Air-aspiration type manipulator for diamond inlaying and pasting industrial robot

An industrial robot, air-suction technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of high cost, complicated control system structure and program design, etc., to achieve a simple structure, expand the applicable environment, and facilitate future cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

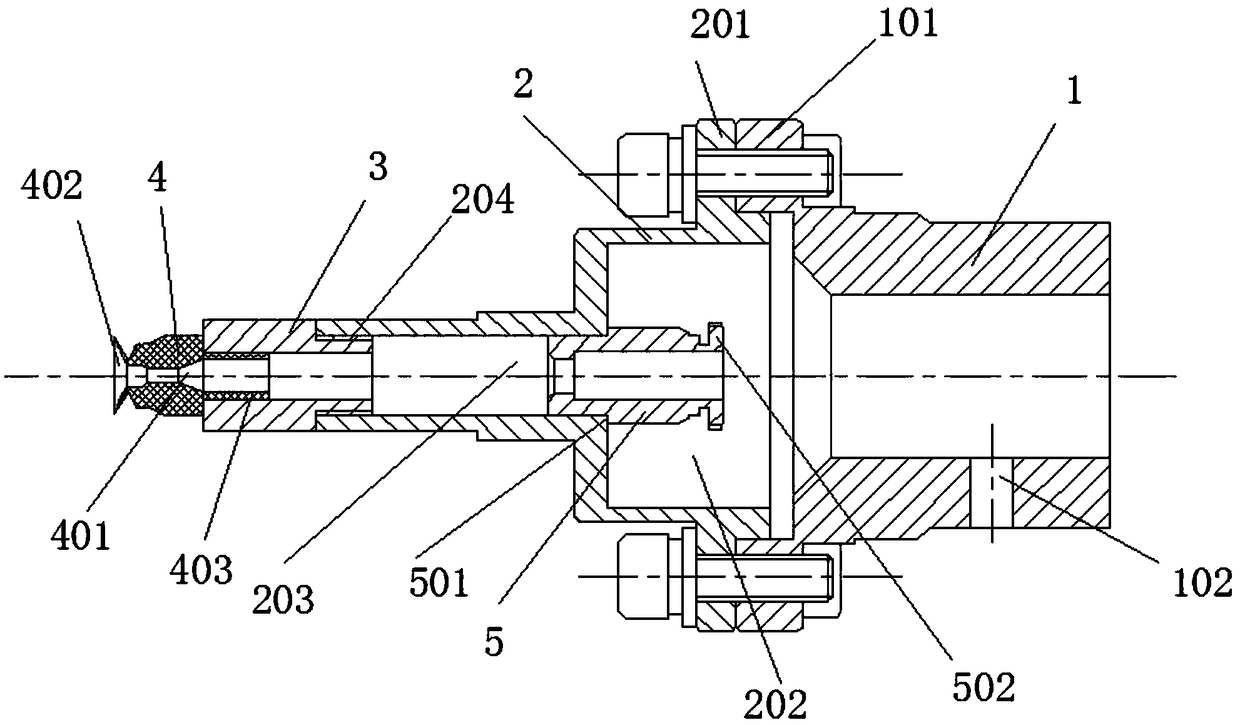

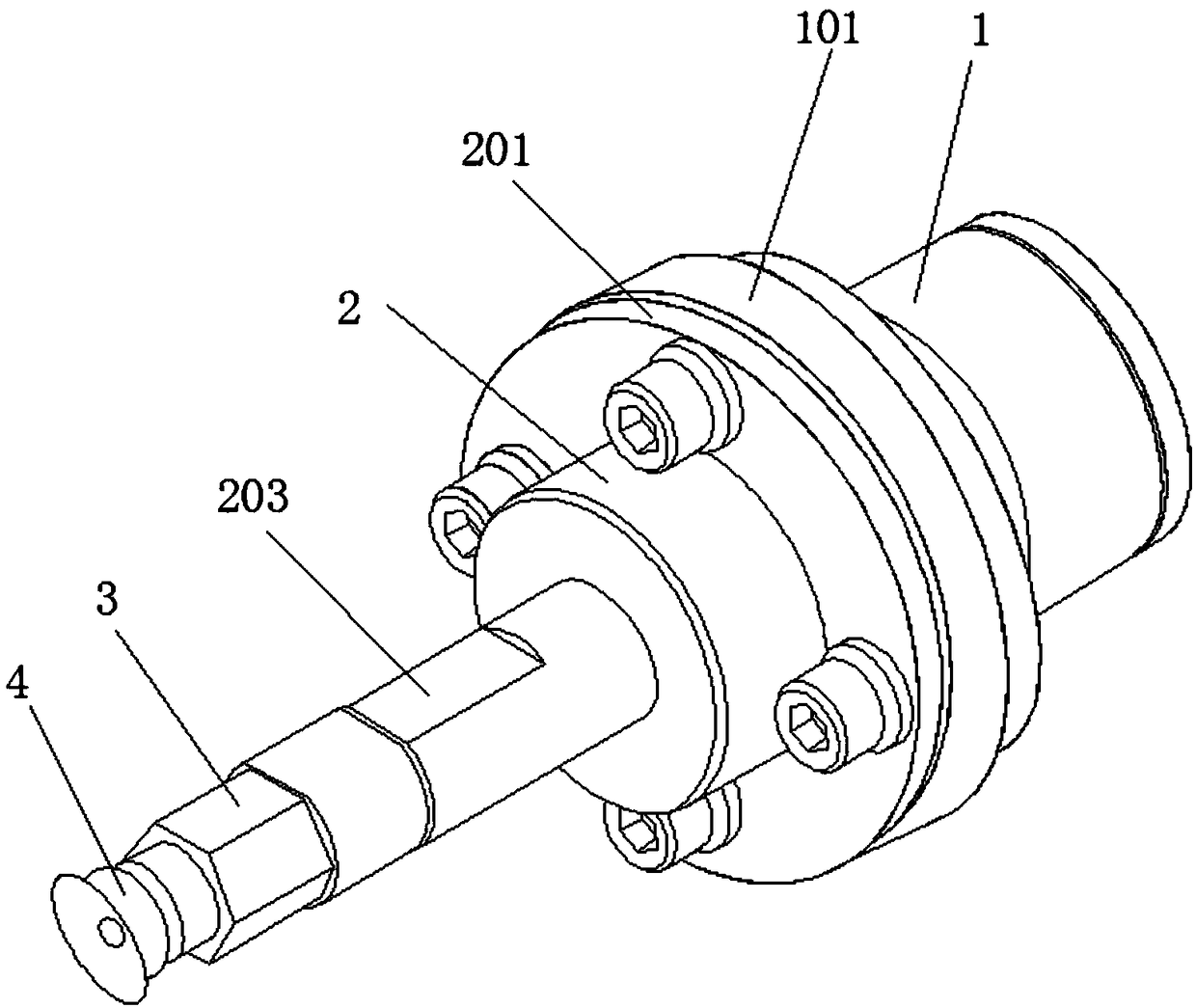

[0017] Attached below Figure 1-3 Specific examples of the present invention are described.

[0018] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. In the following embodiments, those related to the control circuit are conventional control methods unless otherwise