Device for monitoring stress states of leather shoes during pressing

A technology of stress state and leather shoes, which is applied to the measurement device of feet or shoe lasts, shoemaking machinery, footwear, etc., which can solve the problems affecting the yield of leather shoes and the inability to monitor and display leather shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

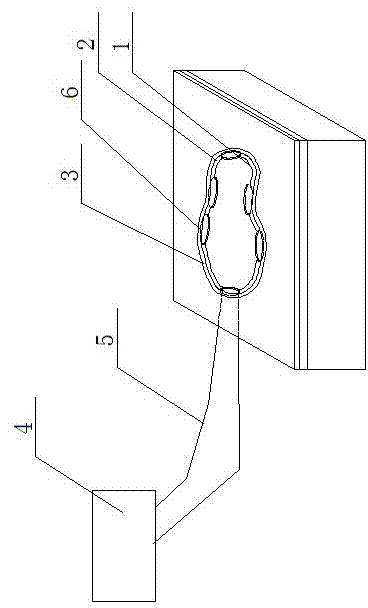

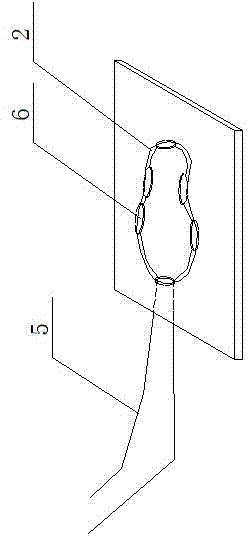

[0010] Such as figure 1 and figure 2 A device for monitoring the force state of leather shoes when they are pressed together includes a bottom mold 1, a pressure-resistant layer 2 is arranged on the bottom mold 1, a wear-resistant layer 3 is arranged on the pressure-resistant layer 2, the wear-resistant layer 3 and the wear-resistant layer The pressure layer 2 is provided with a mold cavity consistent with the shoe shape on the bottom mold, and a pressure sensor 6 is embedded in the pressure-resistant layer near the mold cavity, and the pressure sensor is connected to the pressure display 4 through a wire. In the present invention, pressure sensors 6 are embedded in the front toe part of the pressure-resistant layer close to the mold cavity, the plantar part corresponding to the inner and outer ankles, the heel opening corresponding to the inner and outer ankles, and the end point of the heel. 5. Add pressure sensors to the pressure-resistant layer corresponding to the six p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com