Bidirectional walking mechanism for crossed track shuttle

A walking mechanism and two-way walking technology, which is applied in the direction of conveyors, mechanical conveyors, storage devices, etc., can solve the problems that are not suitable for small shuttle vehicles and large vehicle volume, and achieve small footprint and compact device structure , the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

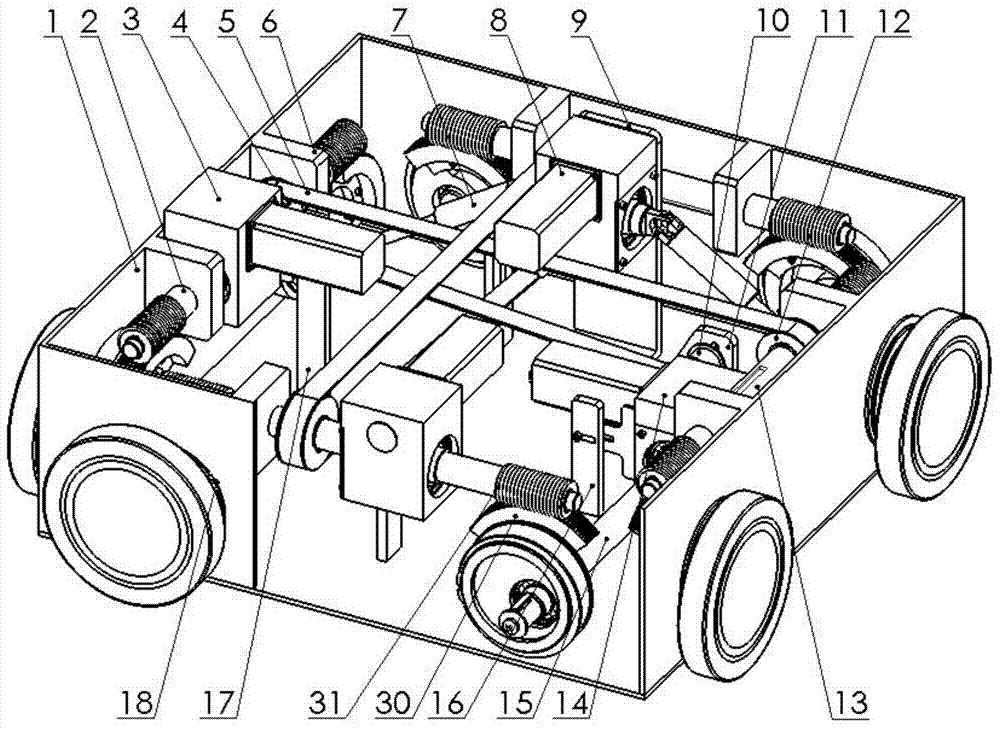

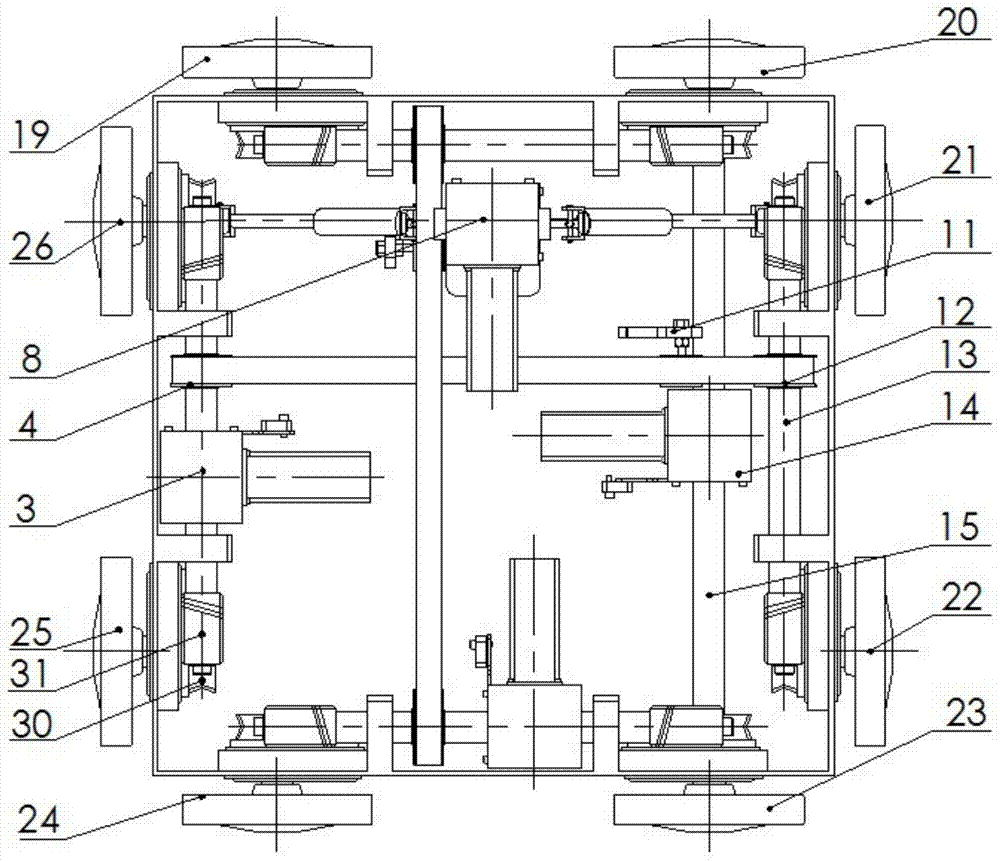

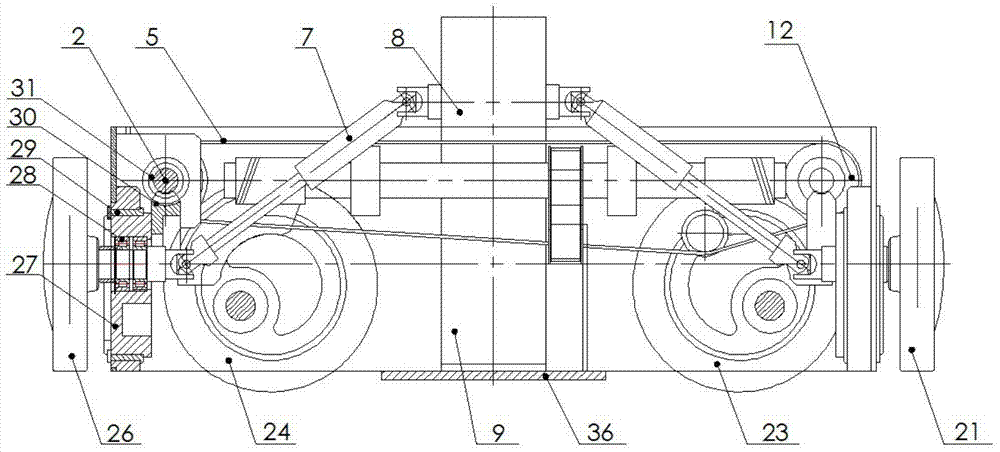

[0027] Describe the specific implementation process of the present invention in detail below in conjunction with accompanying drawing, as Figure 1-8 shown.

[0028] The invention is composed of a car body, a lifting mechanism, a longitudinal traveling mechanism, a transverse traveling mechanism, an electric appliance storehouse and an electrical system.

[0029] Car body 1 is the basis for installing each mechanism, and is a rectangular frame that is welded or connected with bolts by four side plates, and two bearing housing holes 18 are all arranged on each side plate, and the inside of each side plate (i.e. Towards the inner side of the car body) a worm shaft support seat 6 is installed, and a crossbeam 36 is installed at the bottom of the frame ( figure 1 ).

[0030]There are two groups of lifting mechanisms with the same structure, consisting of a reduction servo motor 3, a worm shaft 2, 13, a worm wheel 30, an eccentric disc 27, a sliding bearing seat 29, a rolling bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com