Assembling device and assembling method for gearbox double-shaft assembly of tractor

A gearbox and tractor technology, which is applied to transmission parts, mechanical equipment, belts/chains/gears, etc., can solve problems that affect the quality of products, lack of falling guides, and the meshing surfaces of gears are prone to bumps and flaws, etc., to achieve The assembly process is fast, safe and reliable, the method is simple and easy, and the effect of avoiding cutting and scratching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

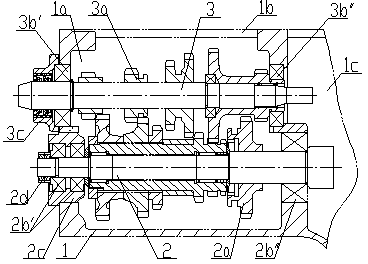

[0081] Depend on Figure 8 , Figure 9 As is known, a combination device for tractor gearbox biaxial assembly includes: a body assembly 9, two sets of guide assemblies 10, a positioning assembly 11, a lifting hook assembly 12 and a pre-installation assembly 13; wherein, in the body assembly On (9), there are positioning components (11), two sets of guide components (10) and lifting hook components (12) fixedly connected, that is, forming a "components fixedly connected as a whole".

[0082] Depend on Figure 10 , Figure 11 Known, a kind of assembly device that is used for tractor gearbox biaxial assembly, described body component 9, comprises: base body 14, long sleeve 15 and short sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com