CNC Welding Bed for Realizing NC Welding of Plane Convex Weld

A convex profile and flat technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lack of real-time adjustment mechanism of welding torch, unable to meet the requirements of curved seam welding process, etc., to meet the welding process requirements. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0014] Plane convex profile definition: such as Figure 5 As shown, a contour line V on the plane, if there is a point O on the plane, and any ray S is made on the plane through point O, if any ray S has at most one intersection point with the contour line V, then the contour line V is called a plane convex profile. It is called the center of gyration of the plane convex profile at point O. The straight line passing through O and perpendicular to the plane of the contour line V is called the axis of rotation. A planar convex profile may have an infinite number of centers of revolution and therefore an infinite number of axes of revolution at the same time.

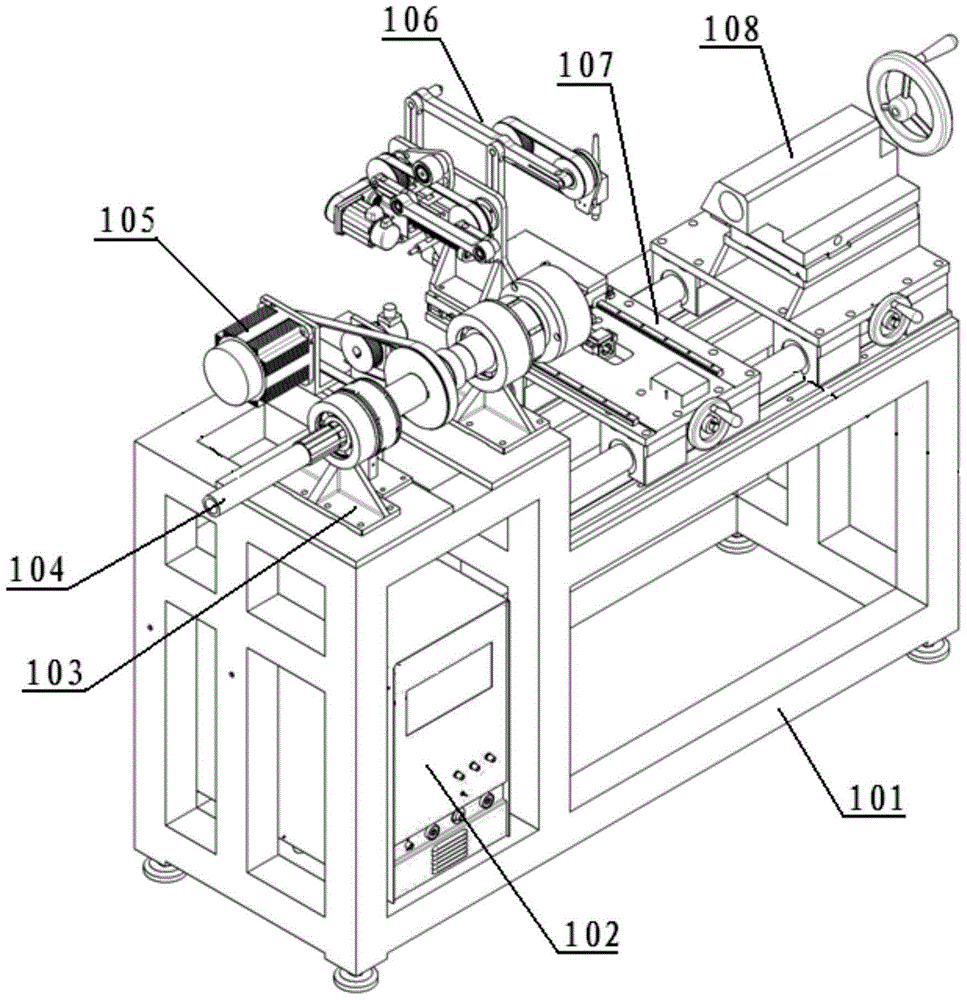

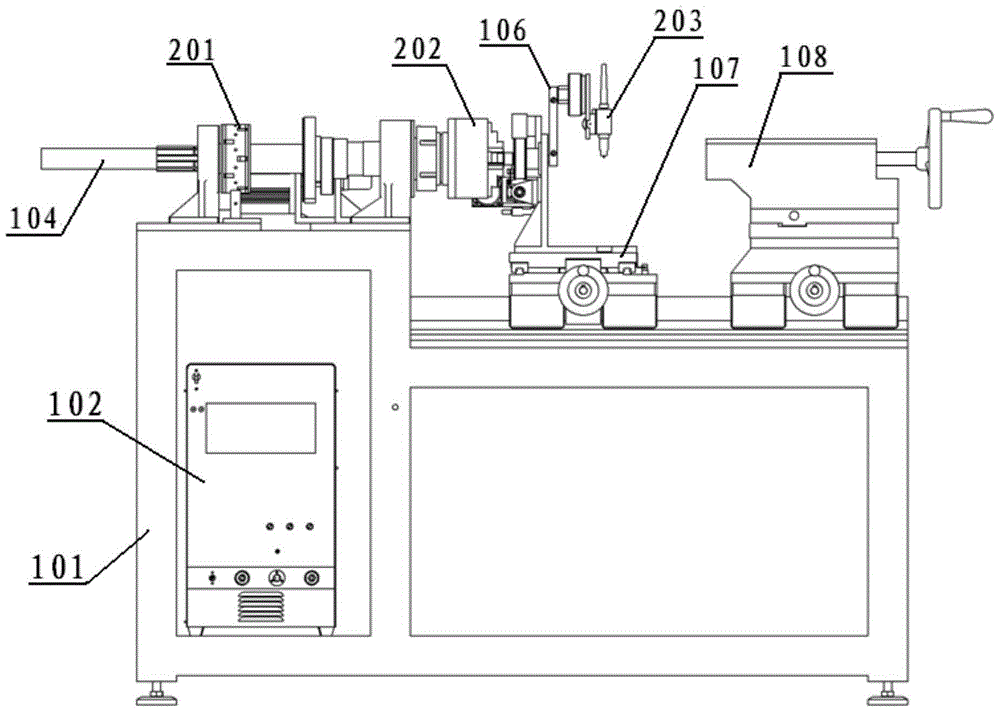

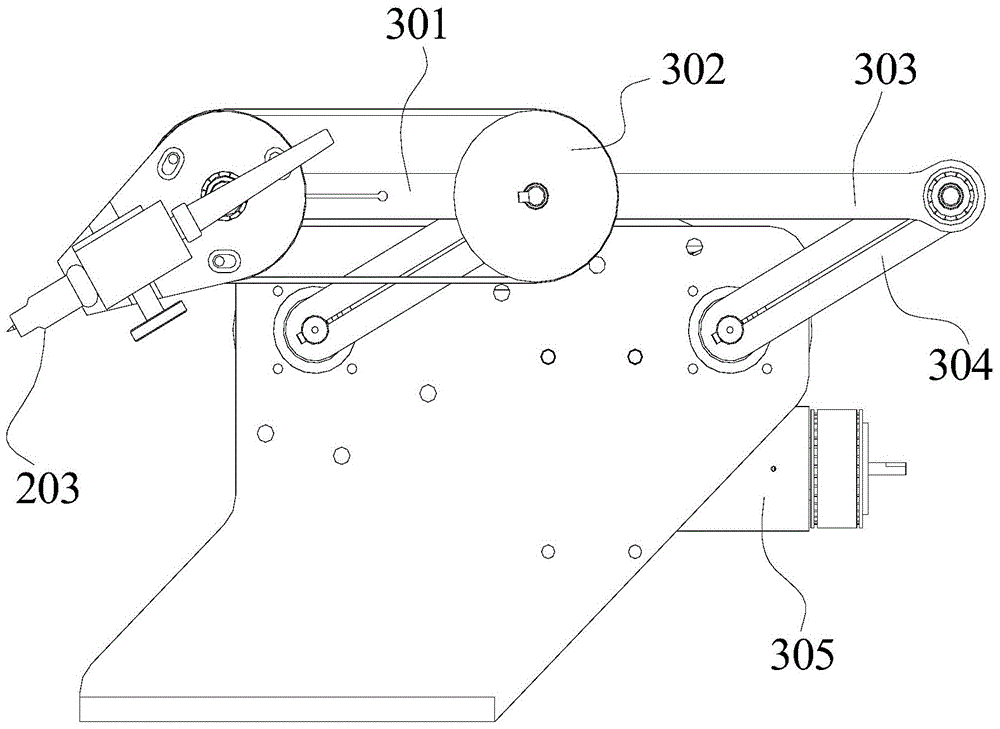

[0015] Such as figure 1 with figure 2 Shown is a numerically controlled welding bed for realizing numerically controlled welding of planar convex contour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com