Dust removing device used on filming coating machine base cloth before coating

A technology of dust removal device and film coating machine, which is applied in the direction of surface coating liquid device, coating, mechanical cleaning, etc. It can solve the problems of polluting the base cloth, the base cloth cannot be cleaned thoroughly, and the dust removal cannot be cleaned thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

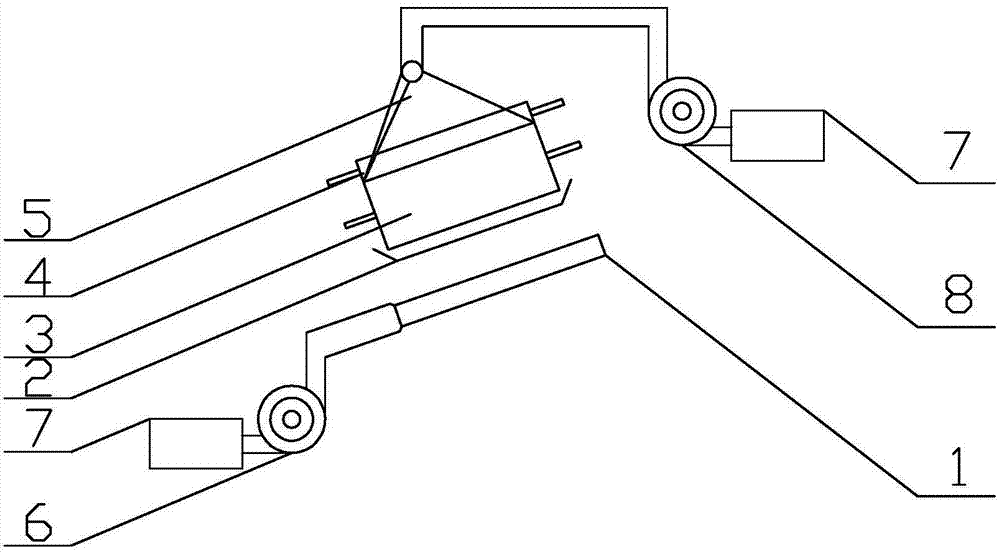

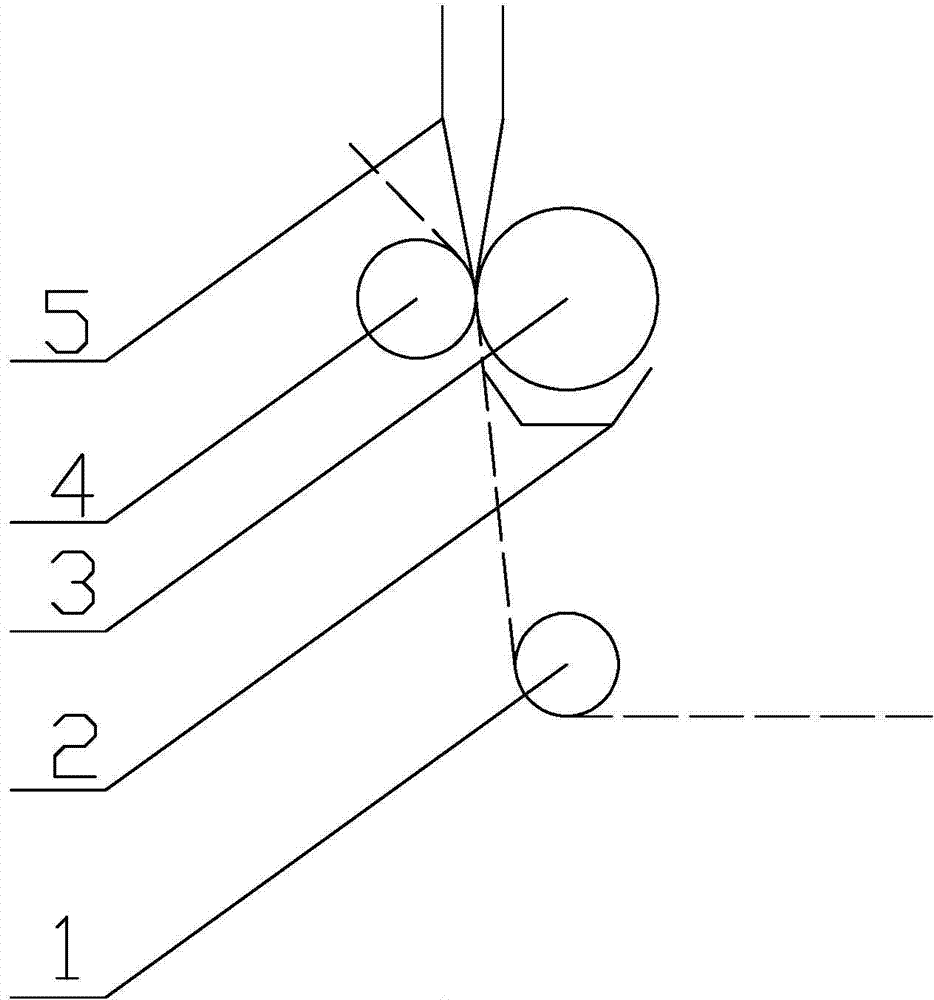

[0020] Embodiment 1: as figure 1 and figure 2 As shown, the dust removal device before coating the base cloth of the film coating machine according to the present invention includes a lower suction pipe 1, a water tank 2, a brush roller 3, a guide roller 4, a suction nozzle 5, a fan and a dust bag 7, and the guide Roller 4 is provided with driving mechanism, guide roller 4 is connected with its driving mechanism, hair brush roller 3 is installed on the same horizontal position with guide roller 4 and is parallel with guide roller 4, makes hair brush roller 3 and guide roller 4 tangential, will The air suction nozzle 5 is installed vertically so that the bottom end of the air suction nozzle 5 is positioned at the tangent place between the guide roller 4 and the brush roller 3, and the top of the air suction nozzle 5 is connected to the air outlet of the blower fan A8 through a pipeline. There is a water tank 2, and the water tank 2 is installed horizontally and kept parallel ...

Embodiment 2

[0021] Embodiment 2: On the basis of the structure of Embodiment 1, a water pump is provided, and the water tank 2 is provided with a water inlet pipe and a water level switch. to an external water source.

[0022] Operation steps and working principle:

[0023] First, the base cloth passes through the lower suction pipe 1, and the cloth surface blocks the suction groove, which will generate a relatively large negative pressure suction force on the cloth surface, resulting in a good dust collection effect.

[0024] Then, after the base fabric has been sucked once, the base fabric is transported to the brush roller 3 by the guide roller 4. If there is any foreign matter embedded in the cloth surface, it will be cleaned again after being scraped by the brush roller 3, and a part of it will be cleaned by the suction port. Suck away, the other part is taken away by the brush roller 3, and when the brush roller 3 passes through the water tank 2, the remaining foreign matter sinks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com