Solid silicon aluminum phosphorus molecular sieve forming method and device

A silicon-alumino-phosphorus molecular sieve and silicon-alumino-phosphorus technology, which is applied in molecular sieve catalysts, molecular sieves and alkali-exchanged phosphates, molecular sieve-specific silico-aluminophosphates, etc. , Improve the wear strength and avoid the effect of hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

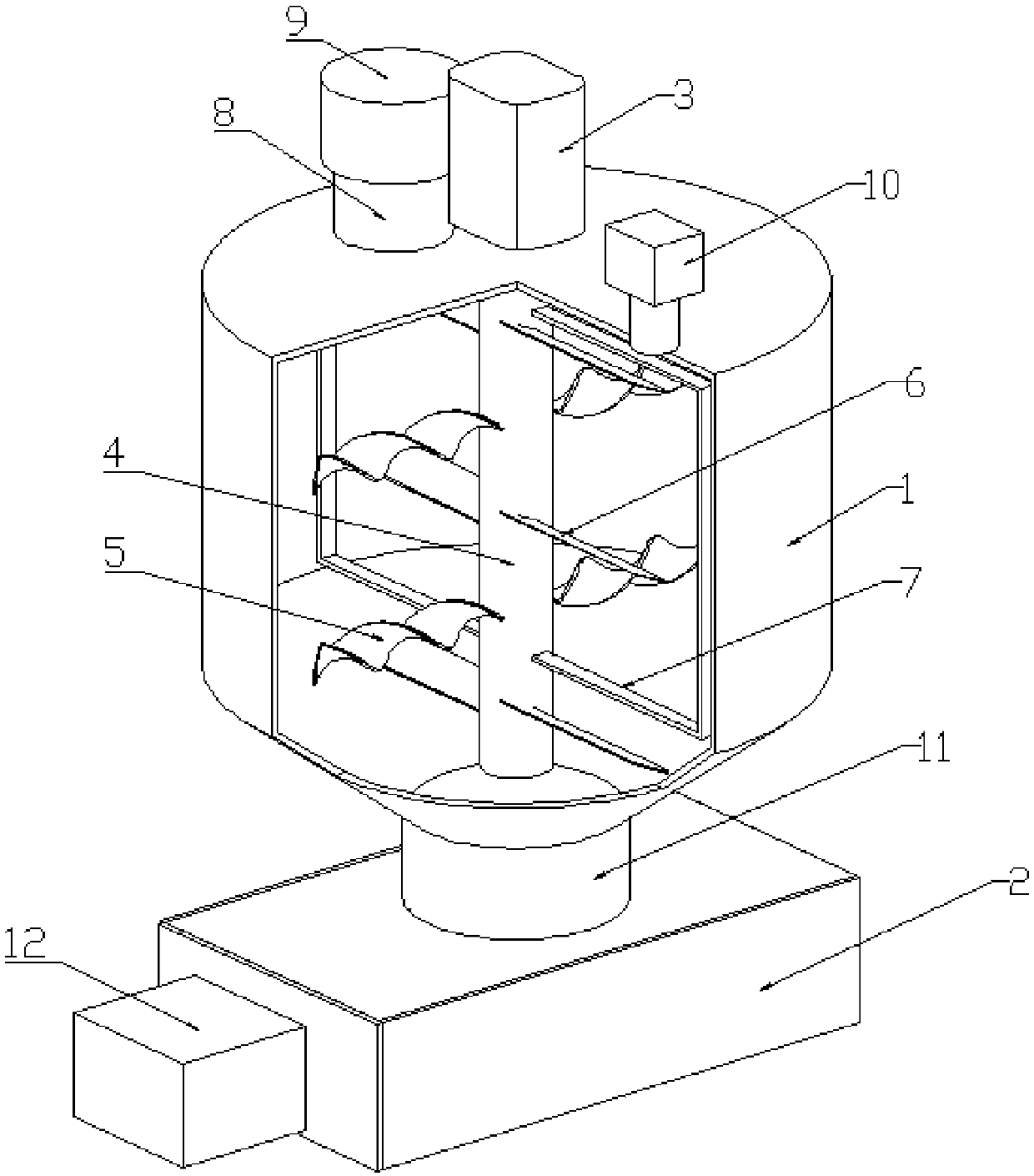

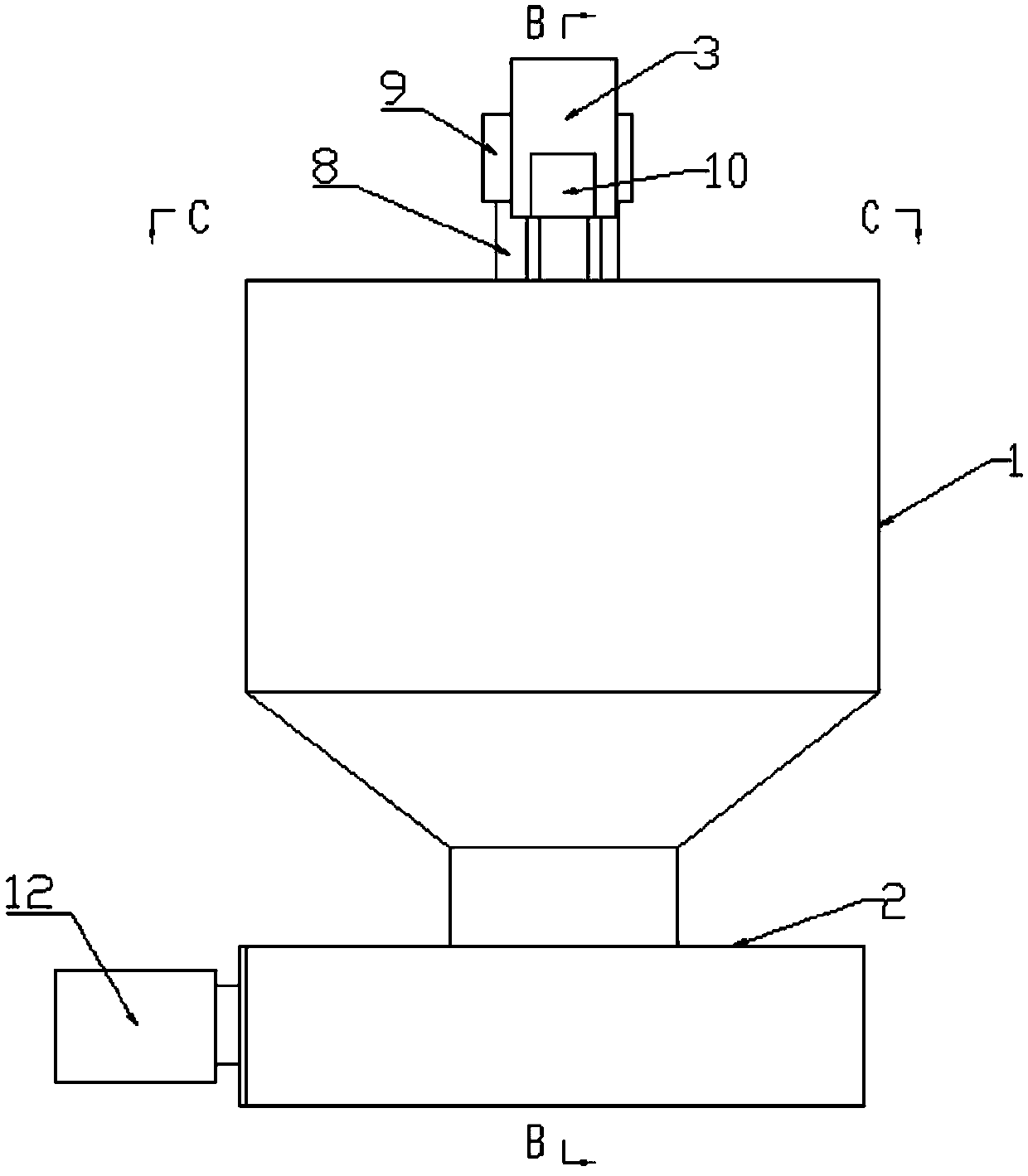

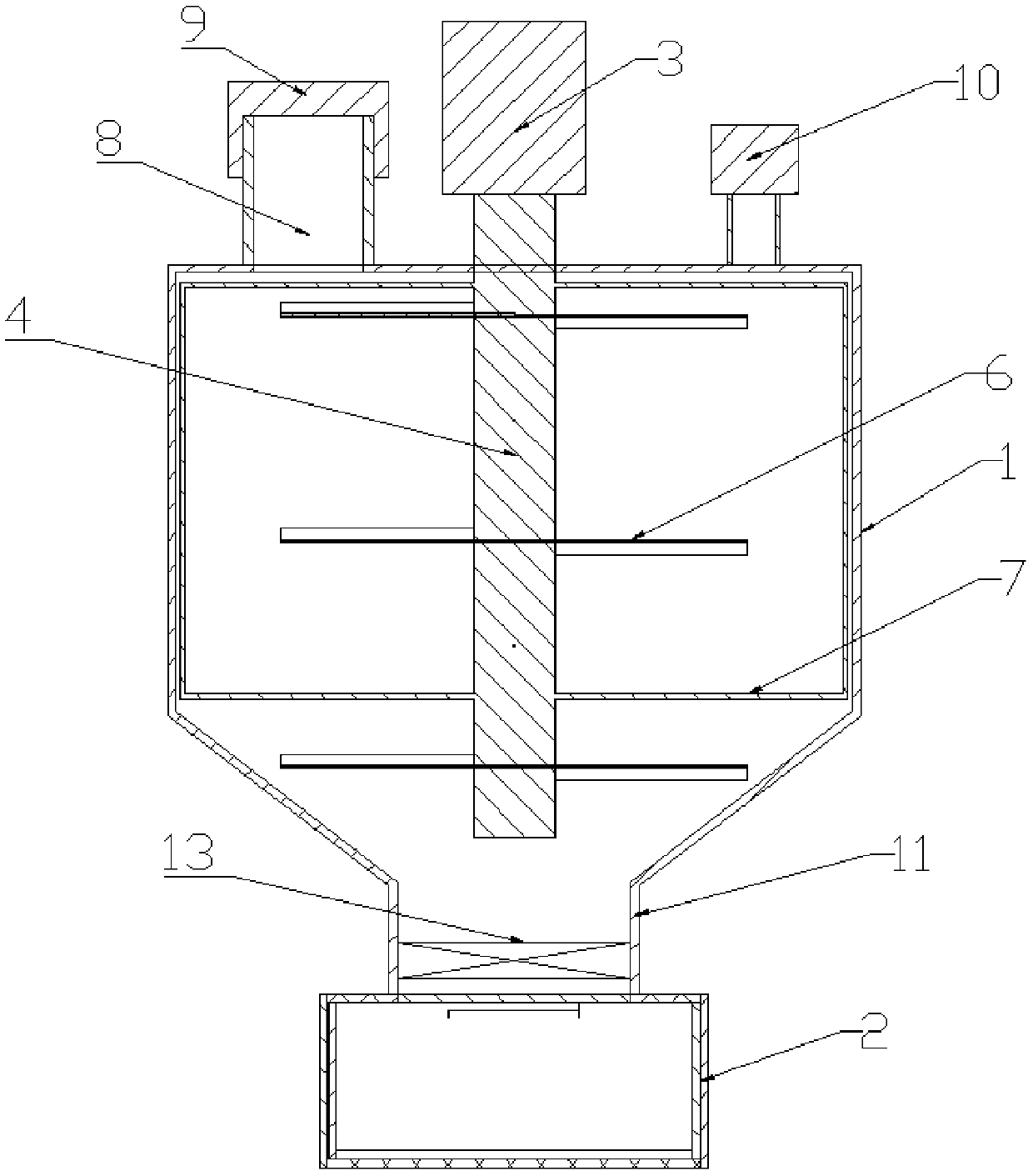

[0060] A solid silicon aluminum phosphorus molecular sieve forming device, comprising a batching kettle 1 and a pusher 2;

[0061] The top of the batching kettle 1 is provided with a feed inlet 8, and the bottom is provided with a discharge outlet, and the feed inlet 8 is provided with a sealing cover 9, and the