A method for the adhesion test and quantitative evaluation of cold patched asphalt

A technology for cold patching asphalt and quantitative evaluation, which is applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of high subjectivity in judgment, difficult to accurately calculate the shedding area, and inability to quantitatively evaluate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A cold-patch asphalt adhesion test and quantitative evaluation method, comprising the following steps:

[0029] S1: According to the mix ratio design of the cold patching material, 95.2g of domestic Yitong cold patching asphalt and 1904.8g of limestone aggregate were selected to make the cold patching material, and the cold patching material was divided into two groups of test pieces with a mass of 500g. 1-1 and 1-2, where 1-1 and 1-2 each have two sets of parallel test pieces;

[0030] S2: Specimen 1-1 was preserved at room temperature for 40 hours; Specimen 1-2 was vacuum saturated with water for 15 minutes under the condition of 98.5KPa, and after returning to normal pressure for 15 minutes, Specimen 1-2 was taken out of the water and placed in the in a plastic bag;

[0031] S3: Add 10ml of water to the plastic bag, and put it into a constant temperature refrigerator at -18°C for 16.5 hours;

[0032] S4: Take out the test piece 1-2 in the plastic bag, and immediate...

Embodiment 2

[0050] The difference from Example 1 is:

[0051] S1: Select 95.2g of American QPR cold patch asphalt and 1904.8g of limestone aggregate to make cold patch, divide the cold patch into two groups of test pieces with a mass of 500g, and the test piece numbers are 2-1 and 2-2, respectively. Among them, 2-1 and 2-2 each have two sets of parallel test pieces;

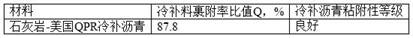

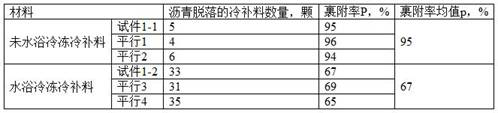

[0052] Table 2-1: Coating rate of US QPR cold-patched asphalt aggregates

[0053]

[0054] Table 2-2: American QPR cold-patch asphalt aggregate coating rate ratio and US QPR cold-patch asphalt adhesion grade

[0055]

[0056] Embodiment two conclusion:

[0057] The adhesion grade of American QPR cold-patch asphalt is good, so the American QPR cold-patch asphalt can be applied to road engineering environments with a lot of rain.

experiment example 1

[0059] Take 500g of the domestic Yitong cold patched asphalt mixture made in Example 1 as the test piece 3-1, and the test piece 3-1 adopts the T0616- 1993 Adhesion test between asphalt and coarse aggregate (boiling method) for adhesion evaluation;

[0060] Get 500g of U.S. QPR cold-patch asphalt mixture made in Example 2 as specimen 4-1, and specimen 4-1 adopts T0616-1993 in "JET-E20-2011 Highway Engineering Asphalt and Asphalt Mixture Test Regulations" Adhesion test (boiling method) between asphalt and coarse aggregate for adhesion evaluation;

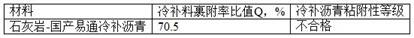

[0061] Table 3: Adhesion grade of cold patch determined by T0616-1993 test method

[0062]

[0063] T0616-1993 test conclusion:

[0064] The adhesion grade of limestone-domestic Yitong cold-patch asphalt mixture is grade 4;

[0065] The adhesion grade of limestone-American QPR cold patch asphalt mixture is 4, and the adhesion performance of the two kinds of asphalt is similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com