High-strength honeycomb type low-temperature SCR denitration catalyst and preparation method thereof

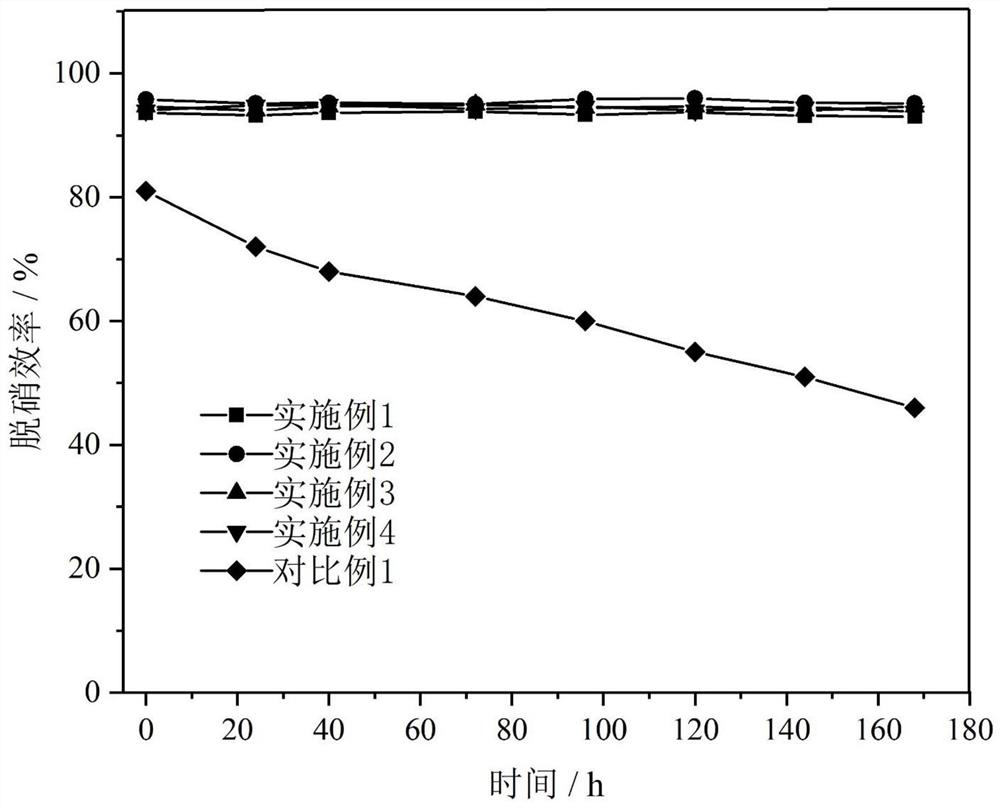

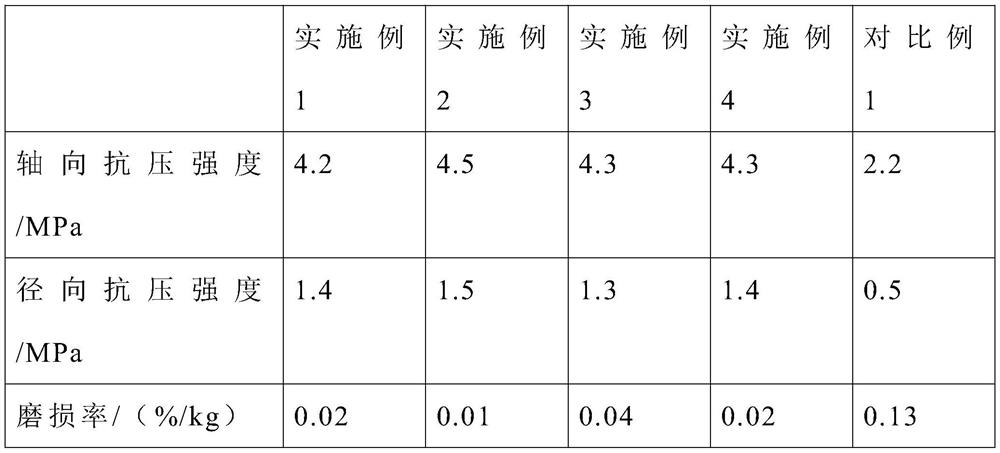

A denitrification catalyst and honeycomb technology, which is applied in the field of high-strength honeycomb low-temperature SCR denitrification catalyst and its preparation, can solve the problems of poor low-temperature activity and prone to sulfur poisoning mechanical properties, and achieve improved low-temperature activity, significant catalytic decomposition, The effect of enhancing the wear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of preparation method of high-strength honeycomb low-temperature SCR denitration catalyst comprises the following steps:

[0029] (1) Dry-mix 545g of titanium dioxide, 300g of alumina and 23g of glass fiber filaments (50mm in length, 2μm in diameter) in a powerful mixer, and evenly disperse the glass fiber filaments into the powder for 1h of mixing time;

[0030] (2) 38.6g ammonium metavanadate is dissolved in 80ml water, 146.9g ammonium heptamolybdate is dissolved in 340ml water, 10.3g antimony acetate is dissolved in 40ml water, and above-mentioned solution is joined in the mixed material of step (1), Then stir evenly, stirring time 2h;

[0031] (3) Add 25g pseudo-boehmite, 10g kaolin, 12g carboxymethyl cellulose, 2g polyacrylamide, 3g polyethylene oxide and 8ml glycerol successively in the mixed material of step (2), the mixing temperature is 60°C, Mixing time 1h;

[0032] (4) 20ml of 1mol / L nitric acid solution is added to the mixed material i...

Embodiment 2

[0037] Embodiment 2: a kind of preparation method of high-strength honeycomb low-temperature SCR denitration catalyst, comprises the following steps:

