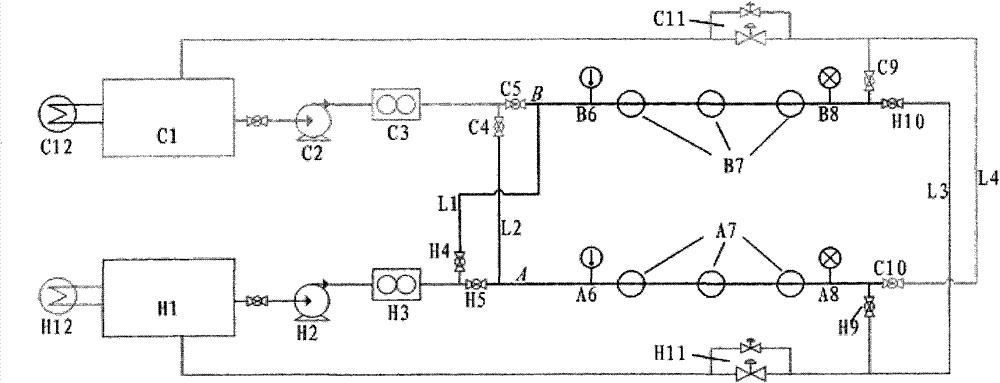

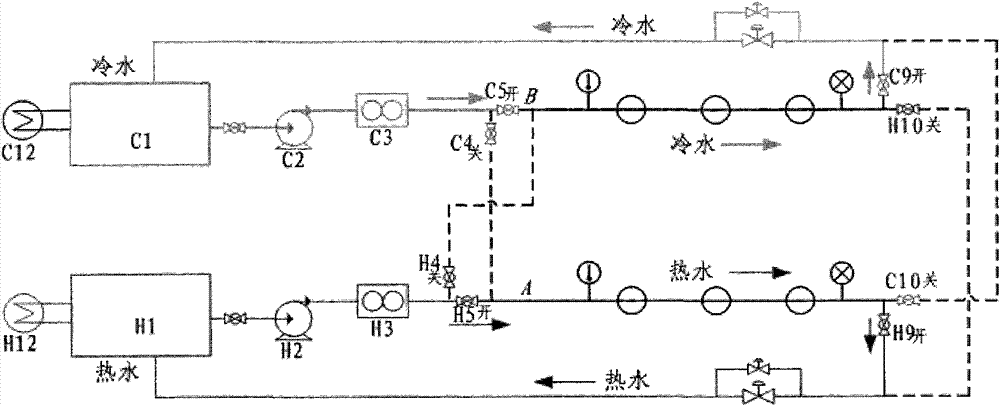

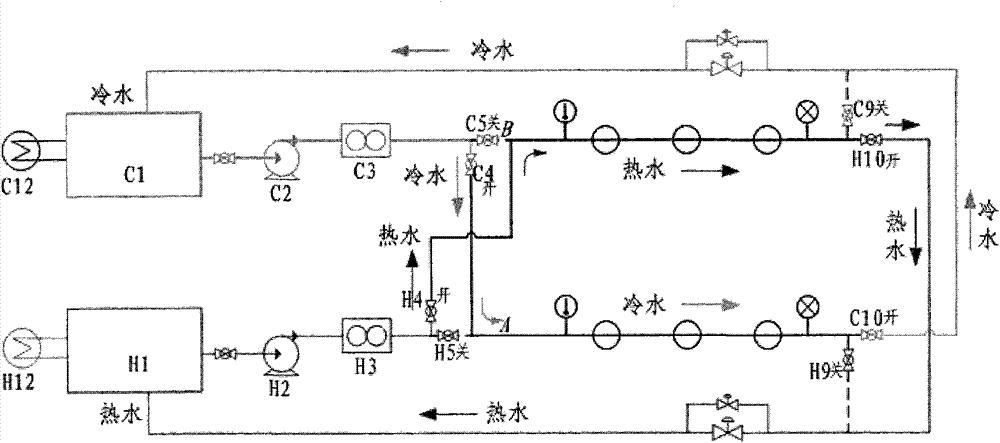

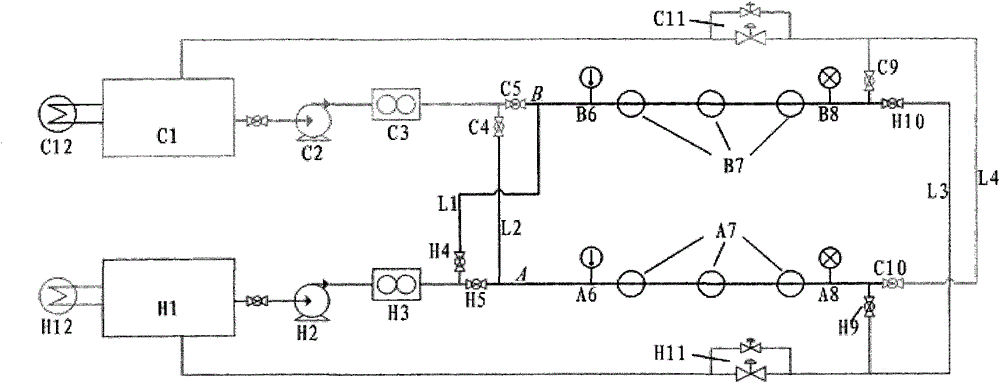

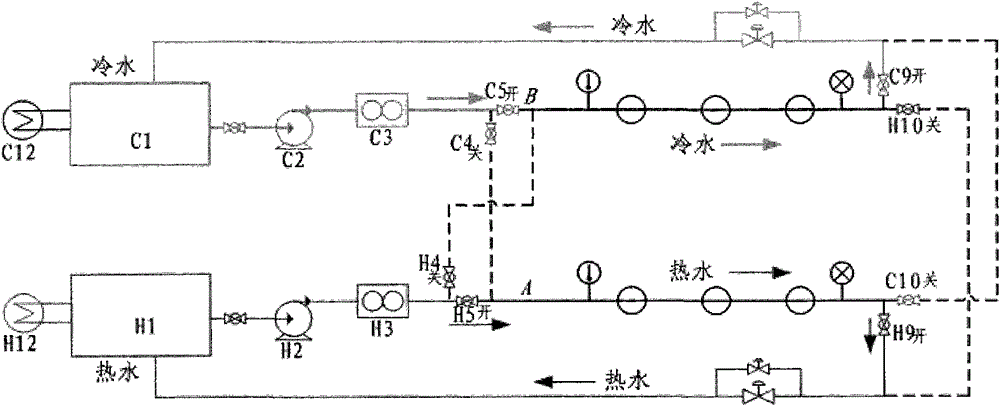

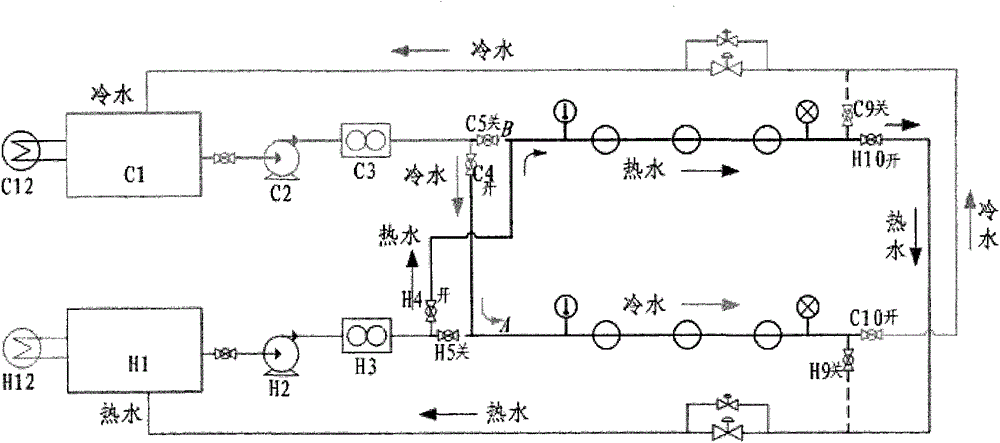

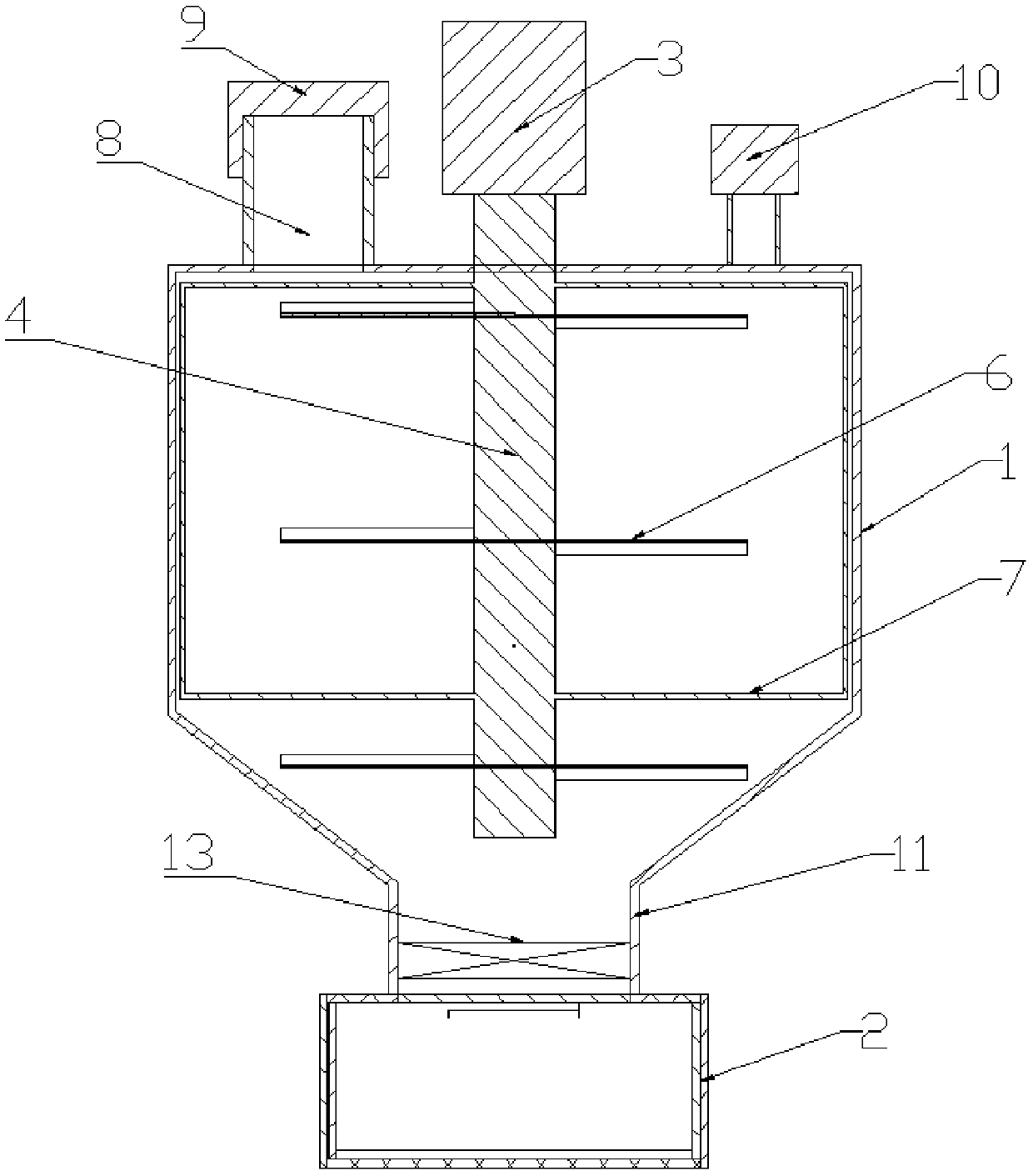

Alternation type flow instrument durability experimental facility

ActiveCN103884404AQuick switchAvoid the Shock of Wear ExperimentsTesting/calibration apparatusEngineeringDependability

The invention discloses an alternation type flow instrument durability experimental facility. The alternation type flow instrument durability experimental facility comprises at least one water tank, at least one water pump matched with the at least one water tank, a first experimental pipeline and a second experimental pipeline, wherein a plurality of instruments to be tested are arranged in the first experimental pipeline, and a plurality of instruments to be tested are arranged in the second experimental pipeline. According to the alternation type flow instrument durability experimental facility, the design that two water supply systems and the two experimental pipelines are combined is adopted; during a whole durability test, the two sets of water supply systems are kept to be in a stable operating condition and are prevented from being impacted by an abrasion test, the reliability of the test is guaranteed, and the service life of equipment is guaranteed; meanwhile, the instruments to be tested can be converted to be in different operating states rapidly, high abrasion strength is achieved, and both the temperature alternation mode and the flow alternation mode are achieved.

Owner:NAT INST OF METROLOGY CHINA +1

An Alternating Flow Meter Durability Experimental Device

ActiveCN103884404BQuick switchAvoid the Shock of Wear ExperimentsTesting/calibration apparatusEngineeringDependability

The invention discloses an alternation type flow instrument durability experimental facility. The alternation type flow instrument durability experimental facility comprises at least one water tank, at least one water pump matched with the at least one water tank, a first experimental pipeline and a second experimental pipeline, wherein a plurality of instruments to be tested are arranged in the first experimental pipeline, and a plurality of instruments to be tested are arranged in the second experimental pipeline. According to the alternation type flow instrument durability experimental facility, the design that two water supply systems and the two experimental pipelines are combined is adopted; during a whole durability test, the two sets of water supply systems are kept to be in a stable operating condition and are prevented from being impacted by an abrasion test, the reliability of the test is guaranteed, and the service life of equipment is guaranteed; meanwhile, the instruments to be tested can be converted to be in different operating states rapidly, high abrasion strength is achieved, and both the temperature alternation mode and the flow alternation mode are achieved.

