Preparation method of gasoline desulfurization microsphere catalyst

A catalyst and microsphere technology, which is applied in the field of gasoline desulfurization microsphere catalyst preparation, can solve the problems of large gasoline liquid recovery loss, lower liquid recovery, and lower adsorbent strength, etc., and achieve low octane loss and high hydrogen purity requirements , Hydrogen purity does not require the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

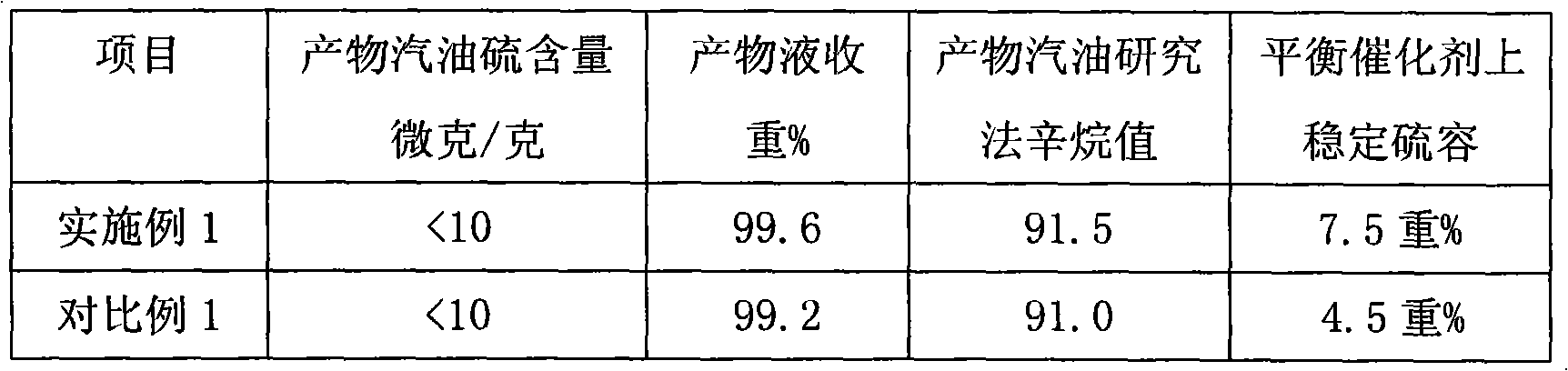

Embodiment 1

[0025] Dissolve 300 grams of nickel nitrate hexahydrate (chemically pure, Beijing Chemical Reagent Company) in 1 liter of water, add 50 grams of expanded perlite powder (industrial product, Xinyuan Bentonite Co., Ltd., Xinyang City, Henan Province, pore volume 1.2 ml / g, solid content 95% by weight) for beating, add 200 grams of basic zinc carbonate (chemically pure, Beijing Chemical Reagent Company) after roasting for 2 hours at 400°C in a muffle furnace to continue beating and be warming up to 65°C, while continuously adding 3% by weight of concentration Sodium aluminate and aluminum sulfate solutions are 1000 grams each, and the pH of the entire slurry is always maintained at 8.0 to 9.0 by adjusting and controlling the flow ratio of the two. Equipment general factory manufacture) beating and homogenizing after 2 hours, microspheres are made in the laboratory with a small spray dryer (LPG-5 type, manufactured by Changzhou Jianda Drying Equipment Co., Ltd.), and the catalyst is...

Embodiment 2

[0027] Dissolve 300 grams of nickel nitrate hexahydrate (same as above) in 1 liter of water, add 50 grams of diatomite (industrial product, Zhejiang Shengzhou Huali Diatomite Products Co., Ltd., pore volume 0.9 ml / g, solid content 95% by weight) Make an oar, add 180 grams of active zinc oxide (industrial products, Hebei Province Gaoyi County Yongchang Zinc Industry Co., Ltd., solid content 90% by weight) continue to make an oar and be warming up to 70 ℃, while continuously adding the sodium aluminate of concentration 5% by weight and Each 600 grams of aluminum sulfate solution, the pH of the whole slurry is always maintained at 8.0 to 9.0 by adjusting and controlling the flow ratio of the two, and the material after the addition is beaten and homogenized by a high-shear mixing emulsifier (same as above) for 3 hours before being tested. Use a small spray dryer (same as above) to make microspheres, wash the catalyst twice with 20 liters of chemical water for 30 minutes each time,...

Embodiment 3

[0029] Dissolve 200 grams of nickel oxalate (chemically pure, Beijing Chemical Reagent Company) in 1 liter of water, add 50 grams of diatomaceous earth (same as above) for beating, add 180 grams of active zinc oxide (same as above) to continue beating and heat up to 68 ° C, while continuously adding 400 grams each of sodium aluminate and aluminum sulfate solution with a concentration of 8% by weight, the pH of the whole slurry is always maintained at 8.0 to 9.0 by adjusting the flow ratio of the two, and the material after the addition is mixed with a high-shear emulsifier (same as above) ) after beating and homogenizing for 2.5 hours, make microspheres on a small spray dryer (same as above) in the laboratory, wash the catalyst 3 times with 15 liters of chemical water, wash for 10 minutes each time, filter and dry at 120°C for 1 hour Then it was calcined in a muffle furnace at 530° C. for 2.5 hours to obtain the gasoline desulfurization microsphere catalyst of Example 3, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com