Adhesive tape, in particular wrapping tape

A technology of adhesive tape and wrapping tape, applied in the direction of adhesive, film/sheet adhesive, textile, etc., can solve problems such as no solution for this, and achieve high wear strength, high cutting strength and impact the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

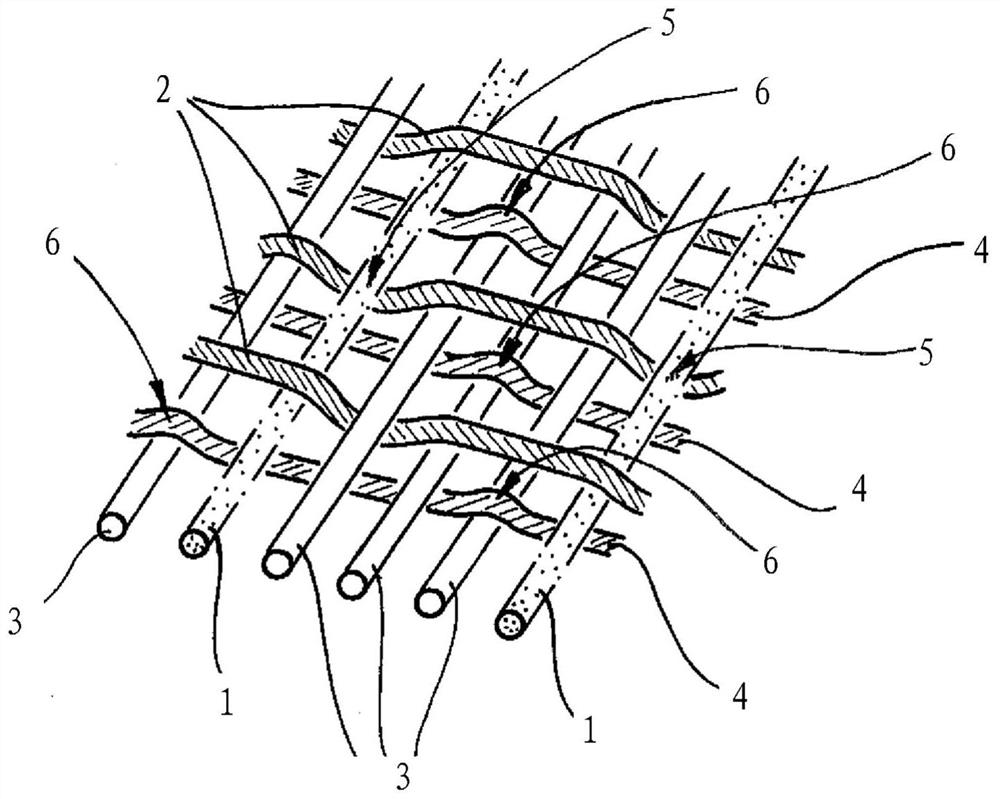

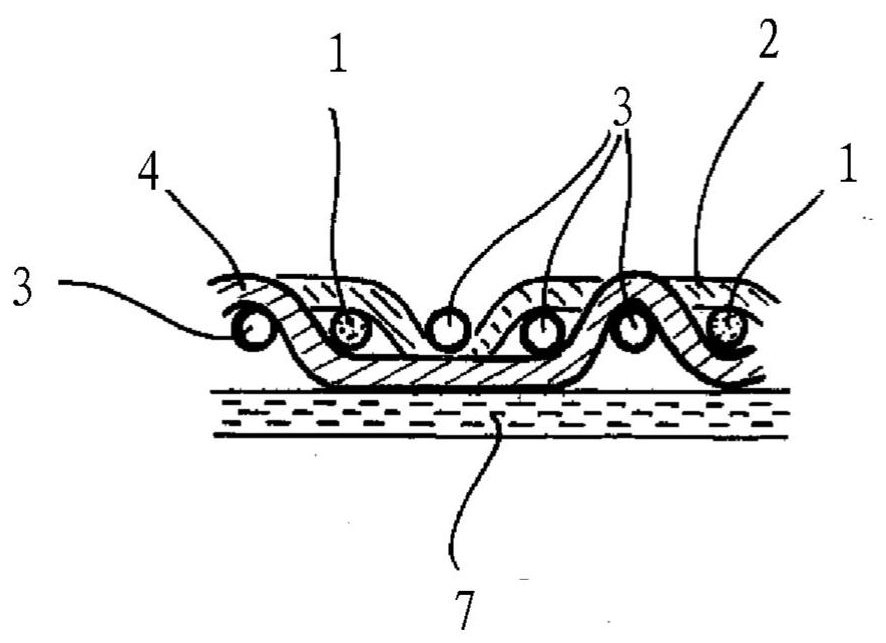

[0026] The figure shows an adhesive tape consisting of a carrier 1 , 3 , 2 , 4 in the form of a single-woven, wear-resistant textile. The textile supports 1 , 3 , 2 , 4 are provided with an adhesive coating 7 . The adhesive coating 7 is generally located on the inside of the textile carrier 1 , 3 , 2 , 4 , to be precise in the state of being wound, for example, on one or more cables.

[0027] The wear-resistant textile carrier 1 , 3 , 2 , 4 is designed overall as a single fabric. In fact, the single fabric is provided with wear-resistant warp threads 1 , 3 in three layers. Warp yarns 1, 3 are not connected to each other. In fact, according to figure 1 It can be seen that firstly warp threads 1 are provided, which define the outer layer. Furthermore, a plurality of warp threads 3 are provided, which form the inner layer of the single fabric or woven fabric carrier 1 , 3 , 2 , 4 .

[0028] The warp threads 1 , 3 are coupled by means of the weft threads 2 , 4 to form a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com