Opening device for spinning machines

A technology of an opening device and a spinning machine, which is applied in the manufacture of the opening device and the field of the opening device, can solve the problems of unsuitability and the like, and achieve the effect of improving the wear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

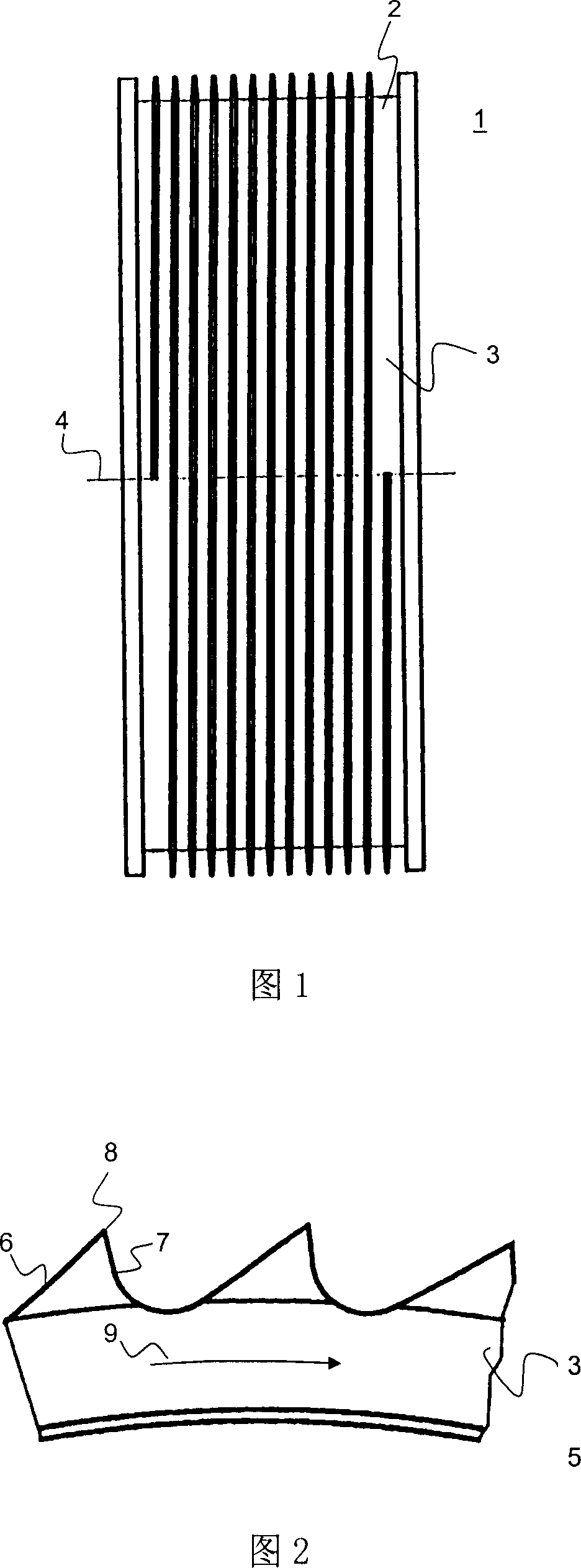

[0034] figure 1 The opening roller 1 according to the invention is shown in side view. A metal card clothing 3 is arranged on a support ring 2 on its radial outer circumference. The metal card clothing is a plurality of coils with a constant inclination arranged axially on the support ring 2 . The opening roller 1 rotates around an axis 4 at a high rotational speed in accordance with normal operating conditions. According to the radial direction of the opening roller 1, the fibers fed, for example, in the form of a fiber sliver are caught when they reach the dial element of the metal card clothing 3 and are released from the fiber sliver. Due to the high speeds, the dial elements are subject to high mechanical wear during continuous operation.

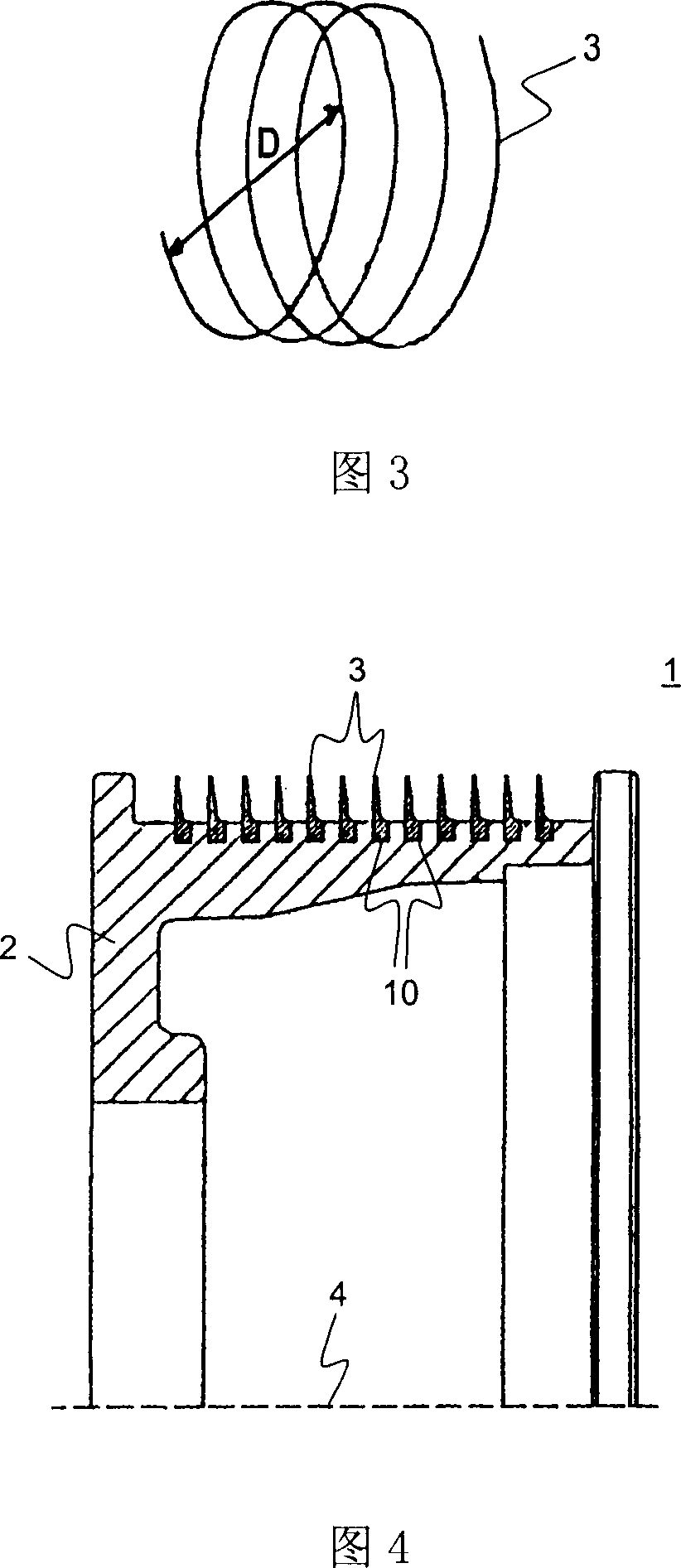

[0035] figure 2 A section of metal clothing 3 is shown in side view. The metallic card clothing 3 has a stitch area 5 for fastening to the support ring 2 . In particular, the shape of the stitches used should match the shape of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com