Method for modifying surface of high molecular weight polyethylene powder through interfacial polycondensation

A technology of ultra-high molecular weight and polyethylene powder, applied in the field of polymer surface modification, can solve the problem of low physical mixing efficiency, achieve the effect of improving surface hydrophilicity, good treatment effect, and increased bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

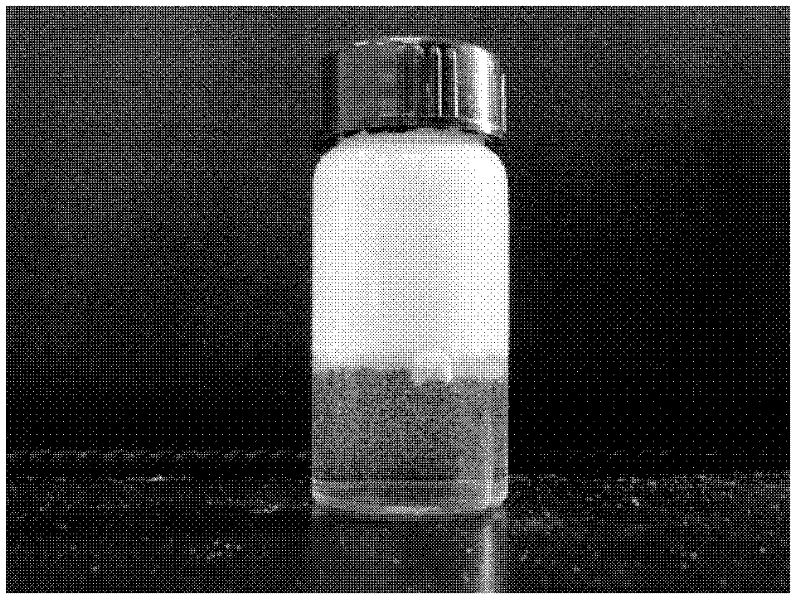

[0045] In this example, the pretreatment process of step 1 is completely consistent with that of the comparative example, the difference is that the UHMWPE powder after pretreatment is subjected to surface modification treatment using the process described in steps 2 to 6, and the specific steps are as follows:

[0046] Step 1: Pre-treatment of UHMWPE powder: Use a 200-mesh sieve to screen out UHMWPE powder with a relatively uniform particle size. The relative molecular weight of the UHMWPE powder is 2 million; then soak the UHMWPE powder in acetone, wash it ultrasonically for 0.5 hours, and remove it by suction filtration Acetone, and then placed in a vacuum oven with a vacuum degree of 0.1Mpa, vacuum-dried at 30°C for 12 hours, and took out the UHMWPE powder for use after drying;

[0047] Step 2: Prepare solution A: Dissolve isophthaloyl dichloride in n-hexane to prepare isophthaloyl dichloride n-hexane solution with a concentration of 0.05g / mL;

[0048] Step 3: Adding to so...

Embodiment 2

[0054] Steps 1 to 4: are identical to steps 1 to 4 in Example 1;

[0055] Step 5: After the UHMWPE powder mixed solution obtained in step 3 is suction-filtered, the solvent is not removed, and the solvent is directly stirred into the melamine aqueous solution prepared in step 4 at one time, and stirred and reacted at a speed of 2600 rpm for 40 minutes;

[0056] Step 6: Filter the mixed solution obtained in Step 5 to remove the solvent, wash with deionized water and acetone three times respectively, and then place it in a vacuum oven with a vacuum degree of 0.1Mpa at 50°C for 4 hours to obtain UHMWPE powder Take it out and set aside.

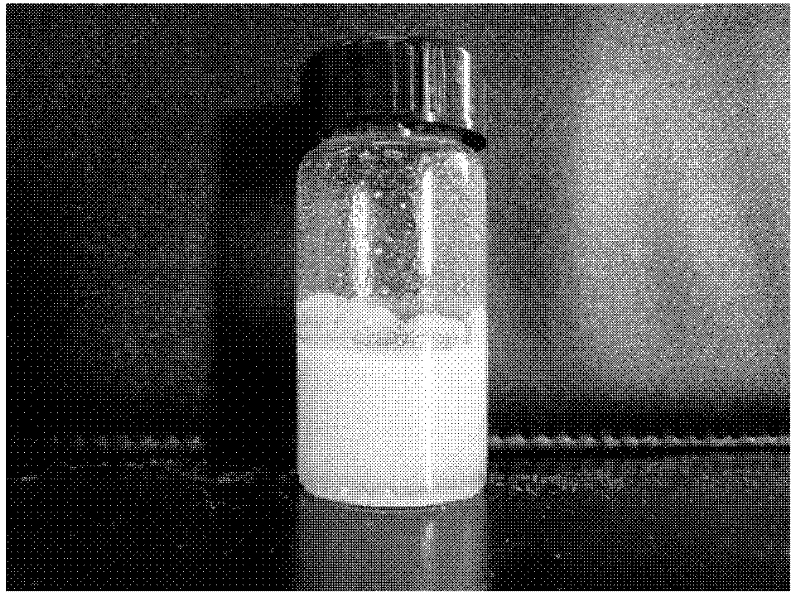

[0057] The dispersion situation of the UHMWPE powder that above-mentioned method obtains in water is as follows image 3 As shown, it can be seen that the dispersibility of UHMWPE powder in water is enhanced, and it can be uniformly dispersed in water instead of floating on the water surface.

Embodiment 3

[0059] Steps 1 to 4: are identical to steps 1 to 4 in Example 1;

[0060] Step 5: After the UHMWPE powder mixed solution obtained in step 3 is suction-filtered, the solvent is not removed, and the solvent is directly stirred into the triethylenediamine aqueous solution prepared in step 4 at one time, and stirred and reacted at a speed of 2600 rpm for 5 minutes;

[0061] Step 6: Filter the mixed solution obtained in Step 5 to remove the solvent, wash with deionized water and acetone three times respectively, and then place it in a vacuum oven with a vacuum degree of 0.1Mpa at 50°C for 4 hours to obtain UHMWPE powder Take it out and set aside.

[0062] The UHMWPE powder obtained by the above method has enhanced dispersibility in water and can be evenly dispersed in water instead of floating on the water surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com