Method for testing effective mixing amount of direct-vat-set high-viscosity asphalt modifier

A technology of asphalt modifier and testing method, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problem of insufficient test indicators of direct-injection asphalt mixture, unknown effective modifier content, and inability to accurately estimate direct-injection asphalt mixture. Issues such as the effective dosage of high-viscosity asphalt mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0039] Such as figure 1 As shown, this embodiment provides a test method for the effective dosage of direct-throwing high-viscosity asphalt modifier, including the following steps:

[0040] The first step is to inspect the basic properties of base asphalt or SBS asphalt, high-viscosity modifier and aggregate.

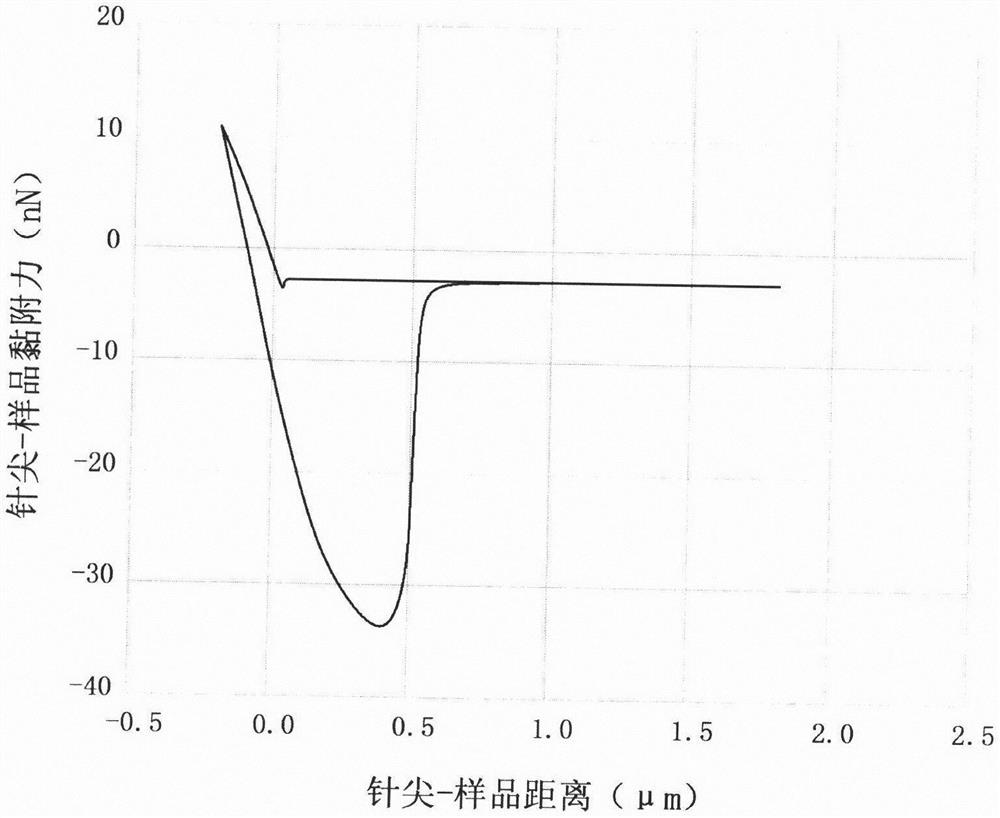

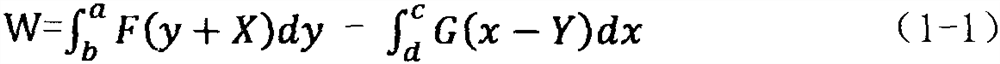

[0041] The second step is to prepare the asphalt mixture by the direct injection method, and then use the asphalt extractor and the rotary evaporator to obtain the direct injection high-viscosity asphalt sample. The specific steps include: using a stirring pot, putting the high-viscosity modifier, stone and mineral powder into the stirring pot, heating and stirring for 1 minute and 30 seconds, then adding base asphalt or SBS pitch and lignocellulose and heating and stirring for 1 minute and 30 seconds, The direct-throwing high-viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com