Paint film scriber

A cross-cutting and paint-film technology, applied in the field of paint-film cross-cutting devices, can solve the problems of lowering the detection accuracy of paint film adhesion, inability to draw grid lines, and inability to accurately draw lines, etc. Positioning, improving the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

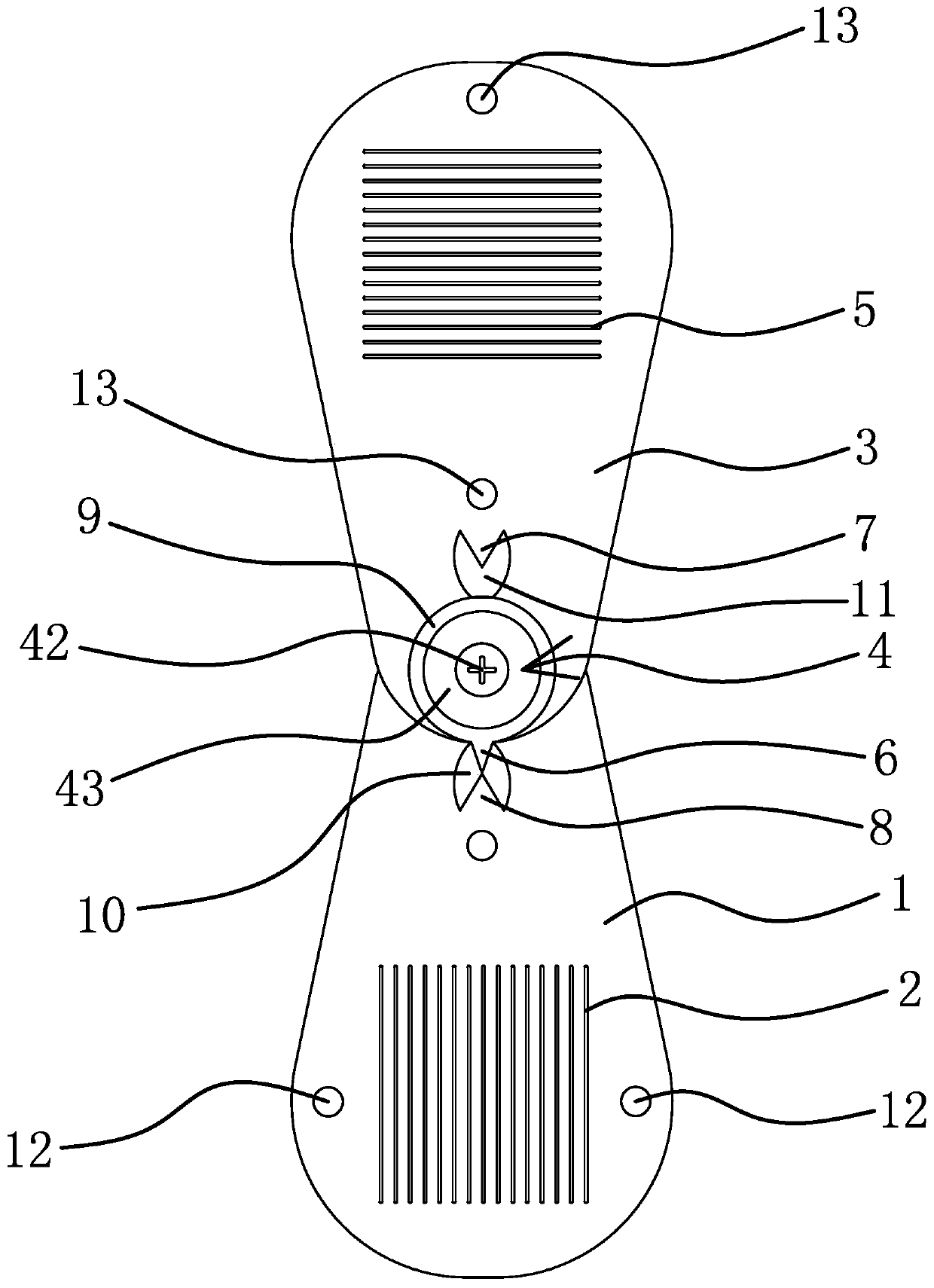

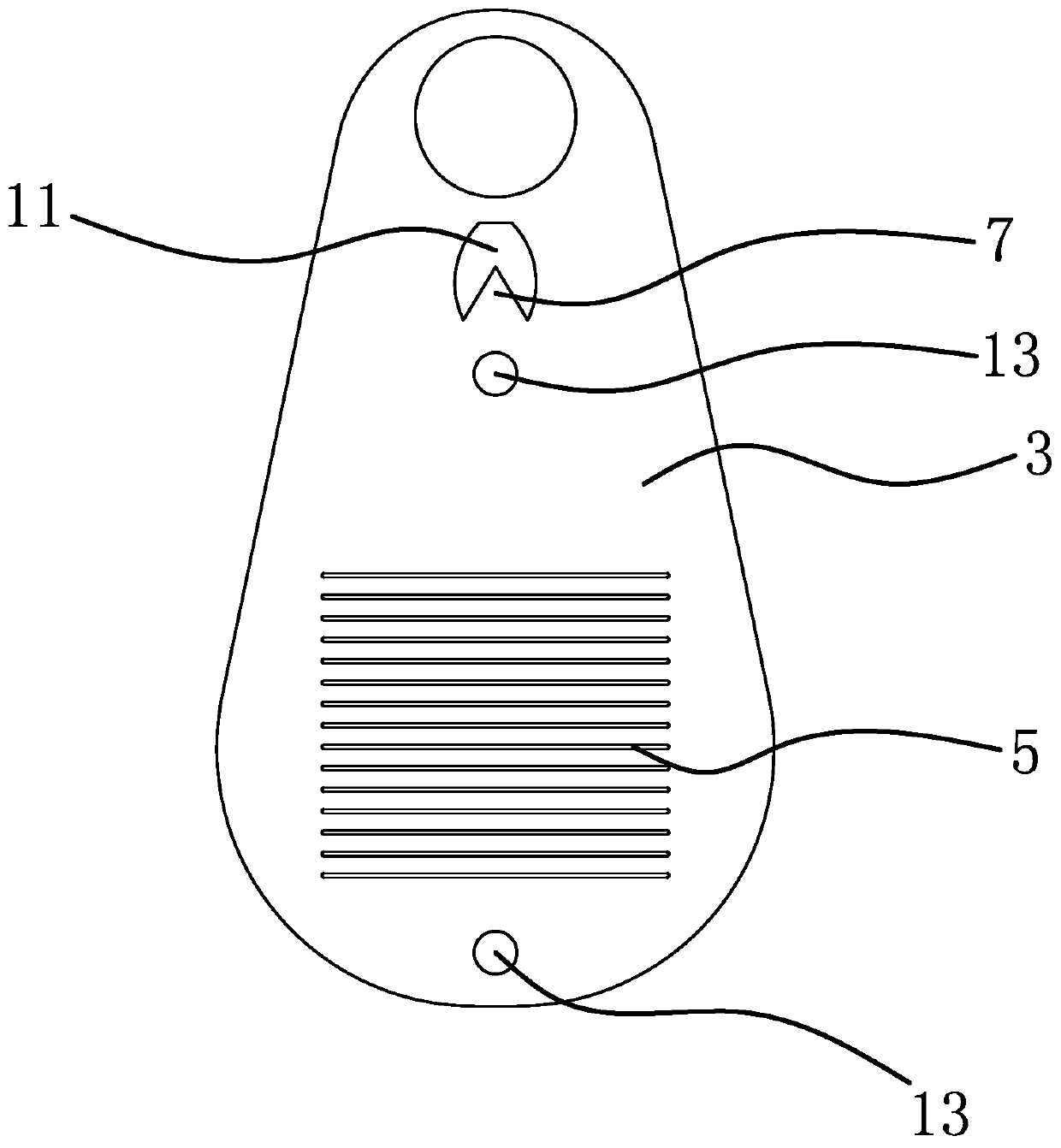

[0033] This paint film scratcher is suitable for detecting metal paint film test boards, and can also detect paint film test boards of wooden materials, such as figure 1 As shown, the paint film scribe includes a first scribe 1 , a second scribe 3 and a positioning member 4 .

