Conveying belt having a multilayer impregnated textile overlay

A technology for conveyor belts and covering layers, applied to transmission belts, waist belts, V-shaped belts, etc., can solve problems such as hindering sliding improvement, and achieve the effect of reducing friction and high wear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

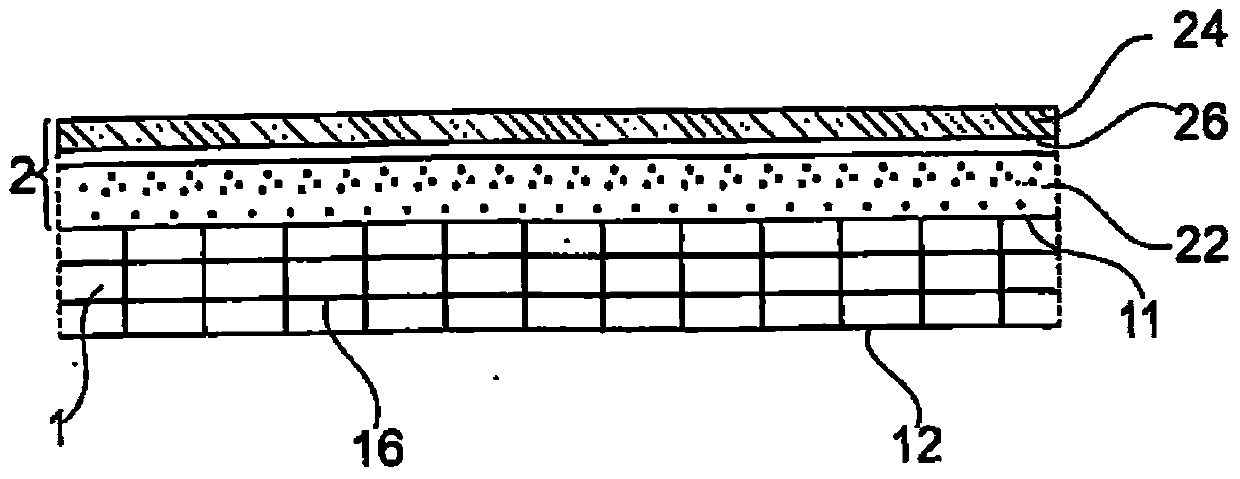

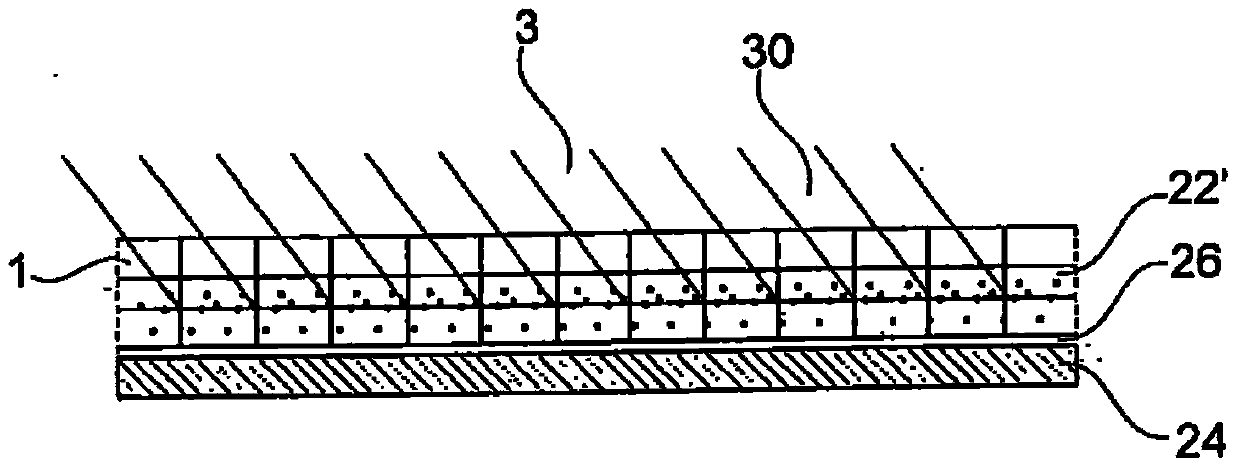

[0054] figure 1 Schematic diagram showing a cross-section through a textile covering (1) onto which a three-layer membrane (2) made of several membrane layers (22, 24, 26) is laid . Facing said fabric covering (1) and laying on said fabric covering first surface (11), the force-transmitting conveyor belt on the later outer surface is a first layer (22) of a first thermoplastic material , this first layer is formed after fixation of the multilayer film (2) with the figure 2 The first coating of the impregnated area is also shown in detail in . Said second layer (24) is a thermoplastic top layer which is also closed after fixing of said multilayer film and said layer (26) is an intermediate layer, here a copolyamide for said layer (22) An interposer is attached which allows peeling of the opposing layer (24).

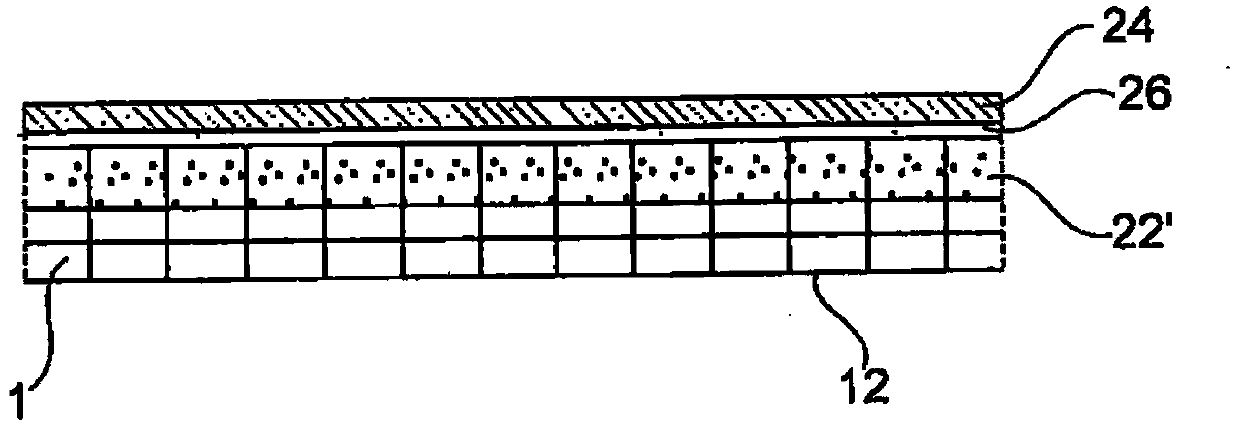

[0055] figure 2 shown in figure 1 The examples shown in , after applying heat and if necessary pressure to the surface of the multilayer film. The first layer (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com