Mine gas bundle pipeline monitoring system

A monitoring system and beam tube technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficulty in finding pipeline fault points, low overall efficiency, safety accidents, etc., and achieve improved usability, reliability, and accuracy The scope of pipeline faults and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

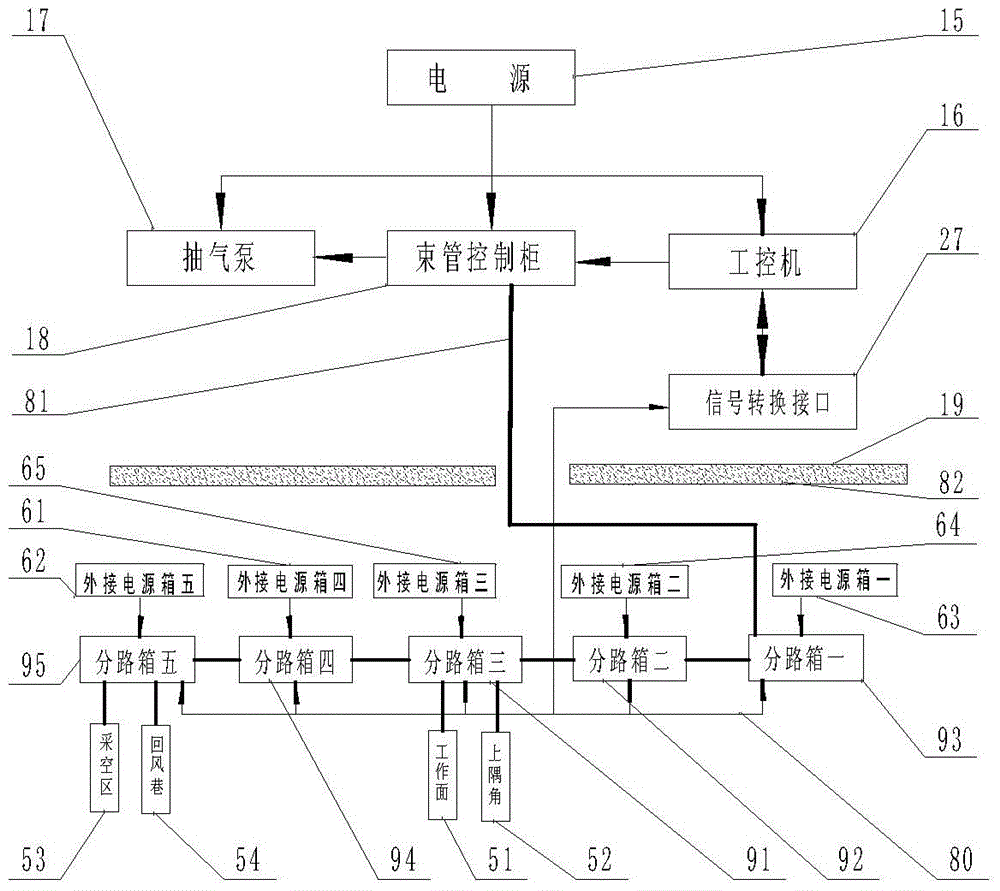

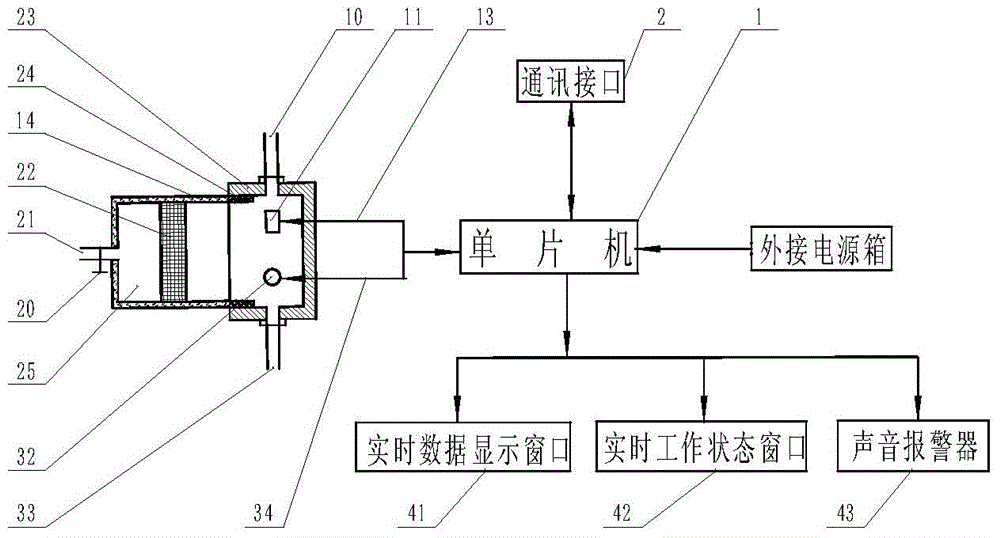

[0030] For a first example, see figure 1 , figure 2 , a mine gas bundle pipe pipeline monitoring system, which includes a power supply 15 electrically connected to an air pump 17 on the ground 19, a PLC programmable control bundle pipe control cabinet 18, and an industrial computer 16, characterized in that: the industrial computer 16 is electrically connected to signal conversion Interface 27, PLC programmable control beam tube control cabinet 18 tubes connected underground 82 equipped with external power box 1 63, external power box 2 64, external power box 3 65, external power box 4 61, external power box 5 62 Branch box one 93, branch box two 92, branch box three 91, branch box four 94, branch box five 95, signal conversion interface 27 is connected to the communication interface 2 of each branch box by system communication line 80. The number of branch boxes and the number of external power supply boxes are determined according to actual needs.

