Thin woven fabric

A thin fabric and fabric technology, which is applied in the field of fabrics for inner bags and inner bag fabrics, can solve the problems of low tear strength and wear strength, and achieve the effect of soft down-proof and excellent wear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

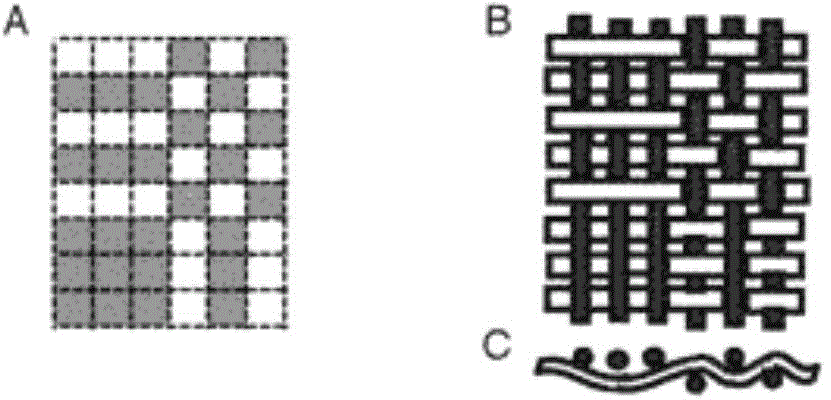

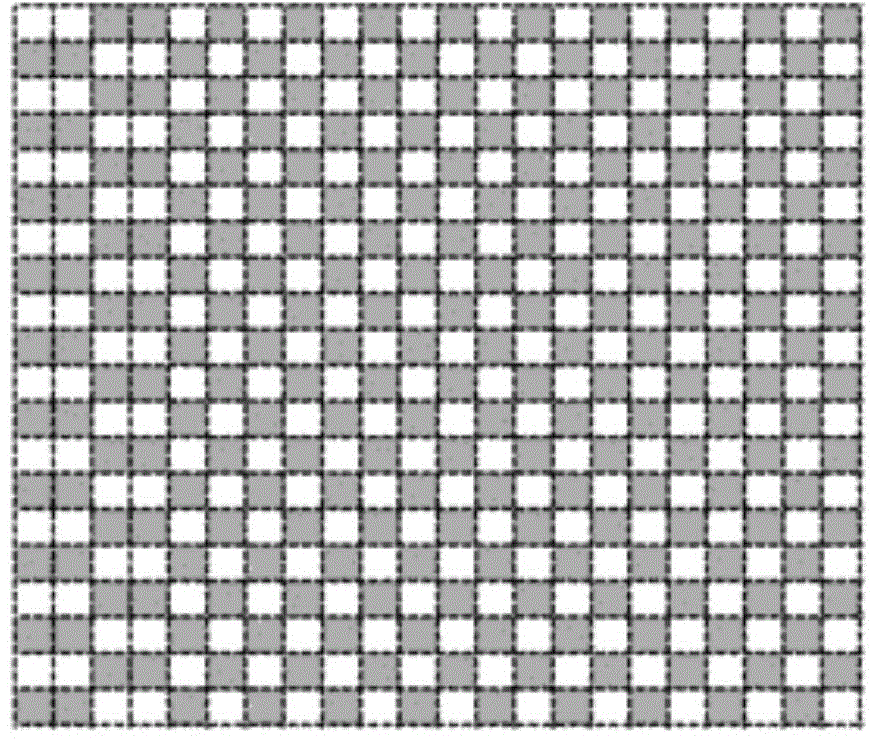

[0075] Water jet loom is used for weaving, warp and weft are polyester filaments with intrinsic viscosity [η] of 0.85 and 11 decitex 10 filaments, weaving figure 1 lattice weave fabric. The obtained fabric is scoured and pre-shaped according to the usual method, dyed with a liquid flow dyeing machine, dried, and then processed by the DIP-NIP method. Nikka Chemical Co., Ltd.’s Nikka Silicone DM- After drying the emulsion of 100E 1% and 0.5% of anionic surfactant at 140°C, it was subjected to hot calendering at 160°C. The amount of silicone resin attached was 0.8 wt%.

[0076] The characteristic of the fabric obtained is as shown in table 1, and the weight per unit area of fabric is 32g / m 2 , the number of intersections of warp and weft is 60025 / inch 2 , the proportion of non-constrained points was 29.2%, and the tear strength was 10.5N in the longitudinal direction and 12N in the transverse direction.

[0077] The texture of the gray fabric is very good, and when this fab...

Embodiment 2

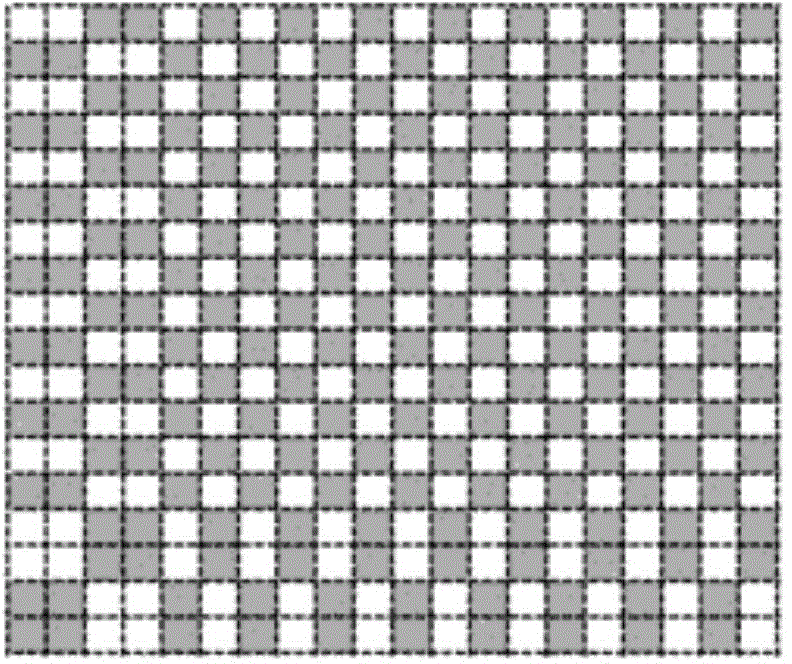

[0079] Warp and weft use polyester filaments with a W-shaped cross-section whose intrinsic viscosity [η] is 0.87 and 17 decitex 18 filaments have a profile degree of 3.2, according to figure 2 Weaving and processing were carried out in the same manner as in Example 1 except that the weave was woven.

[0080] The characteristic of the obtained fabric is as shown in table 1, and the weight per unit area of fabric is 31g / m 2 , the number of intersections of warp and weft is 44000 / inch 2 , the proportion of non-constrained points was 4.5%, and the tear strength was 9.1N in the longitudinal direction and 8.2N in the transverse direction.

[0081] The texture of the gray fabric is very good, and when the fabric is used in a down jacket, it is light, soft, and strong enough.

Embodiment 3

[0083] The warp uses polyester filaments with a W-shaped cross-section whose intrinsic viscosity [η] is 0.87 and 24 decitex 18 filaments with a degree of irregularity of 3.2, and image 3 Weaving and processing were carried out in the same manner as in Example 1 except that the weave was woven.

[0084] The properties of the resulting fabric are shown in Table 1, and the weight per unit area of the fabric is 37g / m 2 , the number of intersections of warp and weft is 30960 / inch 2 , the proportion of non-constrained points was 10.6%, and the tear strength was 10.1N in length and 11N in width. When the fabric is used in down jackets, it is light, soft and strong enough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com