Four-cavity mould plastic line pipe automatic packaging device

An automatic packaging, one-mold four-out technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of wasting manpower, counting errors, and increasing quality management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the embodiment of accompanying drawing, the present invention is described in further detail:

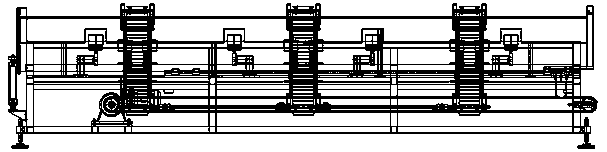

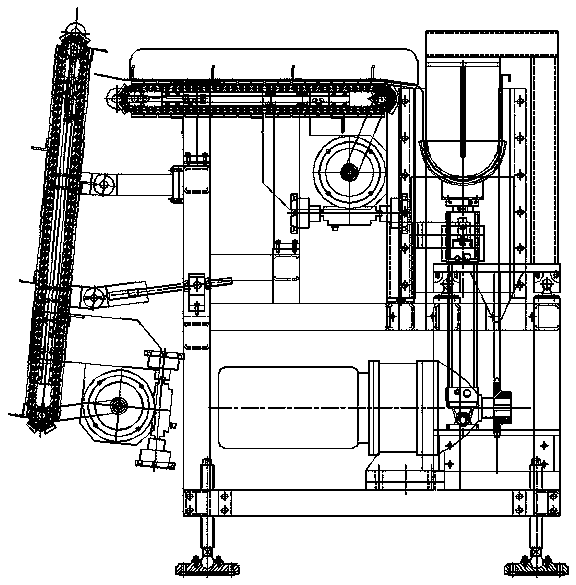

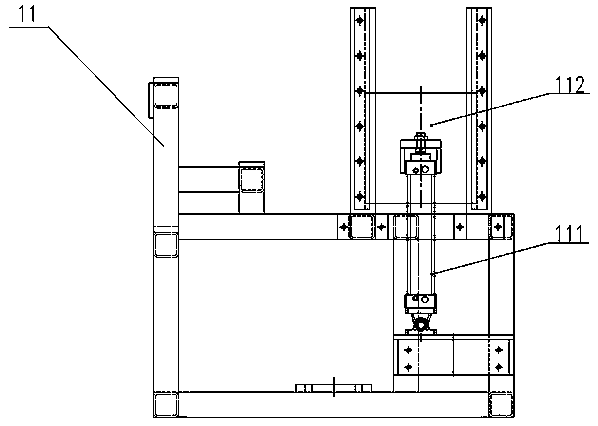

[0037] Such as figure 1 As shown in -24, the automatic packaging device for plastic linear pipes with one mold and four outlets is composed of automatic counting and stacking unit 1, automatic binding unit 2, traction and conveying unit 3, automatic edge banding and cutting unit 4 and control unit 5. The automatic counting and stacking unit 1 is installed at the tail of the pipe production line, the automatic binding unit 2 is installed at the rear end of the automatic counting and stacking unit 1, the traction and conveying unit 3 is installed at the rear end of the automatic binding unit 2, and the automatic The edge sealing and cutting unit 4 is installed at the rear end of the traction and conveying unit 3 . The control unit 5 is a movable device, installed near the production line and convenient for operation. The automatic counting and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com