[0031] Wherein: the sh...

no. 2 example

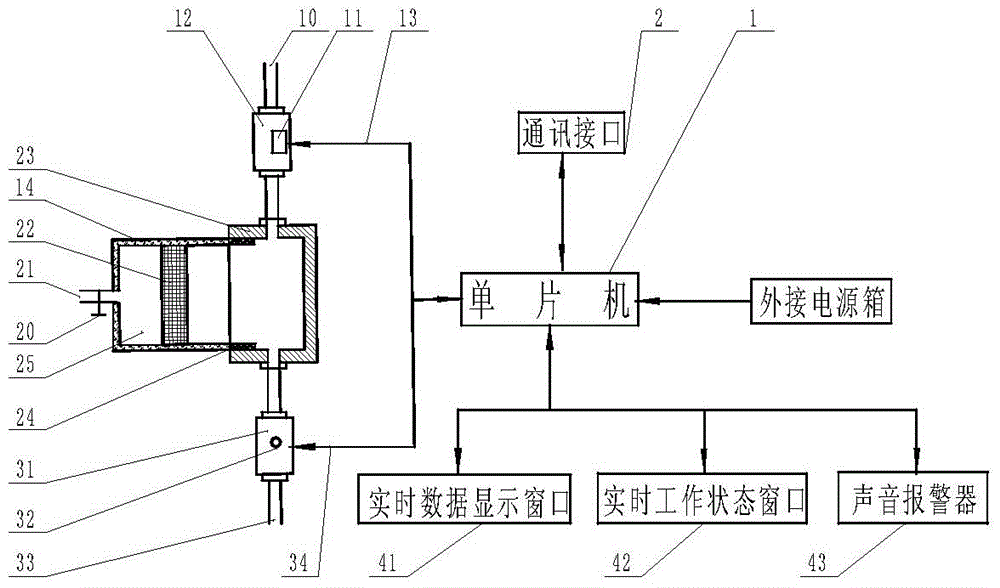

[0036] For a second embodiment, see figure 1 , image 3 , a mine gas bundle pipe pipeline monitoring system, which includes a power supply 15 electrically connected to an air pump 17 on the ground 19, a PLC programmable control bundle pipe control cabinet 18, and an industrial computer 16, characterized in that: the industrial computer 16 is electrically connected to signal conversion Interface 27, PLC programmable control beam tube control cabinet 18 tubes connected underground 82 equipped with external power box 1 63, external power box 2 64, external power box 3 65, external power box 4 61, external power box 5 62 Branch box one 93, branch box two 92, branch box three 91, branch box four 94, branch box five 95, signal conversion interface 27 is connected to the communication interface 2 of each branch box by system communication line 80. The number of branch boxes and the number of external power supply boxes are determined according to actual needs.

[0037] Wherein: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com