Engine Exhaust Brake Butterfly Valve

An exhaust brake and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of affecting the flexibility of valve opening and closing, poor elasticity of the sealing ring, increasing engine energy loss, etc., and achieve high promotion. Application value, simple structure, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

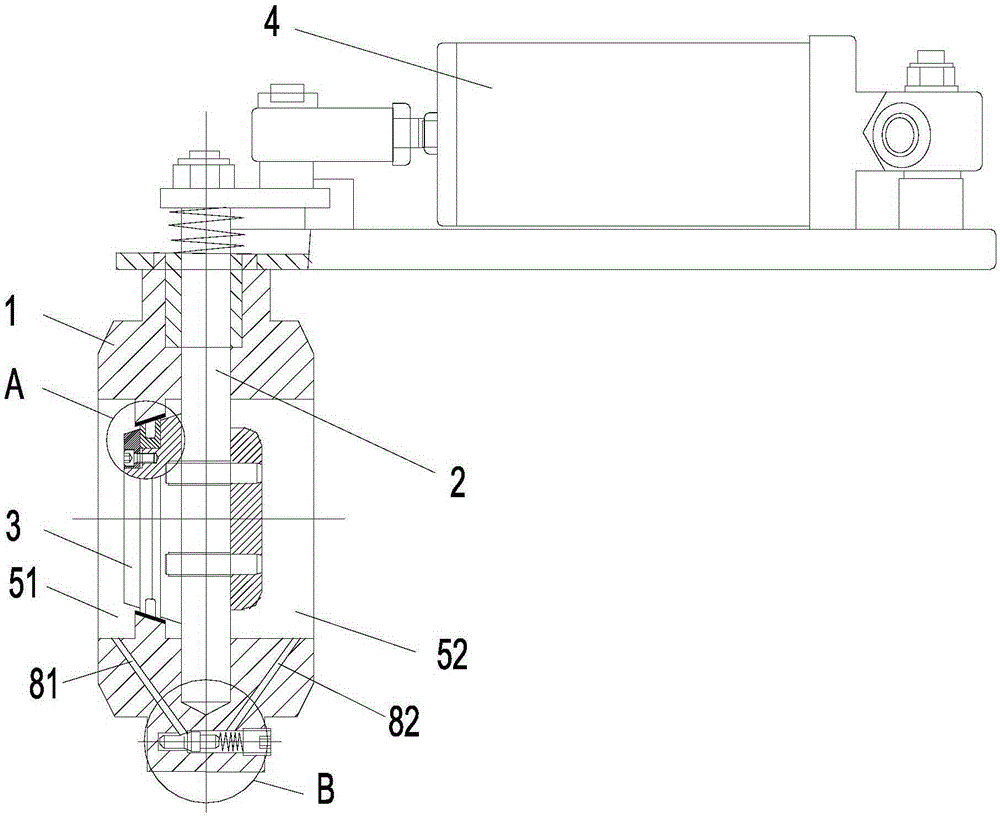

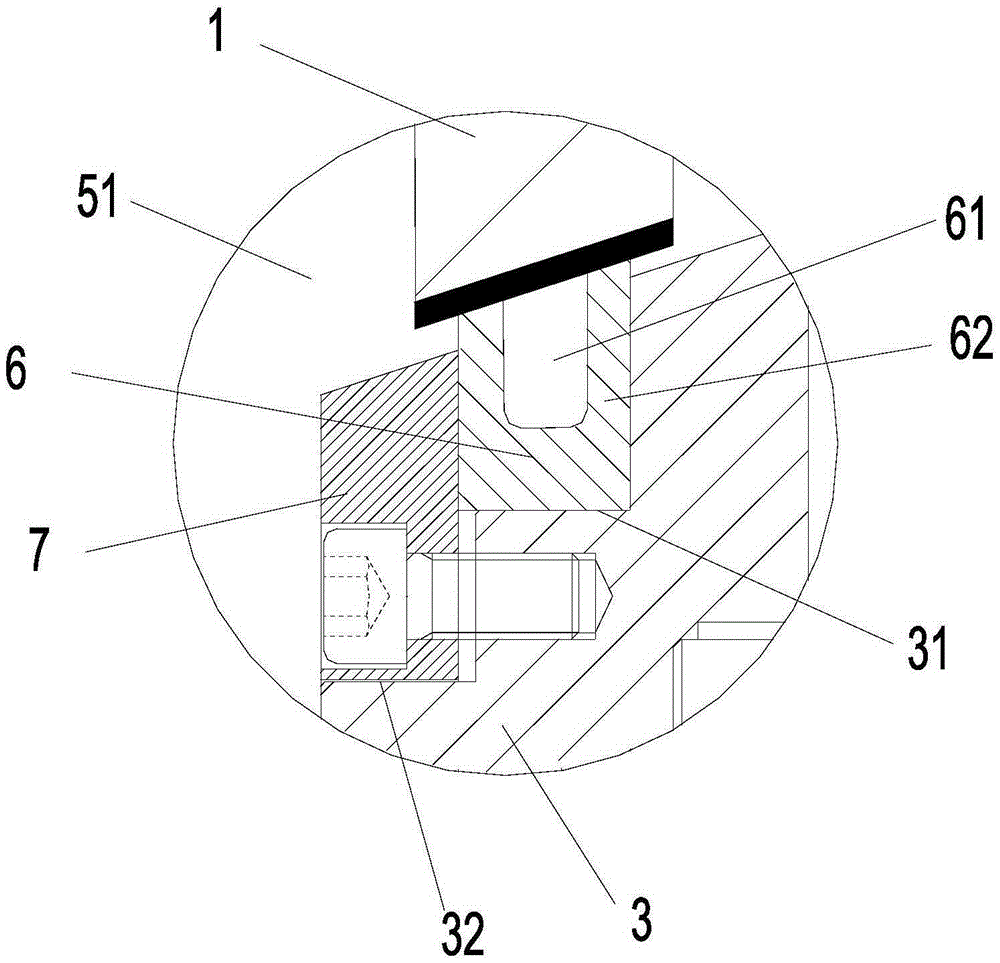

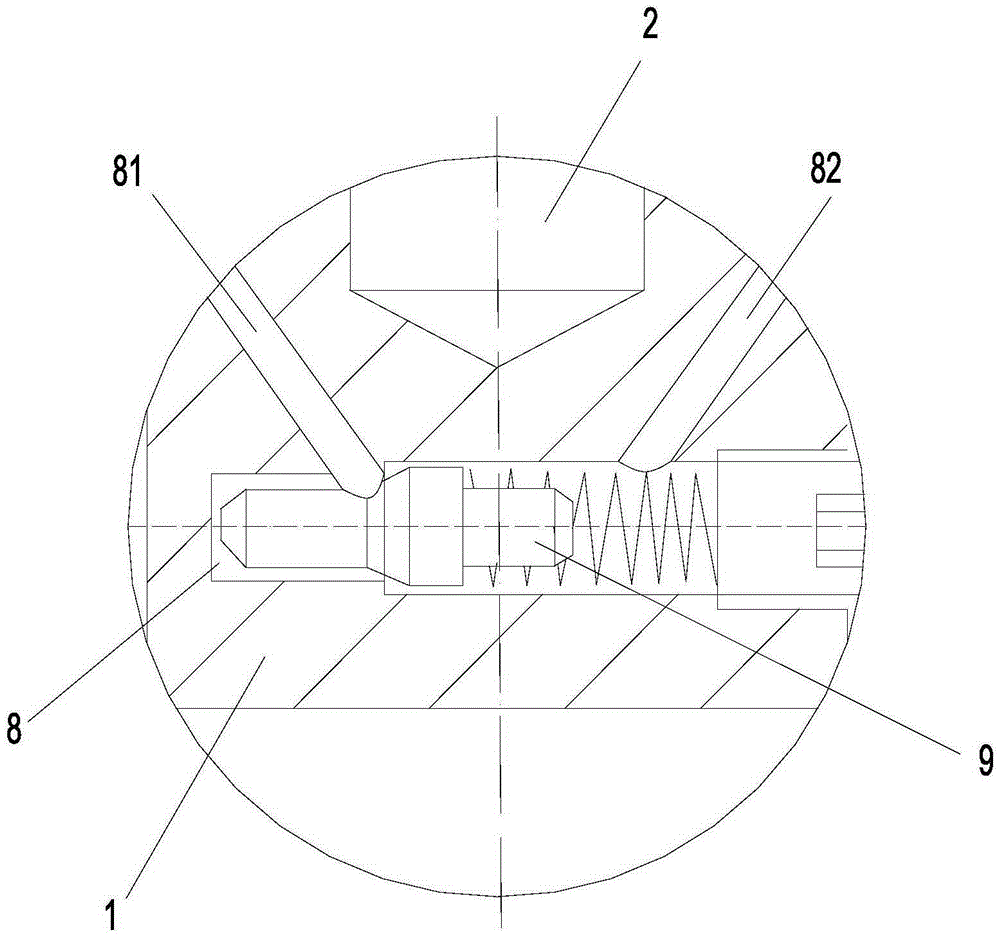

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The magnified image at A in the middle, image 3 for figure 1 The enlarged view at B is shown in the figure: the engine exhaust brake butterfly valve of this embodiment includes a valve body 1, a rotating shaft 2, a valve plate 3 and a power mechanism 4, and the valve plate 3 is fixed by the rotating shaft 2 In the inner cavity of the valve body 1, the valve plate 3 is connected to the power mechanism 4, and the power mechanism 4 drives the valve plate 3 to turn over in the inner cavity around the rotating shaft 2, When the valve plate 3 is closed, the inner cavity is divided into an intake cavity 51 and an exhaust cavity 52, and the valve plate 3 is fixed with a sealing ring 6 for forming a sealing connection with the cavity wall of the inner cavity, so The sealing surface between the sealing ring 6 and the inner cavity wall is staggered by the hollow part 61 on the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com