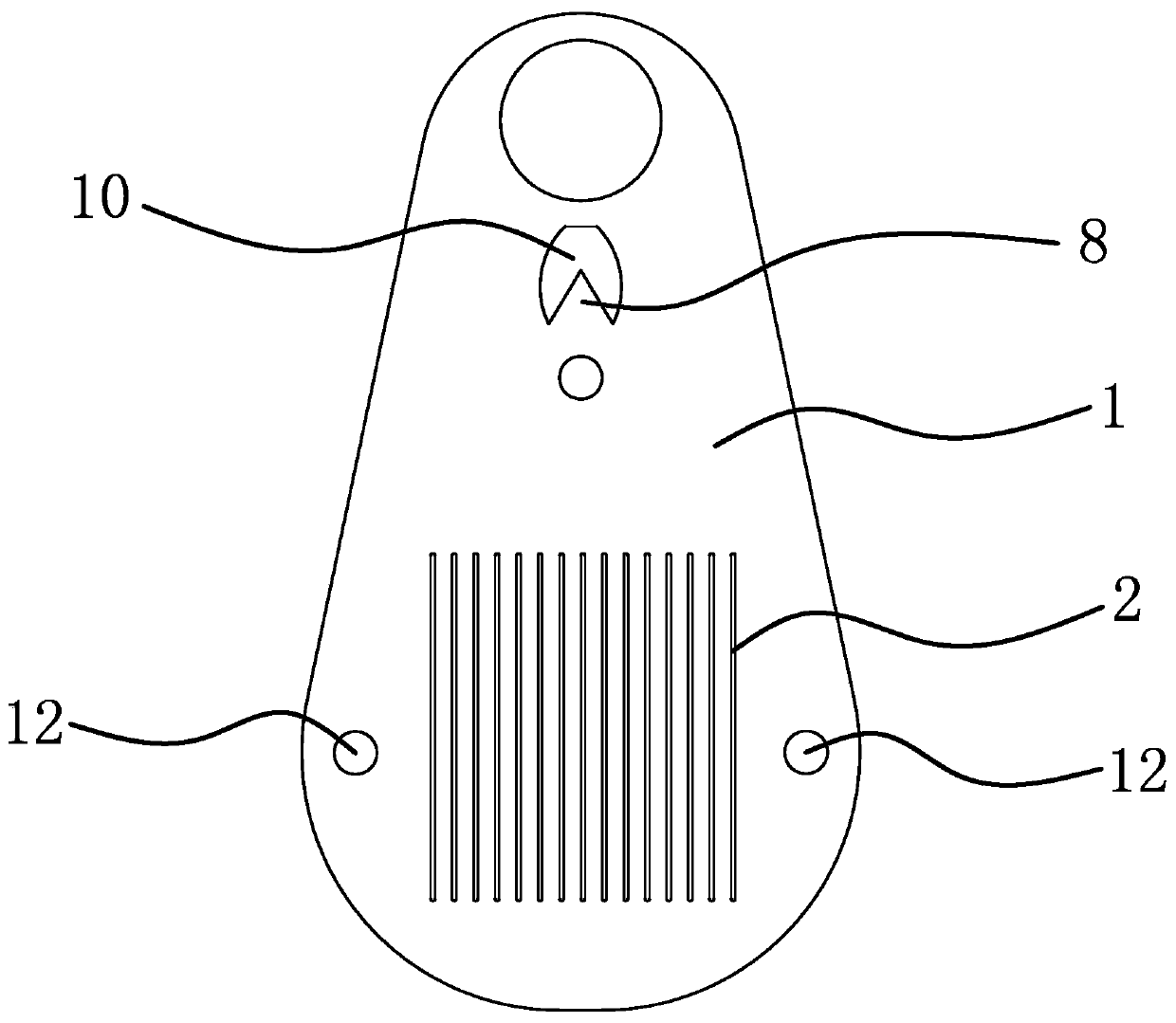

[0034] Such as figure 2 As shown, in the present embodiment, the first cross-cutting plate 1 is provided with fifteen first cross-cut grooves 2 arranged in parallel. In actual production, the number of the first cross-cut grooves 2 can be ten or twenty. . A pair of first anti-skid holes 12 are provided on the first grid plate 1, and a pair of first anti-skid holes 12 are located on both sides of the first grid plate 1, and all the first grid grooves 2 form a first area. The first anti-skid holes 12 are respectively located on both sides of the first area, and the center line of a pair of first anti-skid holes 12 is perpendicular to the first cross-cut groove 2 . One end of the first grid plate 1 has...

Embodiment 2

[0040] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, except that in this embodiment, the plug 44 is made of magnetic material, and the bottom of the plug 44 is not provided with a fixing groove 46 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com