Owner:NAT INST OF METROLOGY CHINA +1

NOX reduction catalyst

PendingCN113507984AImprove wear resistanceDecreased denitrification rateGas treatmentEmission preventionPtru catalystNitrogen oxides

Owner:MITSUBISHI HEAVY IND LTD

Preparation method of gasoline desulfurization microsphere catalyst

InactiveCN102744073BLess octane lossHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNickel saltMicrosphere

The invention relates to a preparation method of a gasoline desulfurization microsphere catalyst. The method is characterized by: adding activated zinc oxide accounting for 30-60wt% of the total dry basis of the catalyst, expanded perlite powder and / or diatomite accounting for 5-20wt% of total dry basis, and a nickel salt, in terms of nickel oxide, accounting for 10-30wt% of the total dry basis into chemical water for mixing and beating, and raising the temperature to 60-90DEG C, at the same time continuously adding a sodium aluminate solution and an aluminum sulfate solution with a concentration of 1-20 wt%, adjusting and controlling the flow ratio of the two solutions to maintain the pH of the whole slurry at 7.5-9.5; and with the total amount of alumina in the sodium aluminate and aluminum sulfate accounting for 5-20wt% of the total dry basis of the catalyst, atomizing the uniformly mixed material slurry into microspheres with an average particle diameter of 50-80 microns, then conducting washing with chemical water till sodium oxide is less than 1.0wt%, and after drying, carrying out roasting at a temperature of 450-650DEG C for 0.5-4 hours. The prepared catalyst has a pore volume of 0.1-0.4 ml / g, and is characterized by good strength, high activity, large sulfur capacity, as well as low loss of liquid yield and gasoline octane number in a gasoline desulfurization reaction.

