Large-displacement integrated rotor and stator pair cycloid hydraulic motor

A technology of hydraulic motor and rotating stator is applied in the field of cycloid hydraulic motor and integral rotating stator pair cycloid hydraulic motor, which can solve the problems of unfavorable flatness at both ends, affecting the comprehensive performance of the motor, and difficulty in processing. The dimensional accuracy and position accuracy are easy, the theoretical position accuracy is easy to guarantee, and the overall assembly is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

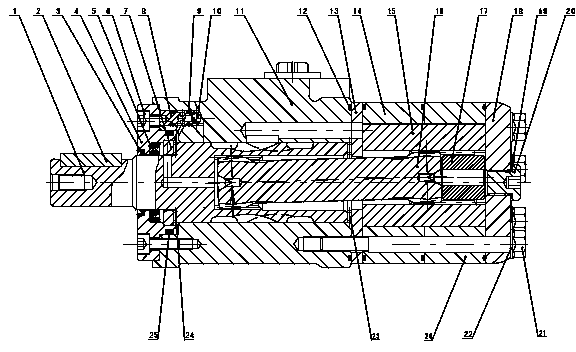

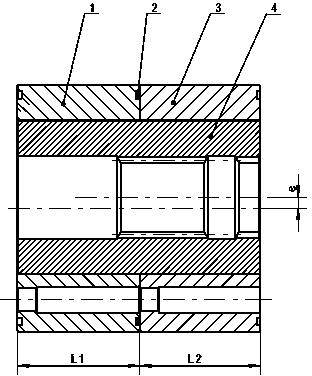

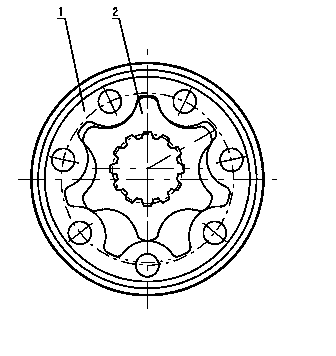

[0026] The large-displacement integrated rotor-stator pair cycloidal hydraulic motor of this embodiment has compact radial dimensions, and the length of the integral rotor-stator pair is greater than 65mm, such as the nominal displacement of the motor is 630 or 740, etc., and its structure is as follows figure 1 As shown, it mainly includes output shaft 1, front cover 4, body shell 11, linkage shaft 16, spacer 13, front stator 14, rotor 15, rear stator 26, rear cover 18, etc. The stator is spliced by two split parts, and the two split stators are sealed by an O-ring, and the rotor is a whole. The assembly structure of the integral rotor stator pair is as follows: figure 2 As shown in the figure, the front stator 1, O-ring 2, front stator 3, and rotor 4 are shown in the figure, and the meshing diagram of the integral rotor stator pair is shown in image 3 As shown, the stator 1 and the rotor 2 in the figure.

[0027] figure 1 The internal spline of the rotor 15 is a disco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com