Honeycomb type arsenic poisoning-resistant SCR denitration catalyst and preparation method thereof

A denitration catalyst, arsenic poisoning technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as poor mechanical properties, prone to alkali metal poisoning, etc., to improve adhesion , The effect of improving catalyst strength and enhancing wear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

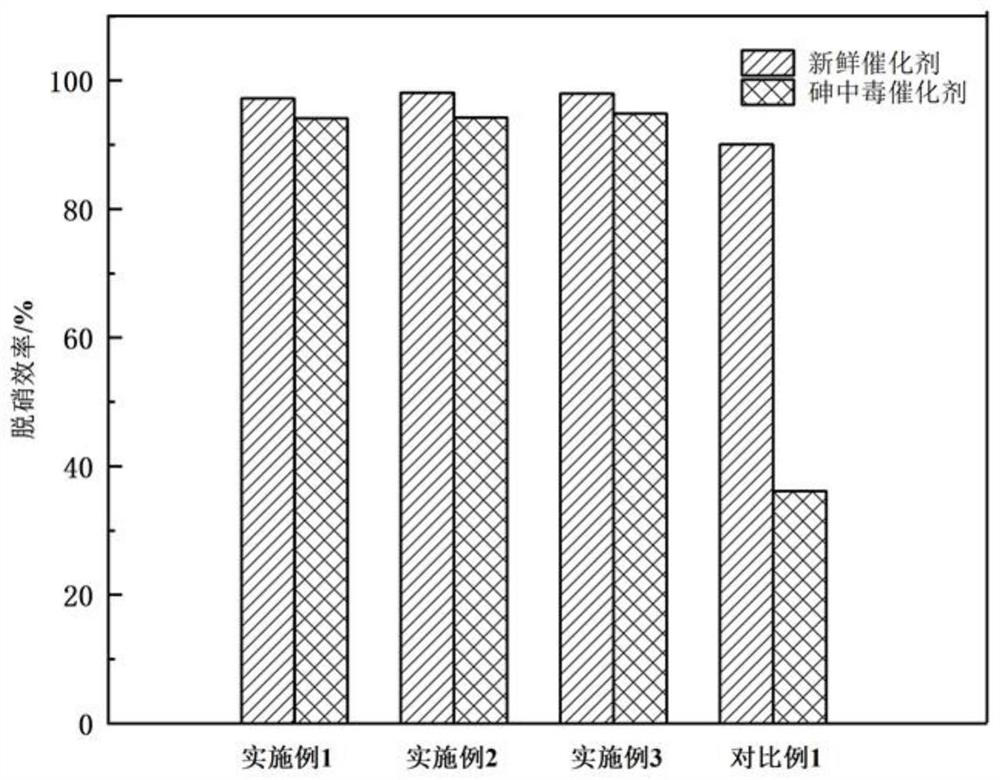

Examples

Embodiment 1

[0029] Embodiment 1: A preparation method of a cellular anti-arsenic poisoning SCR denitrification catalyst, comprising the following steps:

[0030] (1) Dry mix 700g of titanium dioxide, 50g of silicon micropowder, 100g of fumed silica and 20g of glass fiber filaments (60mm in length, 2μm in diameter) in a powerful mixer, and evenly disperse the glass fiber filaments into the powder, Mixing time 1h;

[0031] (2) 38.6g ammonium metavanadate is dissolved in 90ml water, 122.5g ammonium heptamolybdate is dissolved in 240ml water, 52.8g praseodymium nitrate is dissolved in 130ml water, and above-mentioned solution is joined in the mixed material of step (1), Then stir evenly, stirring time 2h;

[0032] (3) Add 18g pseudo-boehmite, 12g bentonite, 10g hydroxyethyl cellulose, 2g polyacrylamide, 3g polyethylene oxide and 6g squash powder successively in the mixed material of step (2), mixing temperature 60 ℃, mixing time 1h;

[0033] (4) 20ml of 1mol / L nitric acid solution is added...

Embodiment 2

[0038] Embodiment 2: A preparation method of a cellular anti-arsenic poisoning SCR denitrification catalyst, comprising the following steps:

[0039] (1) Dry mix 600g of titanium dioxide, 70g of silica powder, 130g of fumed silica and 25g of glass fiber filaments (70mm in length, 3μm in diameter) in a powerful mixer, and evenly disperse the glass fiber filaments into the powder, Mixing time 1h;

[0040] (2) 64.3g ammonium metavanadate is dissolved in 115ml water, 147.1g ammonium heptamolybdate is dissolved in 220ml water, 79.2g praseodymium nitrate is dissolved in 135ml water, and above-mentioned solution is joined in the mixed material of step (1), Then stir evenly, stirring time 3h;

[0041] (3) Add 16g pseudo-boehmite, 15g bentonite, 9g hydroxyethyl cellulose, 3g polyacrylamide, 3.5g polyethylene oxide and 8g squash powder successively in the mixed material of step (2), mixing temperature 55°C, mixing time 2h;

[0042] (4) Add the nitric acid solution of 10ml 2mol / L to t...

Embodiment 3

[0047] Embodiment 3: A preparation method of a cellular anti-arsenic poisoning SCR denitrification catalyst, comprising the following steps:

[0048] (1) Dry-mix 640g of titanium dioxide, 60g of silica powder, 120g of fumed silica and 18g of glass fiber filaments (length 65mm, diameter 2.5μm) in a strong mixer, and evenly disperse the glass fiber filaments into the powder , mixing time 2h;

[0049] (2) 51.4g ammonium metavanadate is dissolved in 130ml water, 122.5g ammonium heptamolybdate is dissolved in 350ml water, 105.5g praseodymium nitrate is dissolved in 240ml water, and above-mentioned solution is added in the mixed material of step 1.1, then stir Evenly, stirring time 2h;

[0050] (3) Add 20g pseudo-boehmite, 12g bentonite, 6g hydroxyethyl cellulose, 2g polyacrylamide, 2g polyethylene oxide and 12g squash powder successively in the mixed material of step (2), mixing temperature 50 ℃, mixing time 1.5h;

[0051] (4) Add the nitric acid solution of 10ml 3mol / L to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com