Owner:崔超

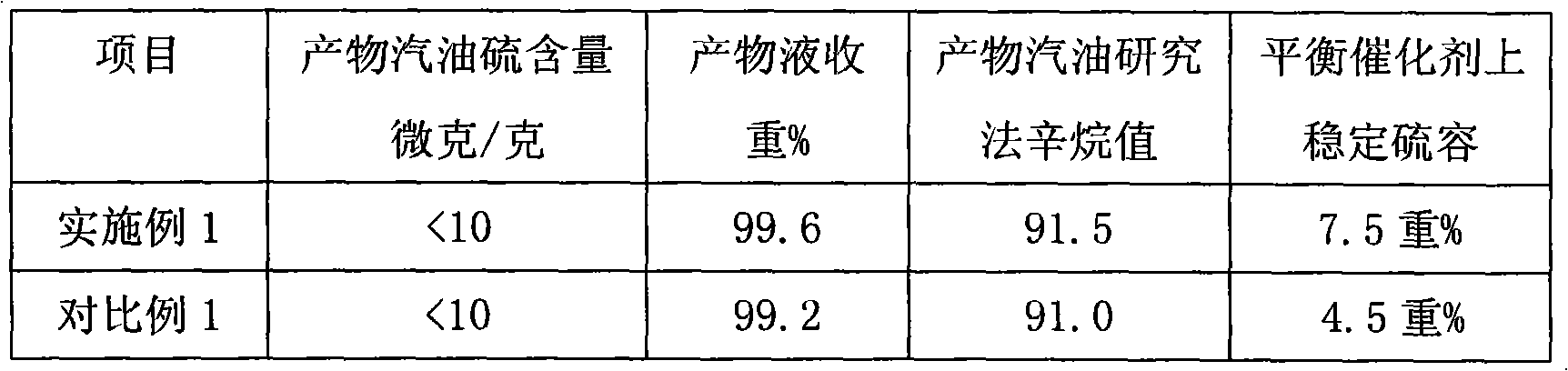

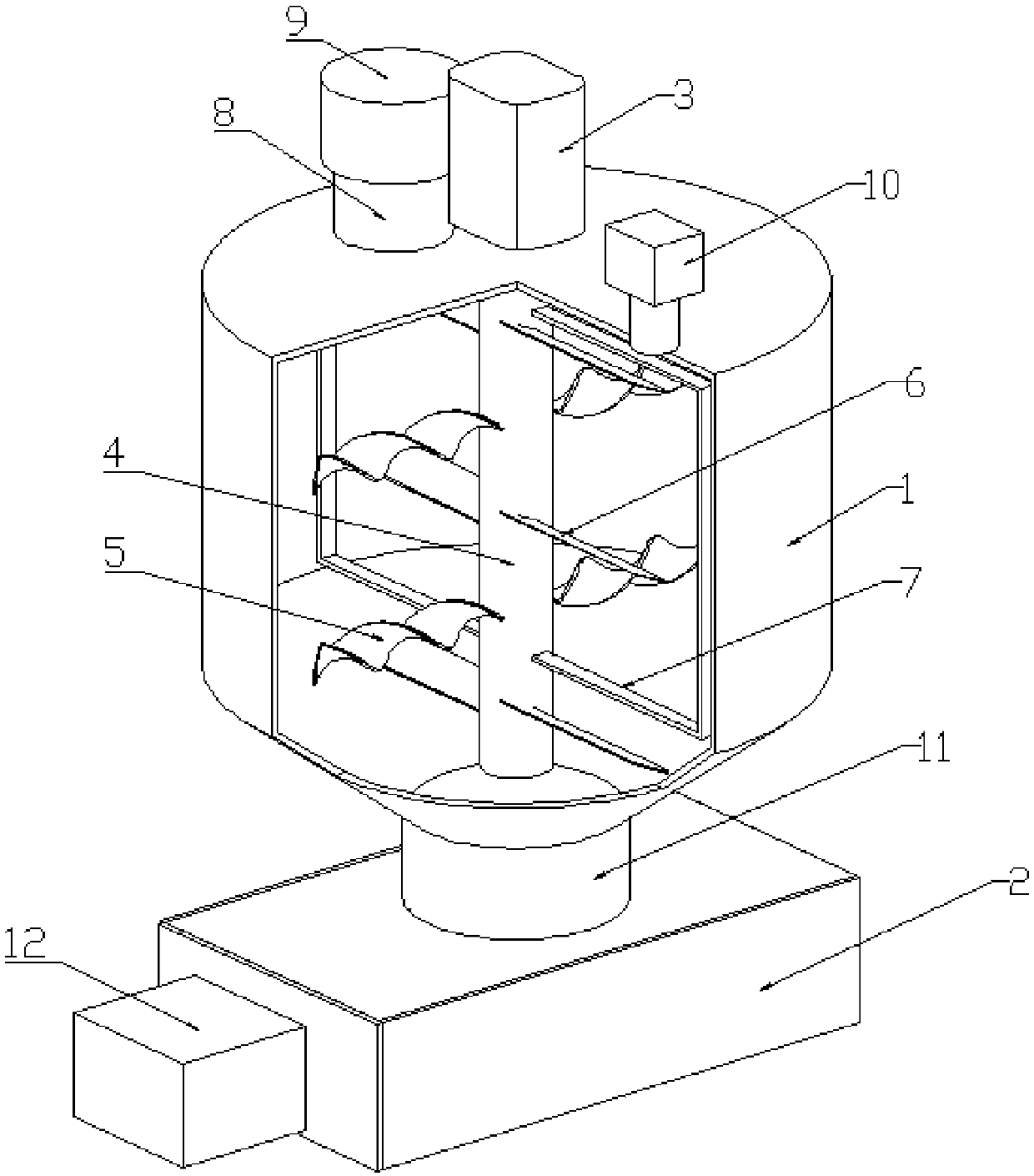

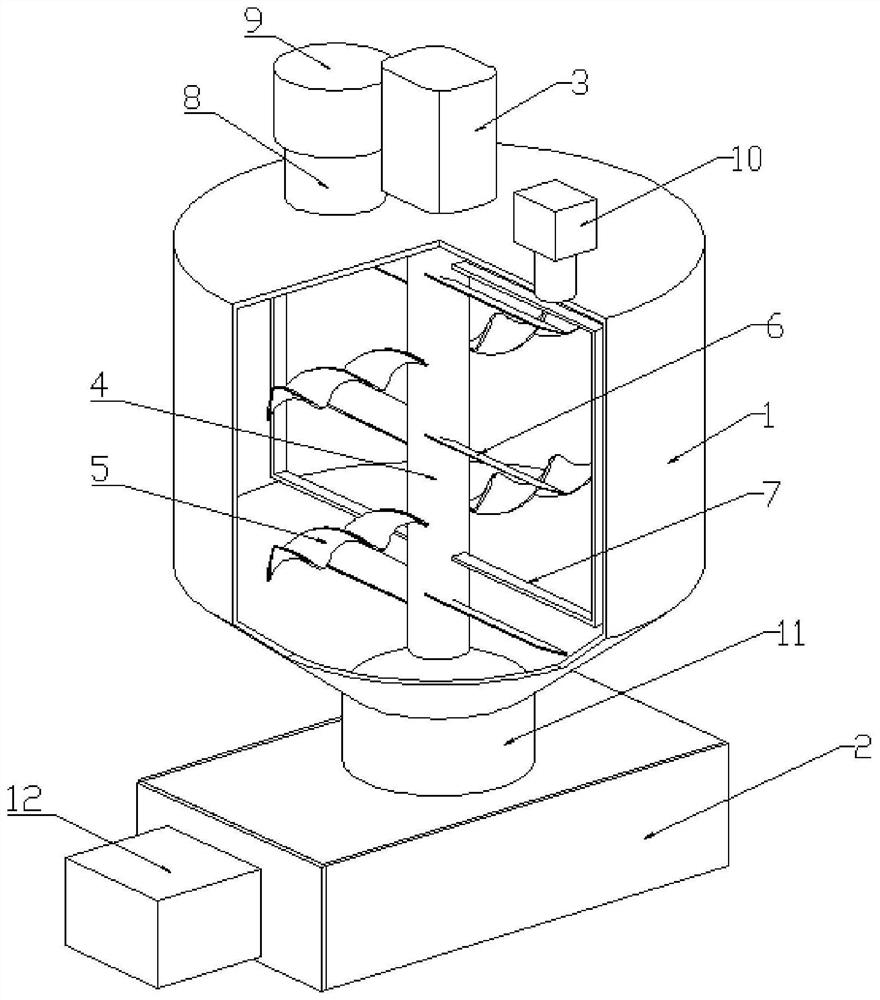

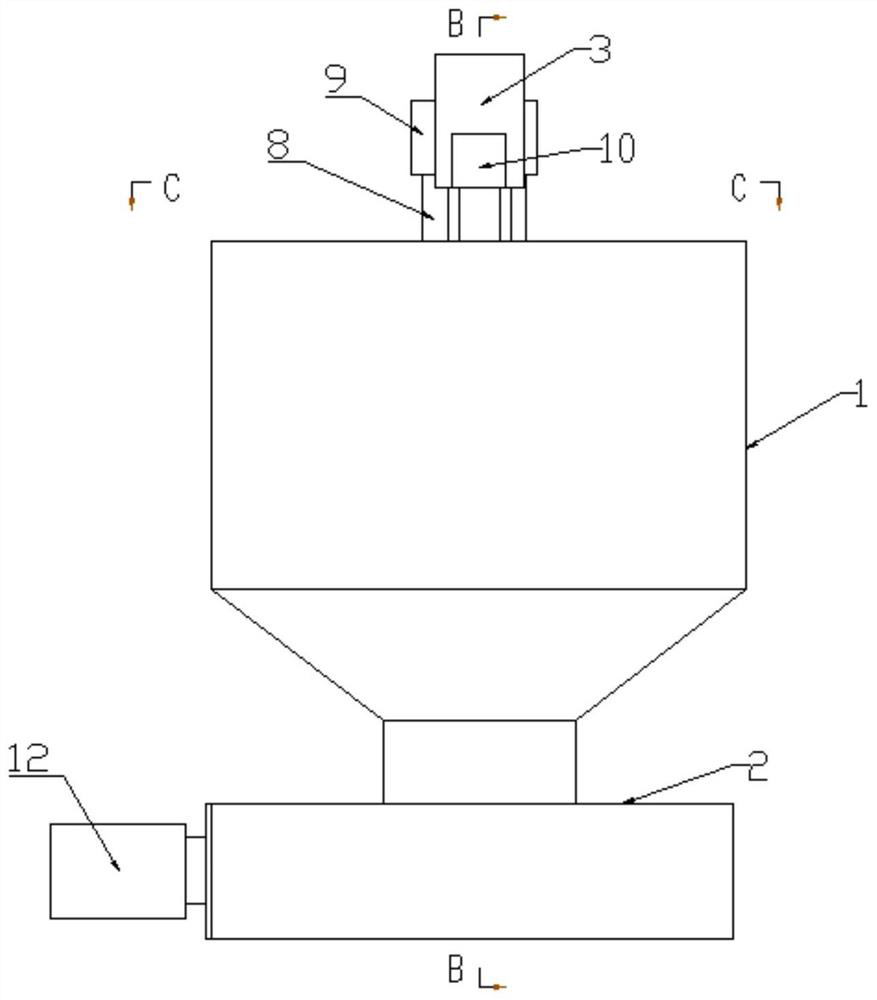

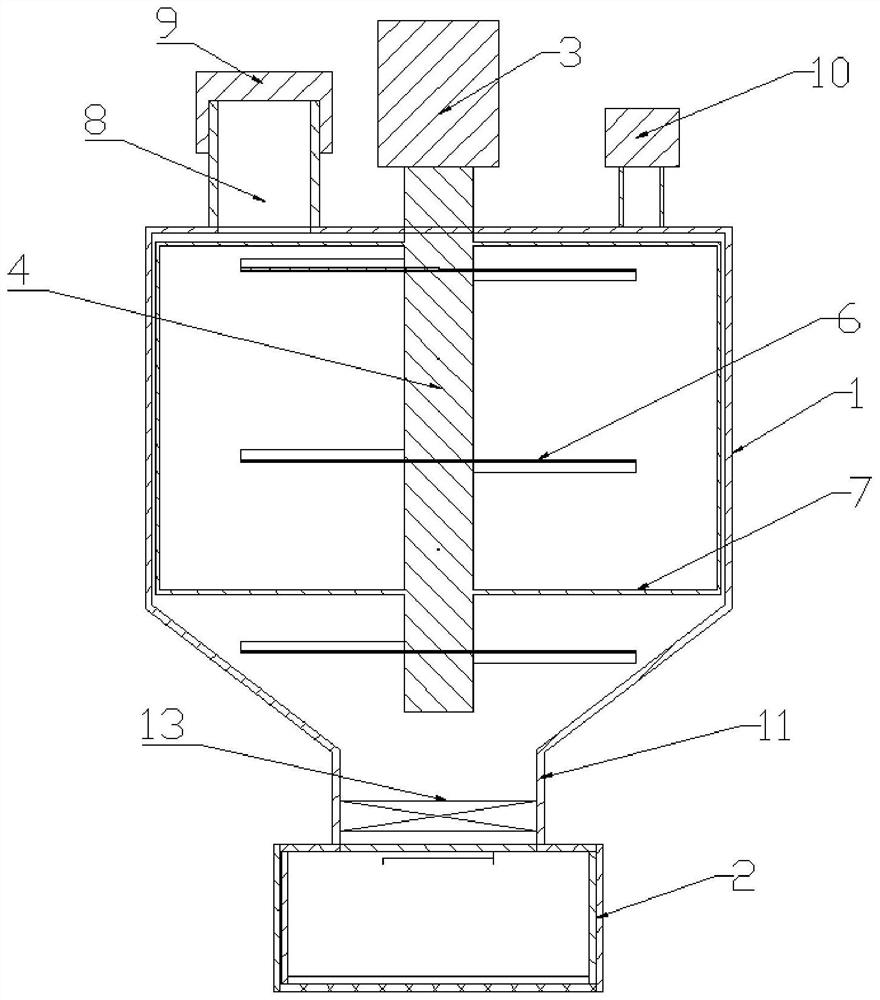

Solid silicon aluminum phosphorus molecular sieve forming method and device

ActiveCN109650404AEasy to pushStir wellMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSlurry

The invention provides a solid silicon aluminum phosphorus molecular sieve forming method and a device. The device comprises a batching kettle and a pusher; the batching kettle is further connected with a vacuum pump; a stirrer is arranged in the batching kettle; the stirrer comprises a rotating shaft vertically arranged in the batching kettle and stirring vanes and a scraper frame arranged on therotating shaft. The side edge of the scraper frame fits with the inner wall of the batching kettle. The pusher is arranged at the discharge port of the batching kettle and is used for pushing materials and converting vertical discharging into horizontal discharging. By the use of the device, materials can be mixed more uniformly, and fewer bubbles are mixed into the slurry. The problem of hollowing after molding of silicon aluminum phosphorus molecules is solved, and the problem that materials are pasted on the kettle wall and pipelines are blocked is effectively alleviated.

Owner:CHINA TIANCHEN ENG +1

A method and device for forming a solid silicon-aluminum-phosphorus molecular sieve

ActiveCN109650404BEasy to pushStir wellMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveMetallurgy

The invention provides a solid silicon aluminum phosphorus molecular sieve forming method and a device. The device comprises a batching kettle and a pusher; the batching kettle is further connected with a vacuum pump; a stirrer is arranged in the batching kettle; the stirrer comprises a rotating shaft vertically arranged in the batching kettle and stirring vanes and a scraper frame arranged on therotating shaft. The side edge of the scraper frame fits with the inner wall of the batching kettle. The pusher is arranged at the discharge port of the batching kettle and is used for pushing materials and converting vertical discharging into horizontal discharging. By the use of the device, materials can be mixed more uniformly, and fewer bubbles are mixed into the slurry. The problem of hollowing after molding of silicon aluminum phosphorus molecules is solved, and the problem that materials are pasted on the kettle wall and pipelines are blocked is effectively alleviated.

Owner:CHINA TIANCHEN ENG +1

Catalyst system for desulfurization of sulfur-containing hydrocarbons, method and device for desulfurization of sulfur-containing hydrocarbons

ActiveCN104549303BGood dispersionConducive to synergyMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMicrosphereSilicon oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

