Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as chlorine corrosion and environmental protection problems that cannot be excluded, and achieve a simple and easy preparation method, good adhesion performance, and improved Effect of Aromatic Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of phosphoraluminum glue with Al / P=0.45:1:

[0042] 1200 grams of aluminum hydroxide (containing Al 2 o 3 65%) with 6500 grams of deionized water to disperse and beat, then raise the temperature to 100±5°C, stir and slowly add 3918.5 grams of concentrated phosphoric acid, and keep reacting at 100±5°C for 1 hour until it becomes a transparent colloid. After analysis, the phosphoraluminum glue contains 7.6% Al 2 o 3 , containing 23.5% by weight of P 2 o 5 , Al / P=0.45.

Embodiment 2

[0044] Preparation of phosphoraluminum glue with Al / P=0.75:1:

[0045] 1200 grams of pseudoboehmite (containing Al 2 o 3 65%) with 4200 grams of deionized water to disperse and beat, then raise the temperature to 100±5°C, slowly add 2351 grams of concentrated phosphoric acid with stirring, and keep reacting at 100±5°C for 2 hours until it becomes a transparent colloid. After analysis, the phosphoraluminum glue contains 11.4% by weight Al 2 o 3 , containing 21.2 wt% P 2 o 5 , Al / P=0.75.

Embodiment 3

[0047] 1500 grams (dry basis) of rare earth-containing ultra-temperature Y molecular sieve and 400 grams (dry basis) of ZSM-5 molecular sieve and 4000 grams of water were beaten evenly to make molecular sieve slurry for later use.

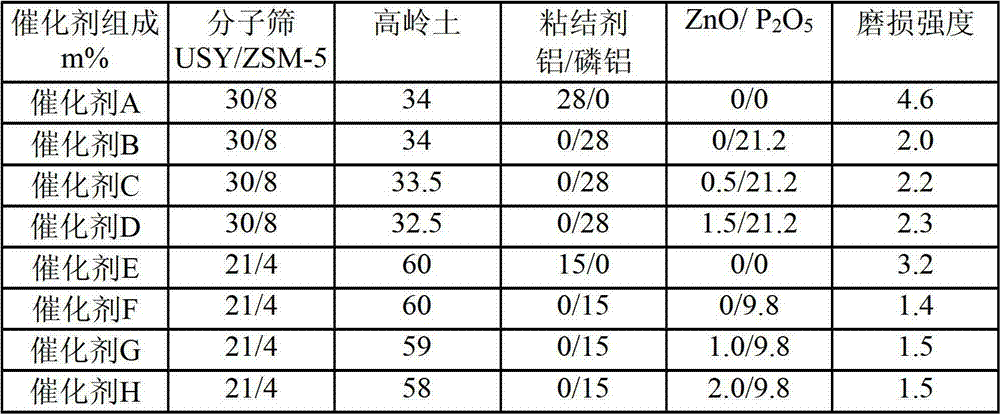

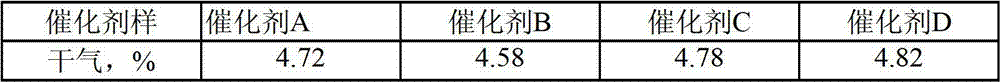

[0048] Beat 1,700 grams of kaolin and 4,000 grams of water evenly, add 1,400 grams (in Al 2 o 3 Calculated) aluminum sol, beating evenly, then adding the prepared molecular sieve slurry, spray drying after homogenization, and roasting at 650°C for 3 hours to obtain catalyst A. Its composition and wear strength are shown in Table 1, and the evaluation results of heavy oil micro-reflection are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com