Torsion bar type underground focus suitable for cased wells with any slope

A cased well and torsion bar technology, which is applied in the field of petroleum and geological exploration, can solve the problems of increased energy attenuation, increased overall size, and high energy consumption, achieving centralized and effective energy transmission, and improved reliability and safety , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

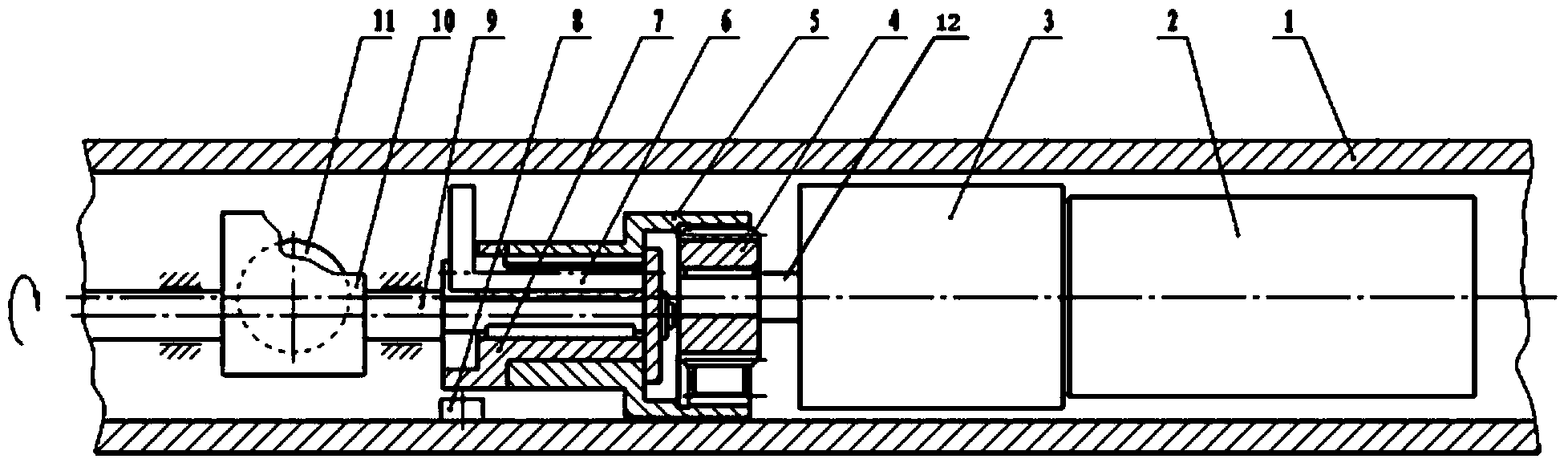

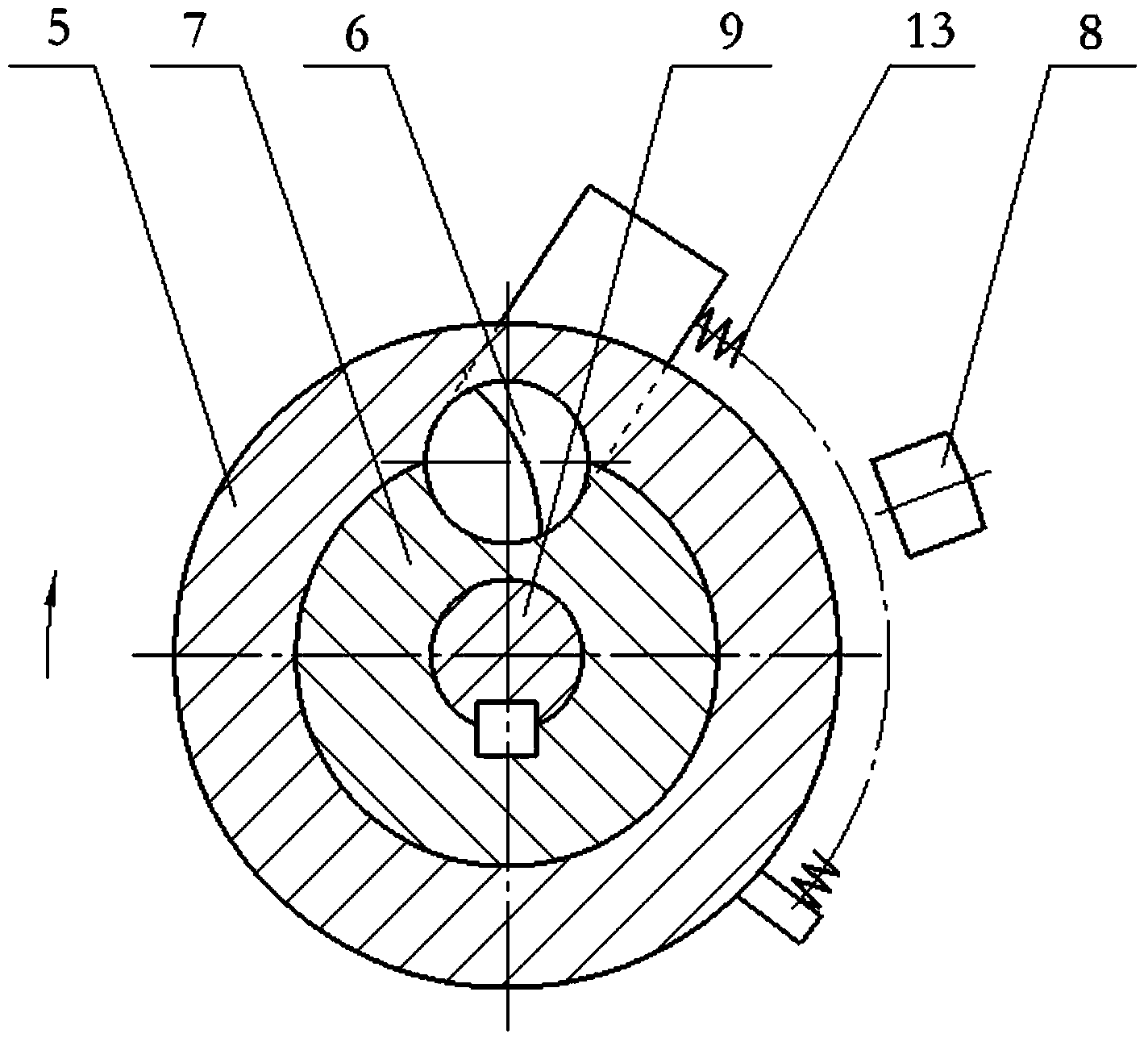

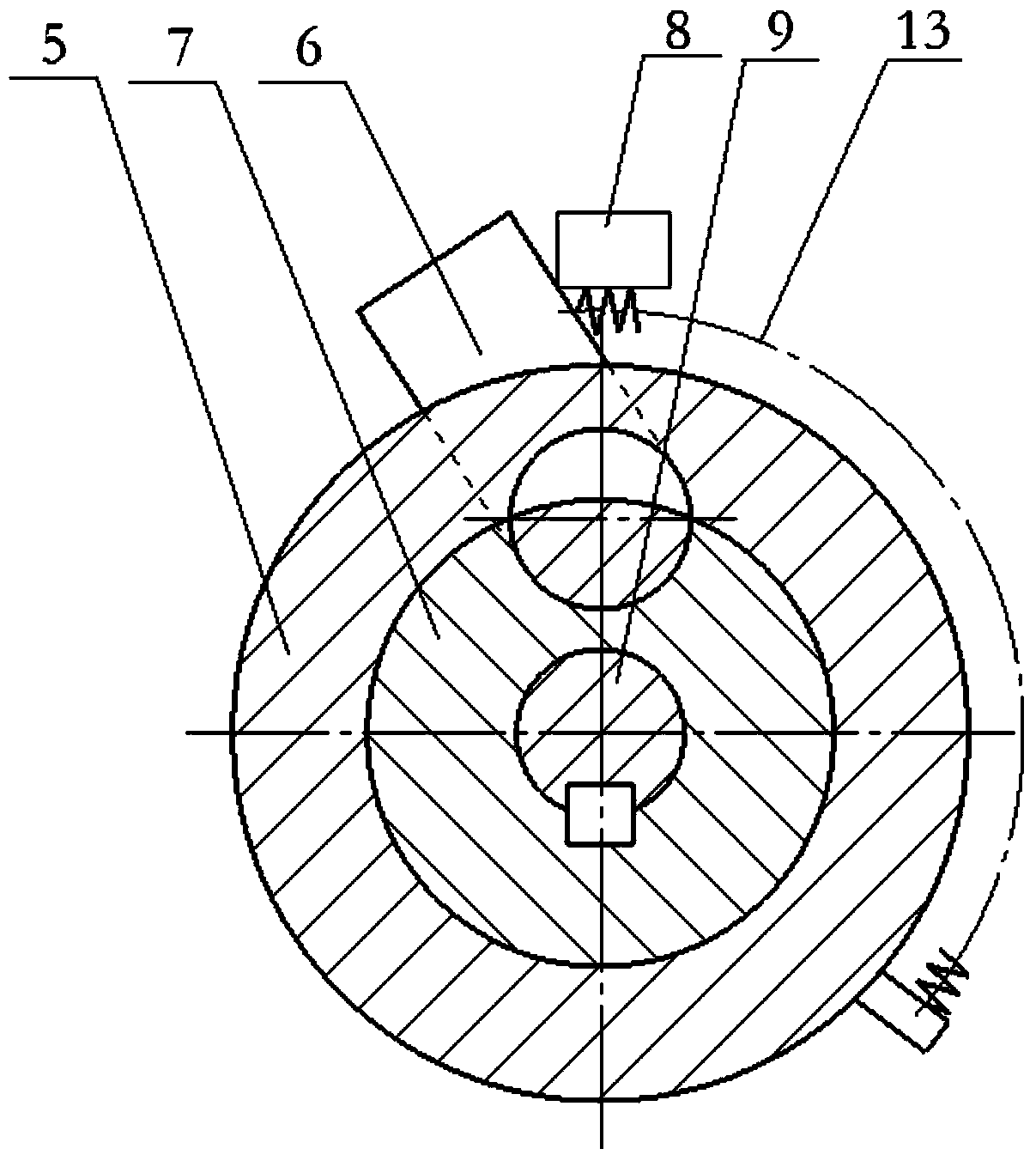

[0030] A torsion bar downhole seismic source suitable for cased wells with any inclination, including a casing 1, a motor 2, a reducer 3, a driving gear 4, a driven gear 5, a driving rod 6, a base 7, a stopper 8, and a torsion bar 9 , pendulum 10, anvil 11, transmission rod 12, extension spring 13 and