Soldering flux supply mechanism for substrate ball mounter

A technology of flux and ball mounting, applied in the field of flux supply mechanism of substrate ball mounting machine, can solve the problems of corroding the flux supply mechanism, reducing the service life, and inability to adjust the thickness of the flux, and achieves the effect of convenient cleaning and corrosion prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

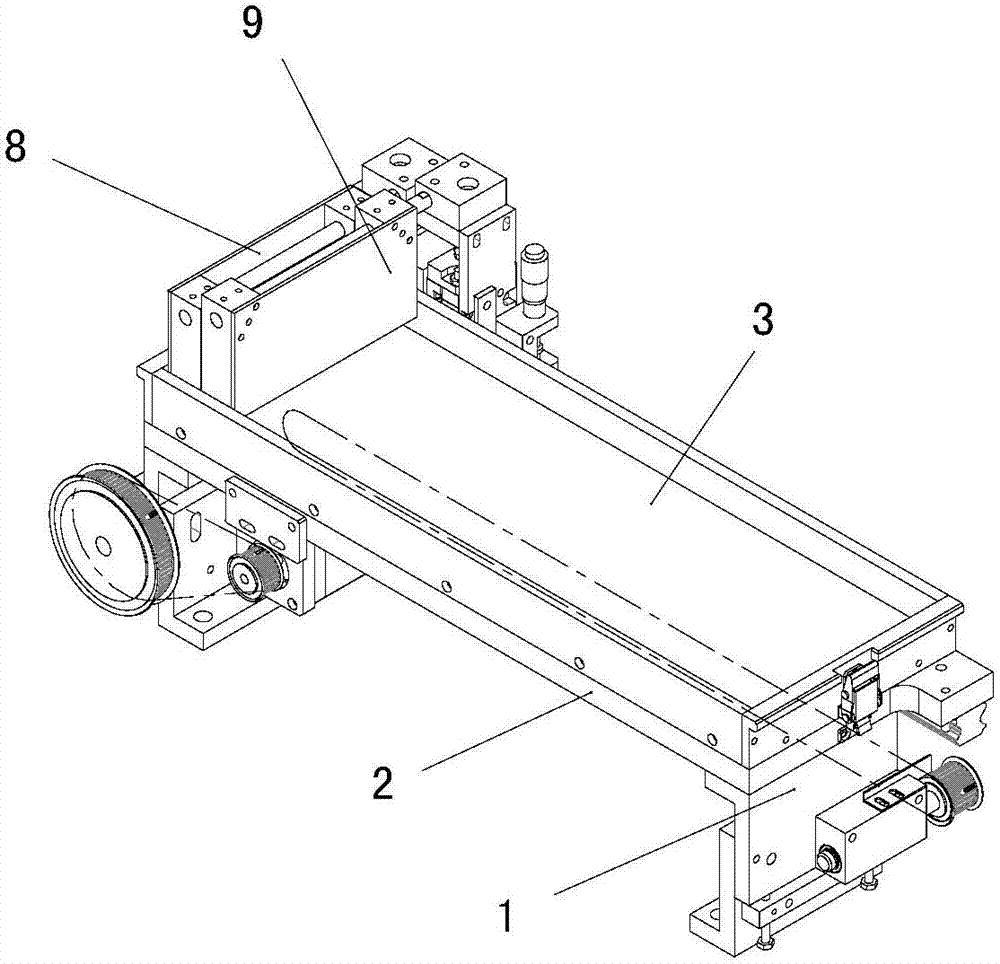

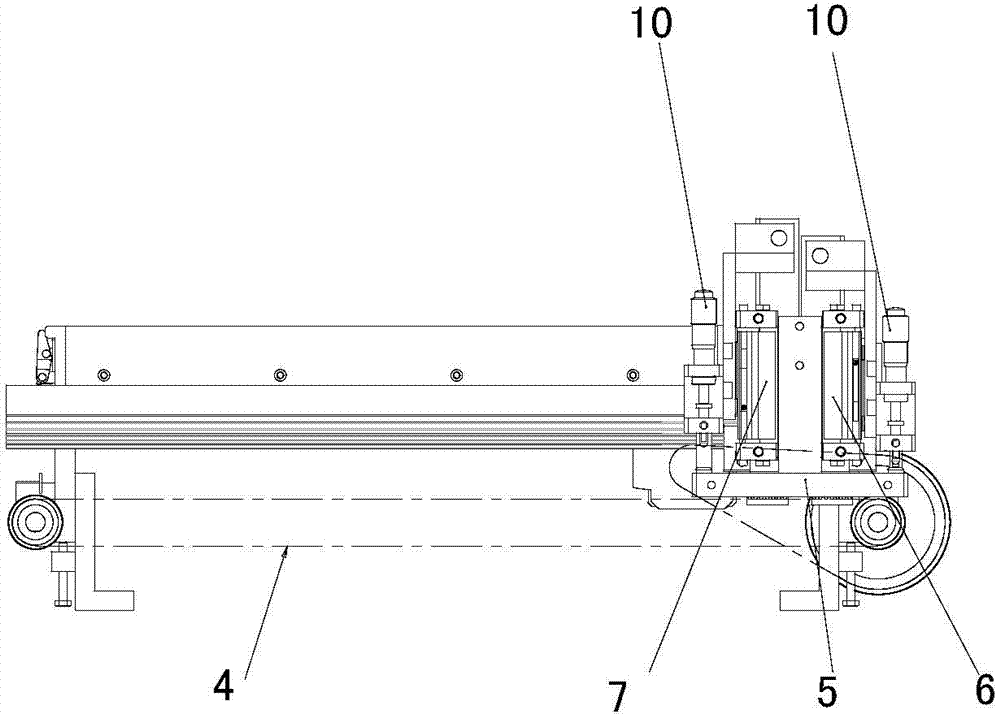

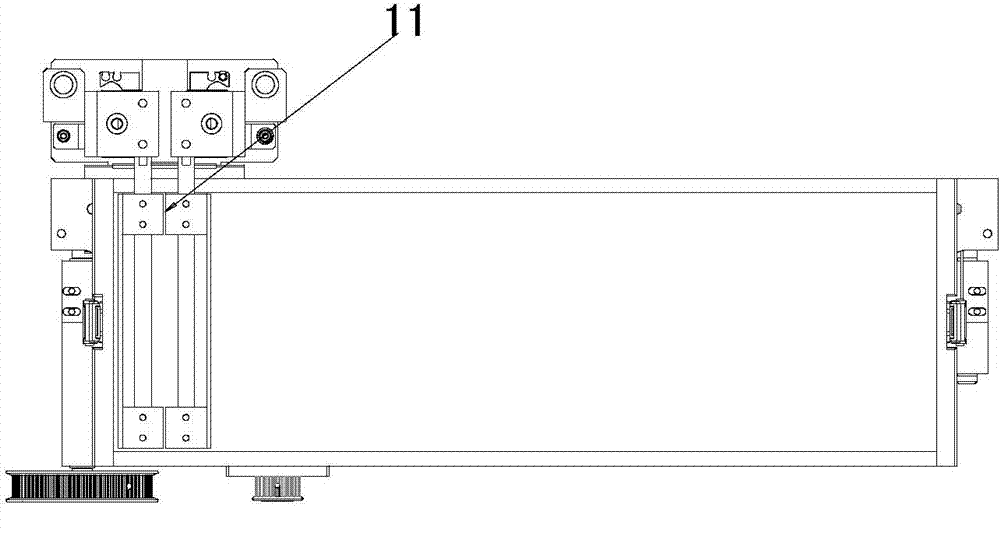

[0020] see figure 1 , figure 2 , image 3 , The flux supply mechanism of the substrate ball planting machine of the present invention includes a bottom bracket, a glue supply mechanism installed above the bottom bracket, a power mechanism installed below the bottom bracket, and a glue scraping mechanism installed on the power mechanism.

[0021] The bottom bracket includes two support plates 1 and a support platform 2 erected on the two support plates.

[0022] The glue supply mechanism includes a glue supply box 3; the glue supply box is installed on the support platform 2.

[0023] The power mechanism includes a motor and a transmission belt 4, and the power mechanism is installed on two support plates 1.

[0024] The squeegee mechanism includes a squeegee base plate 5 , a left squeegee cylinder 6 , a right squeegee cylinder 7 , a left squeegee 8 and a right squeegee 9 . The squeegee base plate 5 is installed on the transmission belt 4 of the power mechanism and can rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com