Fibre-optical prefabricated bar processing apparatus by plasma technology

A technology of optical fiber preform and plasma, which is applied in glass manufacturing equipment, manufacturing tools, optics, etc., can solve problems such as difficult heat dissipation and complex adjustment, and achieve good results and enhanced cooling and shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be explained in detail below in conjunction with specific embodiments.

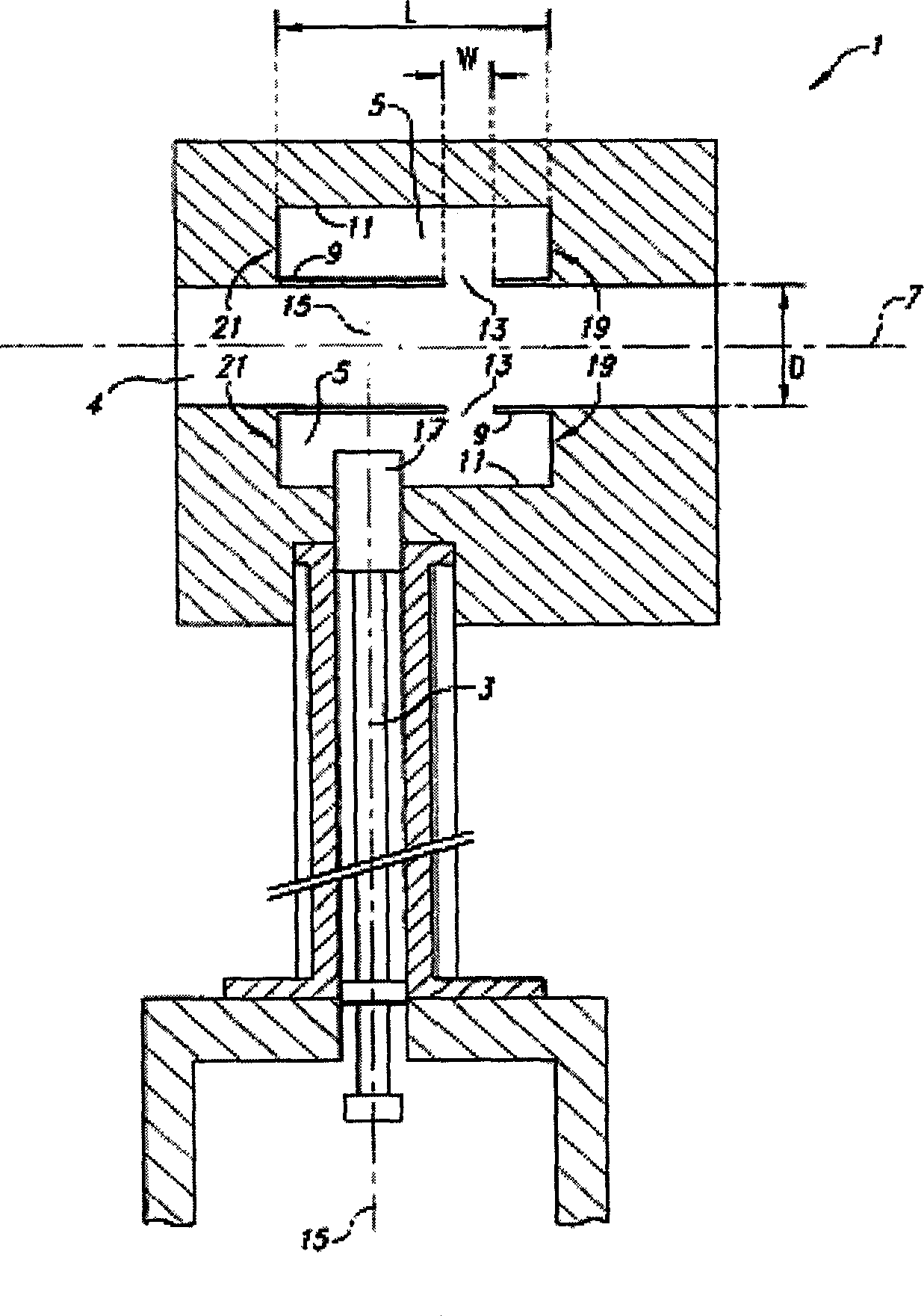

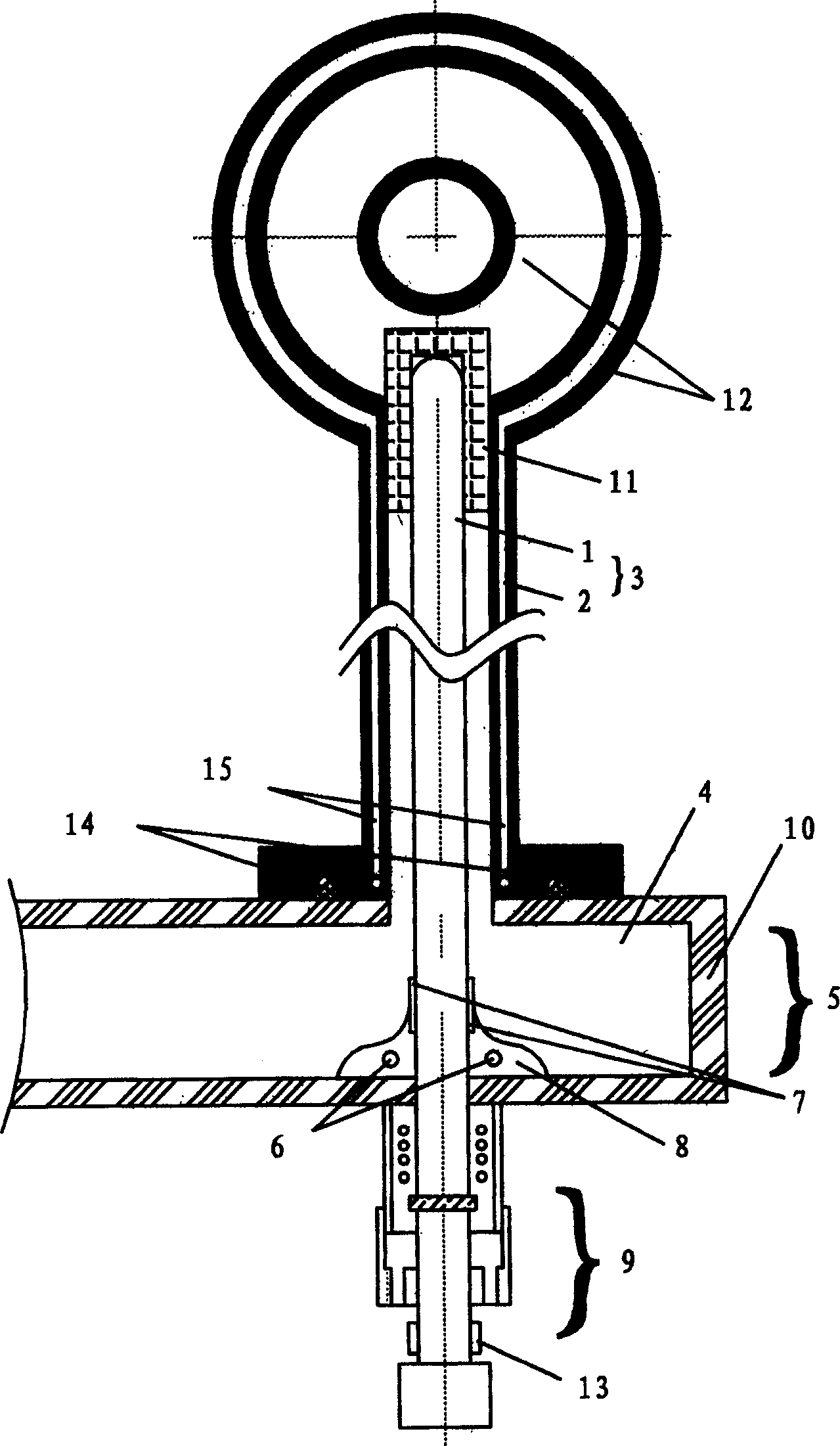

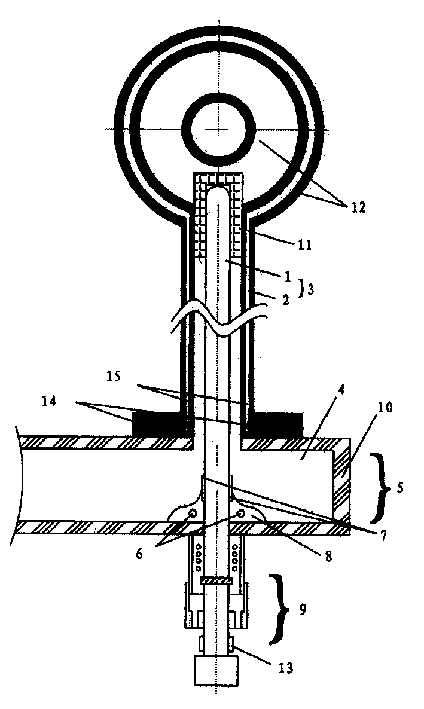

[0015] Such as figure 2 As shown, the embodiment of the optical fiber preform processing equipment of the present invention is composed of several parts: a cylindrical coaxial resonant cavity 12; a waveguide 4 on a short-circuit surface 10; a coaxial line 3 (including an inner conductor 1 and an outer conductor 2); There is a door button type structure 8 of claw-shaped axle sleeve 7; a lifting structure 9 with a lifting counter 13 and additional devices (comprising water cooling pipes 6, 15, anti-leakage device 14 and support member fasteners, etc.).

[0016] The door button structure is welded in the middle of the wide side of the waveguide, and the waveguide model is BJ-22 (size 109.2*54.6mm) or BJ-26 (size 86.4*43.2mm). The position of the short-circuit surface is determined by experiments and welded on the waveguide. Since the inner conductor of the coaxial line is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com