spring eccentric 14; Motor 2, speed reducer 3, driving gear 4 are connected through transmission rod 12 successively; Driving gear 4 is internally meshed with driven gear 5; The corresponding part on the driven gear 5 and the base 7 has a semicircular slot hole, which forms a circular slot hole relatively, and the driving rod 6 is inserted into the circular slot hole; the driving rod 6 has an arc-shaped gap corresponding to the radian of the outer edge of the base The lever 6 is connected to the base 7 through the extension spring 13; the base 7 and the torsion bar 9 are connected by a key; the block 8 is fixed on the shell 1; the torsion bar 9 is fixedly connected to the pendulum...

Embodiment 2

[0033] A torsion bar downhole seismic source suitable for cased wells with any inclination, including a casing 1, a motor 2, a reducer 3, a driving gear 4, a driven gear 5, a driving rod 6, a base 7, a stopper 8, and a torsion bar 9 , pendulum 10, anvil 11, transmission rod 12, extension spring 13 and spring eccentric 14; Motor 2, speed reducer 3, driving gear 4 are connected through transmission rod 12 successively; Driving gear 4 is internally meshed with driven gear 5; The corresponding part on the driven gear 5 and the base 7 has a semicircular slot hole, which forms a circular slot hole relatively, and the driving rod 6 is inserted into the circular slot hole; the driving rod 6 has an arc-shaped gap corresponding to the radian of the outer edge of the base The lever 6 is connected to the base 7 through the extension spring 13; the base 7 and the torsion bar 9 are connected by a key; the block 8 is fixed on the shell 1; the torsion bar 9 is fixedly connected to the pendulum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com