specified. The components used in the following examples are commercially available unless otherwise specified.

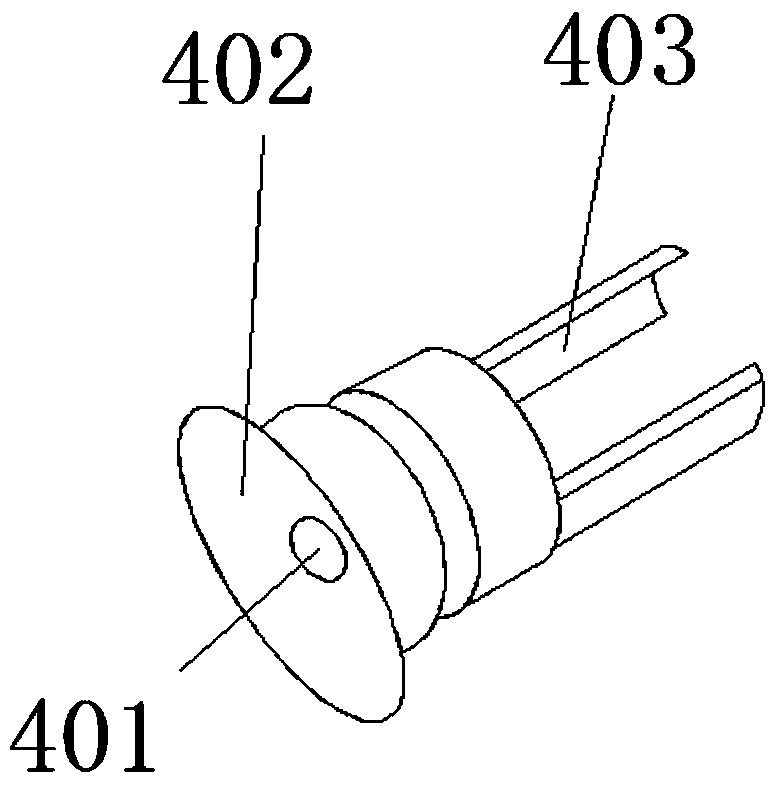

[0019] The air-suction manipulator used for diamond-studded and drill-attached industrial robots has a mounting pipe seat 1, a variable-diameter stepped pipe 2, an extension pipe 3 and a suction cup 4 for the execution end of the diamond-studded and drill-attached industrial robot air-suction manipulator. Characterized by: such as figure 1 As shown, the installation pipe seat 1 is made with a robot flange connection ring I101 protruding outward, and is coaxially tightened by the robot flange connection ring I101 and the robot f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com