sealing cover 9 can be threadedly connected with the feeding inlet 8; the batching kettle 1 is also connected with Vacuum pump 10, the batching kettle 1 is also provided with a pressure gauge for detecting the pressure; the inside of the batching kettle 1 is provided with an agitator, and the agitator includes a rotating shaft 4 that is vertically arranged on the inside of the batching kettle 1 and is arranged on the rotating shaft 4 The stirring blade and the scraping frame 7 on the top, the scraping frame 7 is in the shape of a mouth, and the side of the scraping frame 7 is attached to the inner wall of the batching kettle 1, and the scraping frame 7 is made of 304 st...

Embodiment 2

[0071] On the basis of the above embodiments, for example, the stirring blades include first stirring blades 5 and second stirring blades 6 arranged alternately from top to bottom; the first stirring blades 5 are in a spiral structure; the second stirring blades The two stirring blades 6 are sheet-like structures and are arranged obliquely relative to the horizontal plane.

[0072] Specifically, the first stirring blades 5 are in 2 groups, each group has 2 and are arranged symmetrically, the second stirring blades 6 are in 3 groups, each group has 2 and are symmetrically arranged, and the first stirring blades 5 and the second stirring blades 6 intervals are set; the distance between the stirring blade at the bottom of the rotating shaft 4 and the bottom of the batching kettle 1 is 0.2-0.5m, and the stirring blade is made of 304 stainless steel or above.

[0073] Wherein, the second stirring blade 6 of sheet-like structure provides conventional stirring mode, and the first sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com