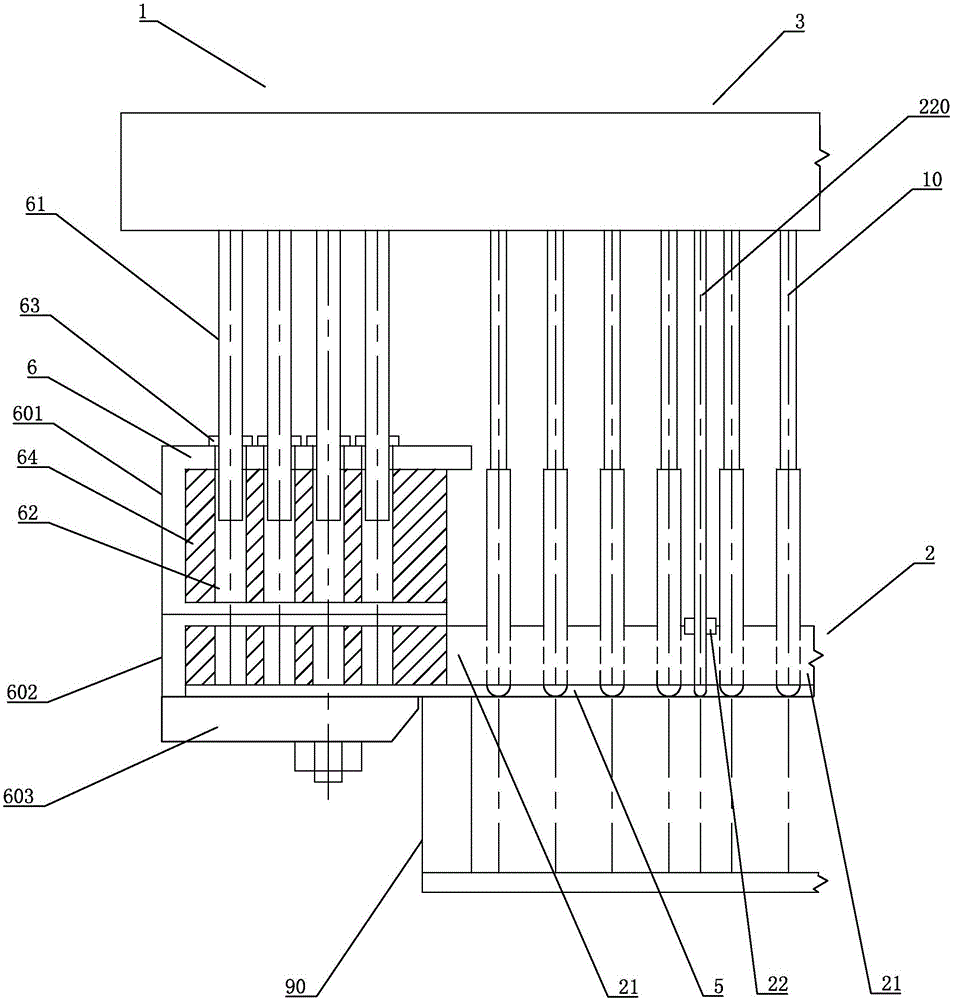

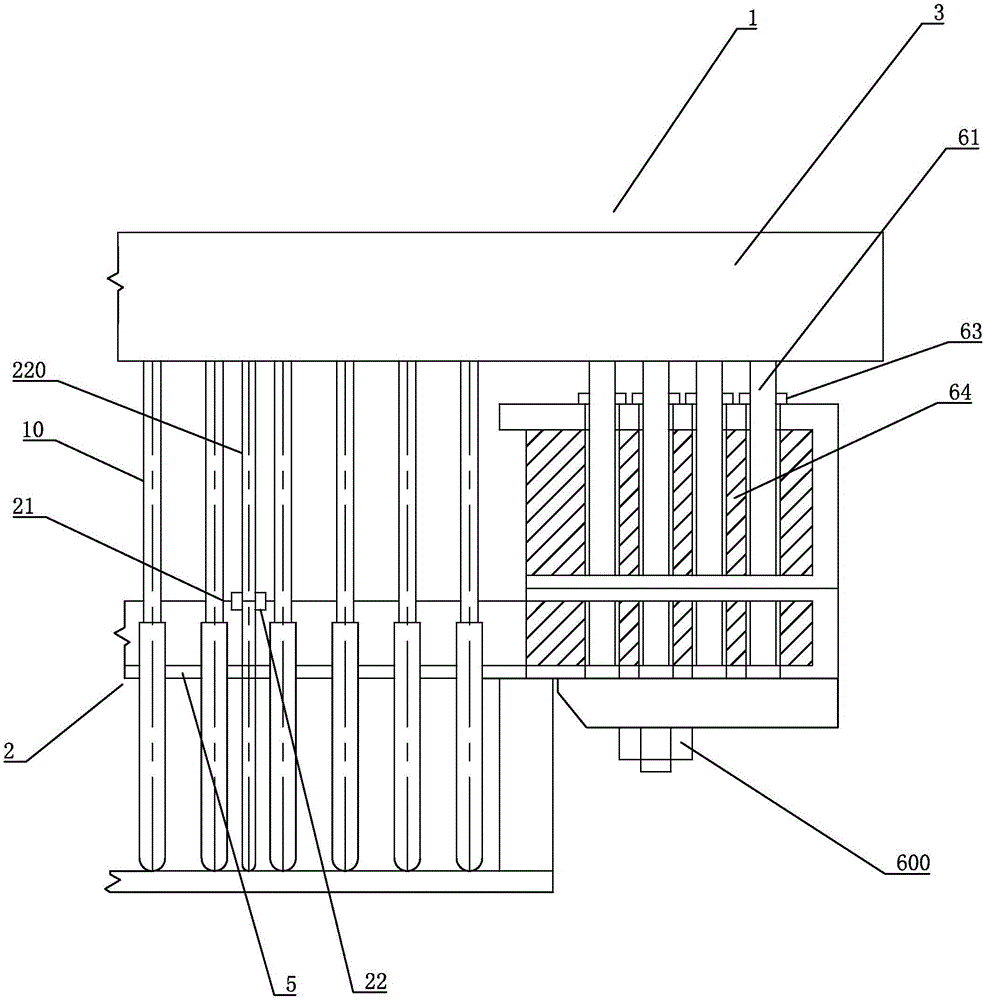

Plug-in hole-forming mold and device and automatic manufacturing method for porous brick

A technology for forming holes and moulds, applied in the direction of moulds, manufacturing tools, ceramic molding machines, etc., can solve problems such as low production efficiency and unsatisfactory effects, and achieve the effects of uniform distribution, uniform force, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

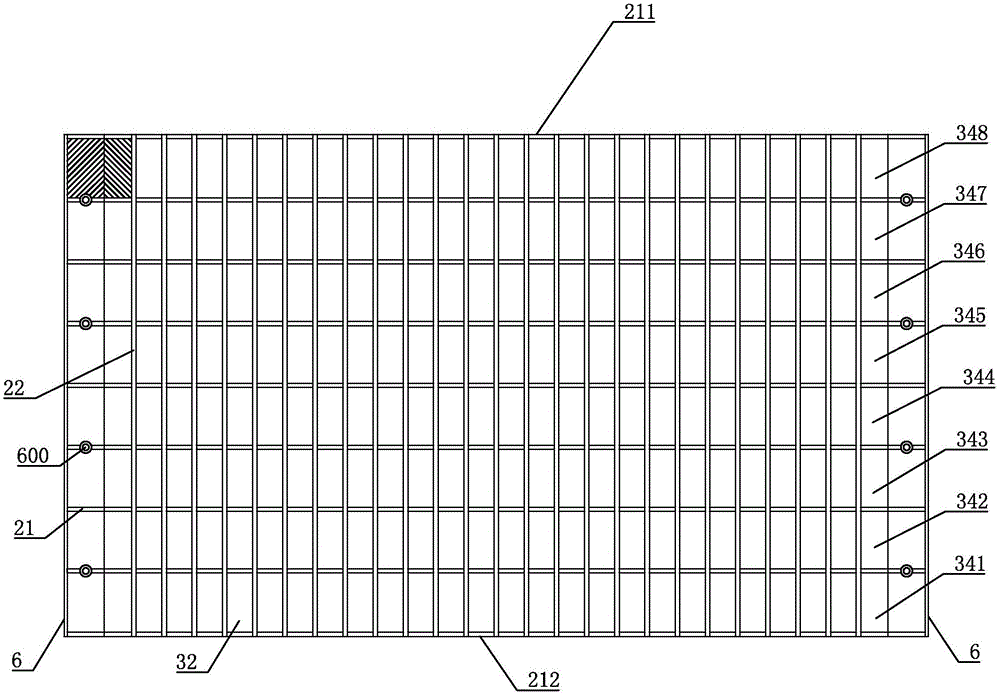

[0050] Taking the production of porous bricks of 240×115×90mm as an example, the implementation process of the hole-forming method of the present invention will be described in detail. For a porous brick with a certain hollow rate and a certain brick surface area, the more rows of holes, the smaller the holes. For example, taking a circular hole as an example, when the hollow rate is about 35%, for a porous brick of 240×115×90mm, when the number of rows of holes increases from 5 rows to 13 rows, the diameter of the holes will decrease from 16mm to 6mm, the number of holes increased from 48 holes to 332 holes. But the smaller the hole, the more rows of holes, and the more difficult it is to produce.

[0051] Based on the principle of from easy to difficult, this embodiment is to produce a batch of 8 rows and 26 rows of 208 porous bricks. The aperture of the round hole on each porous brick is 12mm, the hollow rate is 36%, 25 rows, An example of a total of 88 round holes in 7 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com