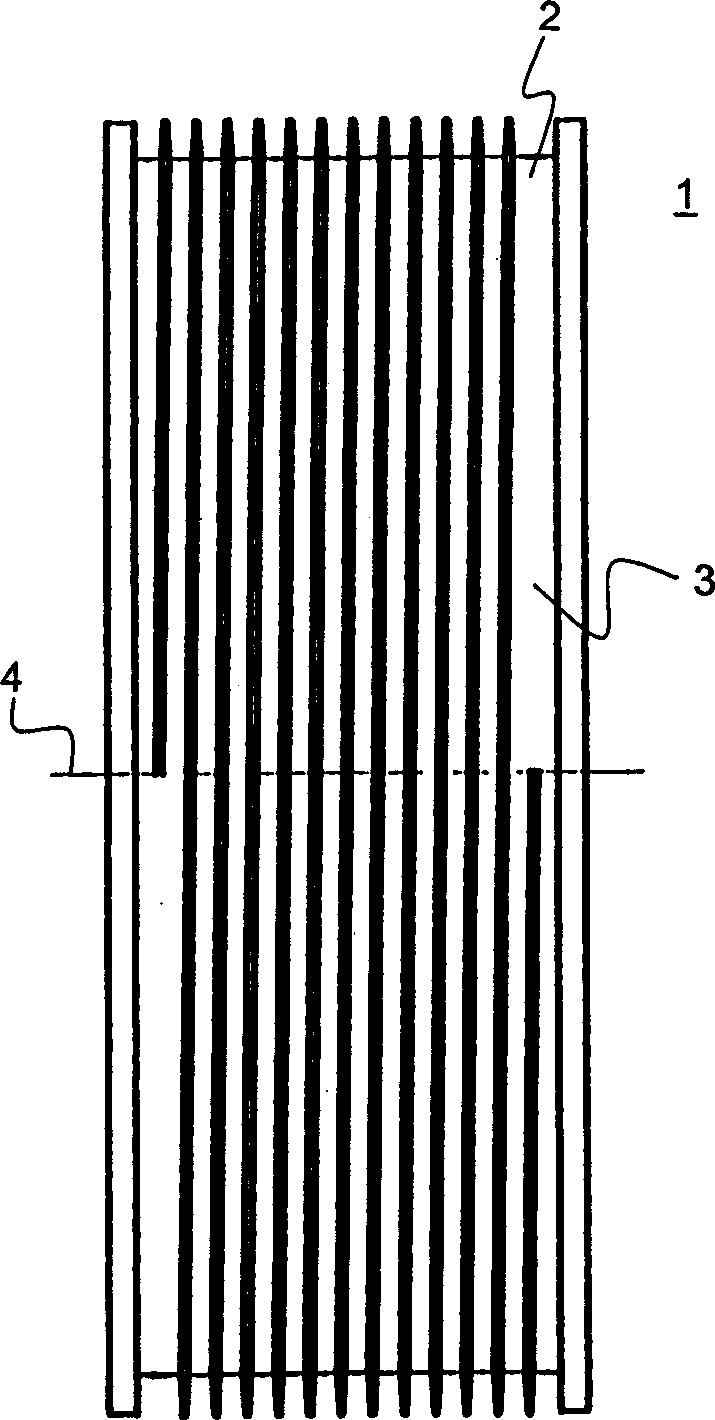

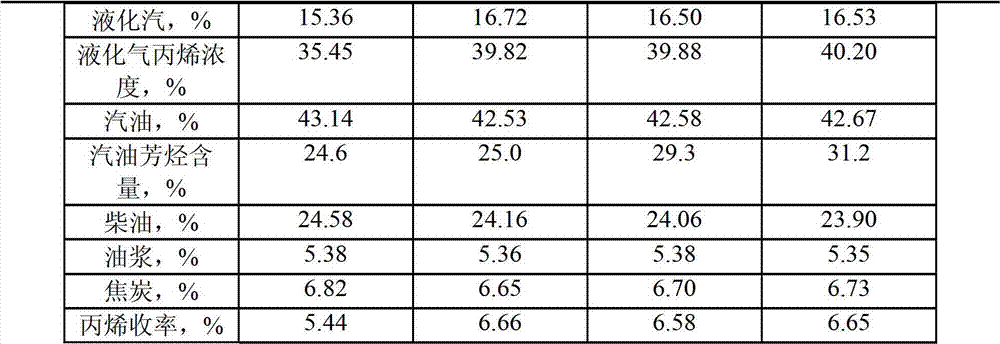

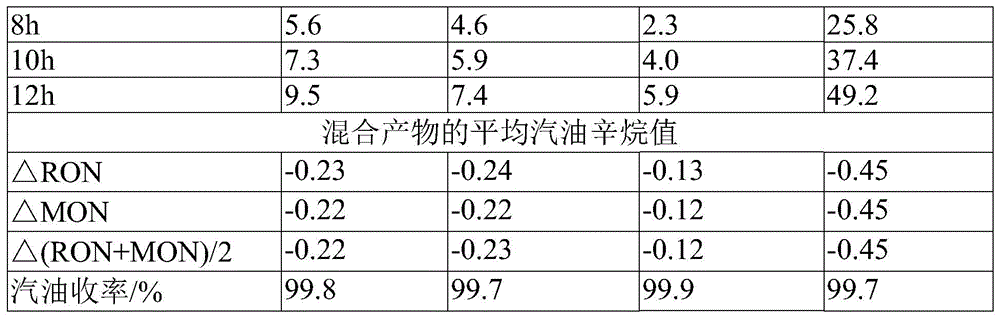

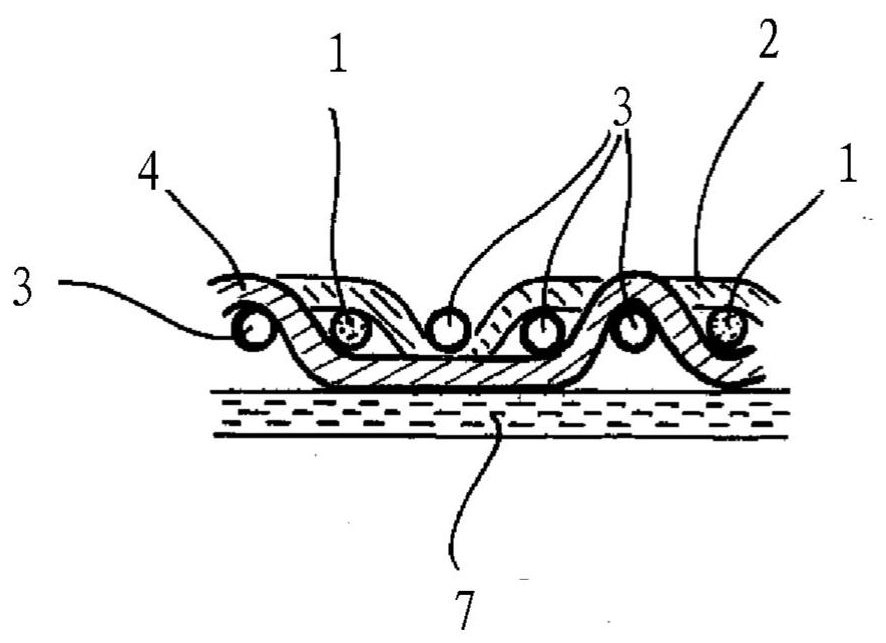

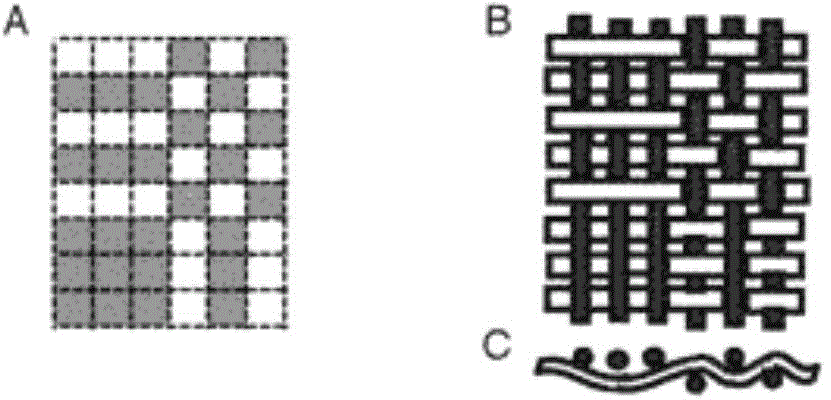

Adhesive tape, in particular wrapping tape

PendingCN111971357AHigh wear strengthCutting strength and impact strengthProtective fabricsInsulated cablesComposite materialEngineering

The subject matter of the invention is an adhesive tape, in particular a wrapping tape for sheathing cables in automobiles. The tape has a fabric backing (1, 3, 2, 4) in the form of a monoweave and anadhesive coating (7) on at least one side of the backing (1, 3, 2, 4). According to the invention, the monoweave is at least three-ply, and abrasion-resistant, non-connected warp threads (1, 3) forman outer layer and an inner layer. An intermediate layer made of weft threads (2, 4) is provided, the bonding points (5) of said layer coinciding with those of the outer layer and not with the bondingpoints (6) of the inner layer.