[0038] (1) Dry-mix 470g of titanium dioxide, 360g of alumina and 20g of glass fiber filaments (60mm in length, 3μm in diameter) in a powerful mixer, and evenly disperse the glass fiber filaments into the powder for 1h of mixing time;

[0039] (2) 64g ammonium metavanadate is dissolved in 100ml water, 122.5g ammonium heptamolybdate is dissolved in 250ml water, 41g antimony acetate is dissolved in 110ml water, and above-mentioned solution is added in the mixed material of step (1), then stir Evenly, stirring time 3h;

[0040] (3) Add 22g pseudo-boehmite, 8g kaolin, 10g carboxymethyl cellulose, 3g polyacrylamide, 2g polyethylene oxide and 10ml glycerol successively in the mixed material of step (2), the mixing temperature is 70°C, Mixing time 2h;

[0041](4) The nitric acid solution of 15ml 2mol / L is added to the mixed material ...

Embodiment 3

[0046] Embodiment 3: a kind of preparation method of high-strength honeycomb low-temperature SCR denitration catalyst comprises the following steps:

[0047] (1) Dry-mix 540g of titanium dioxide, 300g of alumina and 18g of glass fiber filaments (55mm in length, 2μm in diameter) in a powerful mixer, and evenly disperse the glass fiber filaments into the powder for 1h of mixing time;

[0048] (2) 51.4g ammonium metavanadate is dissolved in 120ml water, 98g ammonium heptamolybdate is dissolved in 190ml water, 82g antimony acetate is dissolved in 160ml water, and above-mentioned solution is added in the mixed material of step (1), then stir Evenly, stirring time 3h;

[0049] (3) Add 23g pseudo-boehmite, 9g kaolin, 9g carboxymethyl cellulose, 2g polyacrylamide, 4g polyethylene oxide and 15ml glycerol successively in the mixed material of step (2), mixing temperature 65 ℃, Mixing time 2h;

[0050] (4) The nitric acid solution of 12ml 3mol / L is added to the mixed material in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com