Owner:CERTOPLAST TECHN KLEBEBANDER

Opening device for spinning machines

InactiveCN1789508BGuaranteed flexibilityReduce riskVacuum evaporation coatingSputtering coatingFiberEngineering

The invention relates to a spinning machine, in particular to an opening device of a free end spinning machine. The opening device is provided with metallic card clothing (3) or ring clothing (11) used for individually separating the fibers of the fed-in fiber strips. The opening device of the invention is characterized in that the metallic card clothing (3) is pre-bent according to the geometricshape of a supporting ring (2), the ring clothing (11) is provided with the required geometric shape of a processed part, the surface of the corresponding processed part is provided with a structure with at least two layers, wherein an outer layer (13) is a hard material layer which is partially or wholly made of extremely hard material component, and arranged on a base layer (12).

Owner:利特英格纺织机械制造股份公司

Selective catalytic reduction flue gas denitration catalyst and production method thereof

ActiveCN101428240BImprove wear resistanceSimple processCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsFlue gasHoneycomb

The invention relates to a gas denitration catalyst, in particular to a honeycomb denitration catalyst based on the selective catalytic reduction (SCR) technique, and a production method thereof. After a drying monomer with the catalyst composition is sawed, the catalyst is prepared through the following steps: (1) one end part of the monomer is put in an aluminum salt water solution with the density being 1.41-1.45kg / L for being impregnated about 5-12 seconds; (2) a blower is used to blow for 15-25 seconds, so as to blow off superfluous hardening liquid on the surface of the impregnated end part of the monomer; and (3) the monomer after being impregnated in the hardening liquid is calcined in a calciner and hardened. Therefore, the production process of the invention is simple and costs little, and the abrasion strength of the catalyst improved.

Owner:CHENGDU DONGFANG KWH ENVIRONMENTAL PROTECTION CATALYSTS

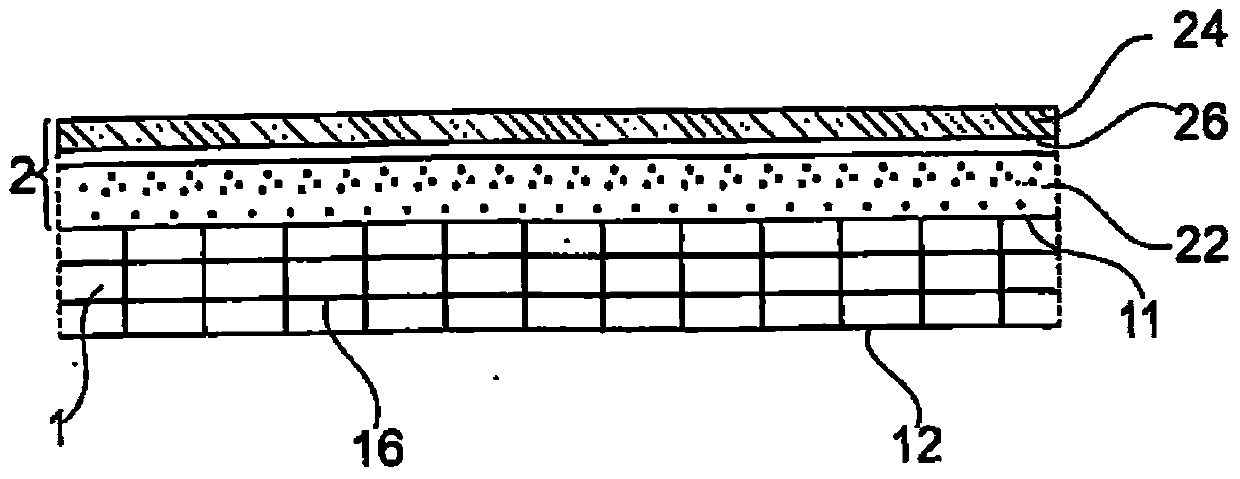

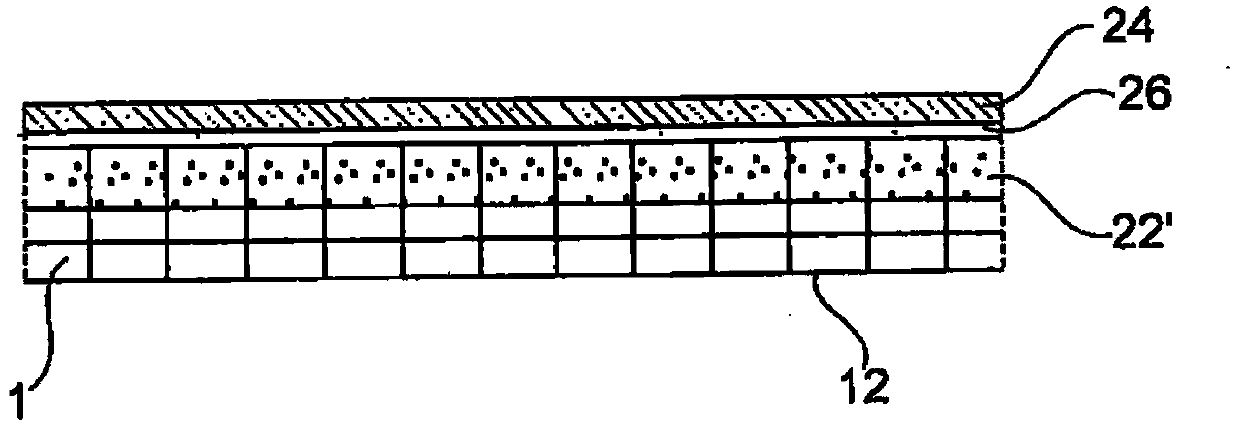

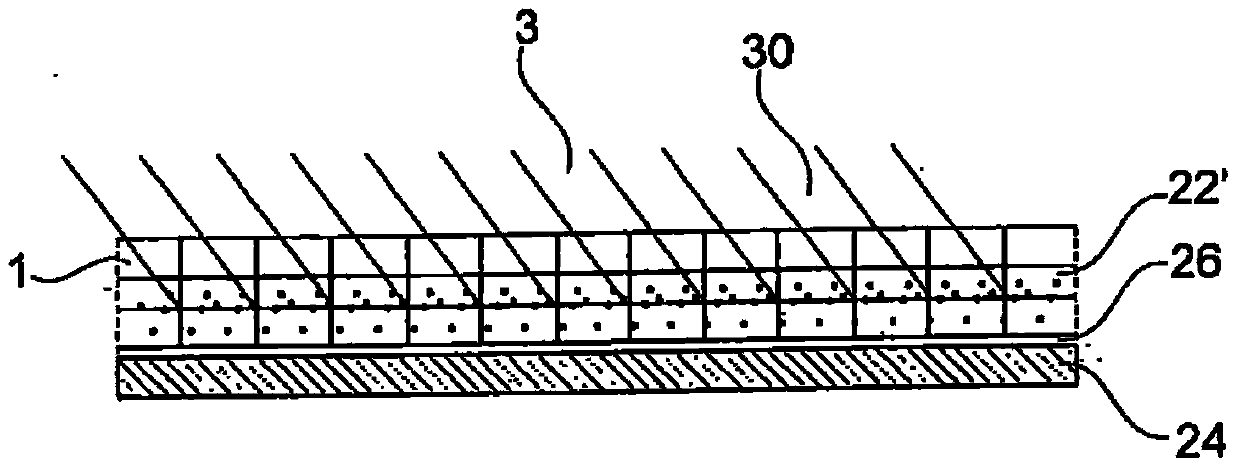

Conveying belt having a multilayer impregnated textile overlay

ActiveCN104011429AReduce coefficient of frictionHigh wear strengthV-beltsDriving beltsEngineeringMelting temperature

The invention relates to a power transmission conveying belt, having a base structure made of polyurethane (30) and a textile overlay (1) and comprising a first coating made of a first thermoplastic material (22') on the surface (11) of the textile overlay (1), which first coating forms an impregnation, has a melting temperature from 80 DEG C to approximately 145 DEG C, and penetrates at least partially into the textile, and comprising a second coating (26) made of a second thermoplastic material on the first coating, which second coating has a higher melting point. The coatings can be applied successively to the textile overlay (1) before the casting of the polyurethane or can be overlaid as individual films or as multi-layer film and applied to the textile overlay by heat and pressure. The coating acts to reduce abrasion and prevents the through passage of the belt polyurethane.

Owner:ARNTZ BET GMBH & CO

Thin woven fabric

InactiveCN104947282AHigh tear strengthHigh wear strengthFibre typesProtective fabricsEngineeringSynthetic fiber

Disclosed is a thin woven fabric wherein thermoplastic synthetic fibers of fineness from 5 to 30 dtex are disposed in at least some of the warp and weft threads of a woven fabric and the number of intersections of the warp and weft threads of said woven fabric is from 23000 to 70000 / 2.54 cm2. Said woven fabric in the thin woven fabric is subjected to a silicone resin treatment.

Owner:ASAHI KASEI KK

Molecular sieve catalyst for preparing olefins from organic oxygen-containing compounds and its preparation method and method for preparing olefins from organic oxygen-containing compounds

ActiveCN107511167BFacilitated DiffusionReduce secondary reactionsMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to the field of catalysts for converting organic oxygen-containing compounds to olefins, and discloses a molecular sieve catalyst for preparing organic oxygen-containing compounds to olefins, a preparation method thereof, and a method for preparing organic oxygen-containing compounds to olefins. The preparation method of the olefin molecular sieve catalyst prepared from organic oxygen-containing compounds: mixing the first binder with an acid to make the first binder peptize; mixing the second binder with the obtained first binder sol to prepare Obtain a mixed binder sol; mix the high-silica ZSM-5 molecular sieve, mixed binder sol, and carrier and perform aging treatment; spray-dry, shape and roast the obtained slurry in sequence; obtain an organic oxygen-containing compound converted into an olefin Catalyst; also relates to a molecular sieve catalyst for preparing olefins from organic oxygen-containing compounds and a method for preparing olefins. The catalyst of the invention has excellent activity and service life, is more suitable for fluidized bed reactors, and can significantly improve the selectivity of low-carbon olefins when used in the reaction of organic oxygen-containing compounds to olefins.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

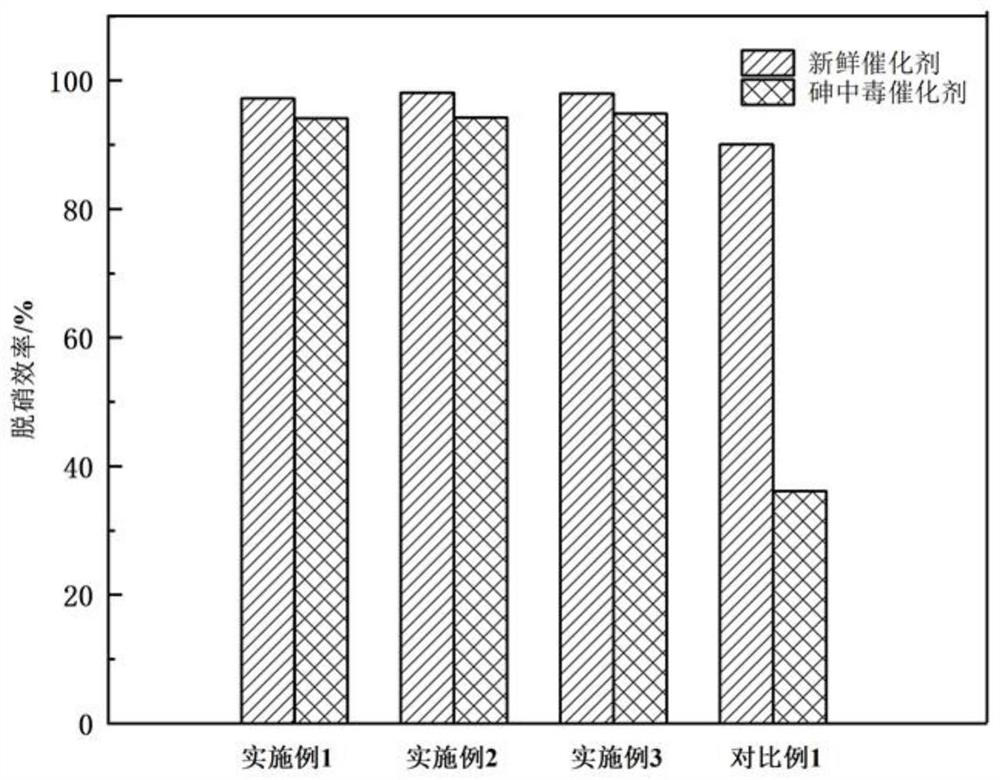

Honeycomb type arsenic poisoning-resistant SCR denitration catalyst and preparation method thereof

PendingCN113522271AIncrease the lengthHigh compressive strengthHeterogenous catalyst chemical elementsDispersed particle separationGlass fiberPtru catalyst

The invention relates to a honeycomb type arsenic poisoning-resistant SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of environment protection and denitration catalysts. The preparation method comprises the following steps: mixing silica powder, a mixed carrier of fumed silica and titanium dioxide, an active component solution, an auxiliary agent solution, glass fiber filaments, pseudo-boehmite, bentonite, hydroxyethyl cellulose, polyacrylamide, polyoxyethylene and sesbania powder, adding a nitric acid solution, aging, and molding by a vertical hydraulic extruder; and finally, drying and roasting to obtain the high-strength honeycomb type arsenic poisoning-resistant SCR denitration catalyst. The obtained honeycomb type arsenic poisoning resisting catalyst has remarkable mechanical performance, denitration activity and arsenic poisoning resisting performance, and the denitration efficiency in high-arsenic flue gas can be stabilized to be 94% or above.

Owner:北京华电光大环境股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com