Tire full-automatic code reading machine and code reading method thereof

A fully automatic, code-reading machine technology, which is applied in electromagnetic radiation induction, program control in sequence/logic controller, electrical program control, etc., to achieve clear images, improve labor efficiency, and save financial and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

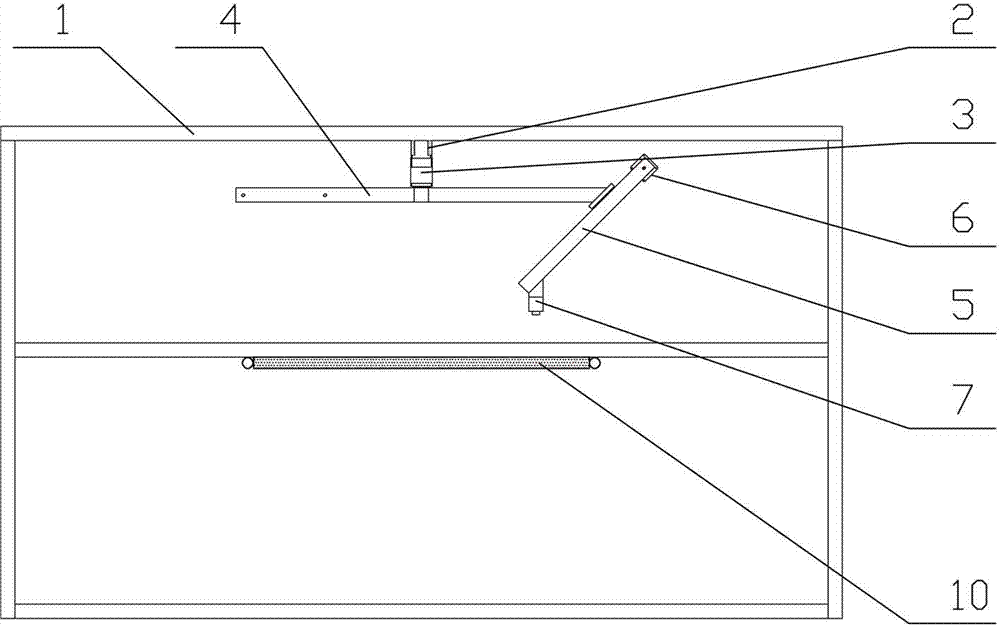

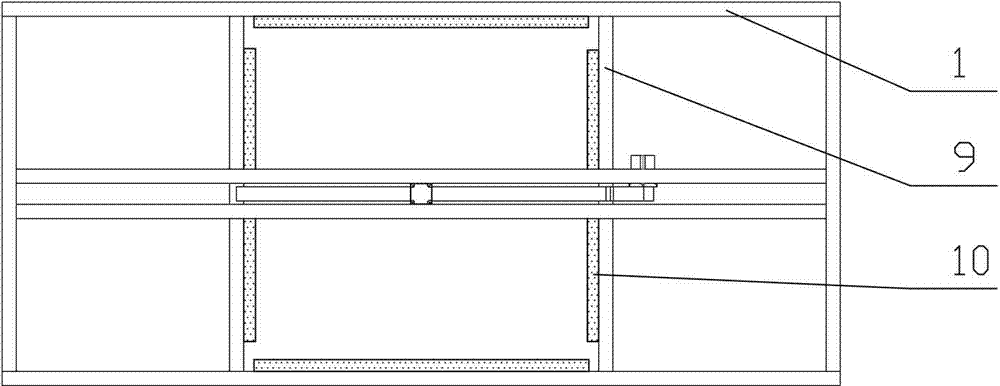

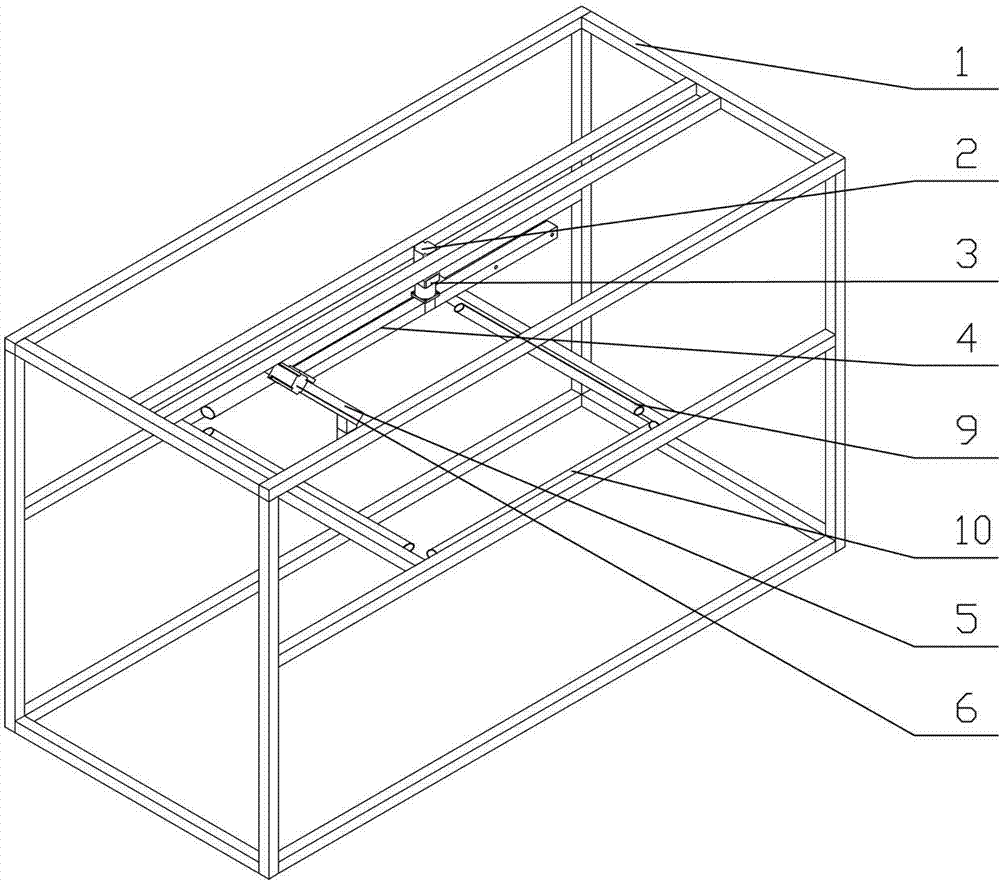

[0016] Such as Figure 1 to Figure 3 As shown in the figure, a fully automatic code reading machine for tires has a servo motor 2 movably connected to the fixed frame body 1, the output shaft of the servo motor 2 is vertically downward, and is connected to the middle part of the mechanical arm 4 arranged horizontally through the reducer 3 , the lifting track 5 at one end of the mechanical arm 4, the axis of the lifting track 5 is at an angle of 30° to 90° with the bottom surface of the mechanical arm 4, the upper end of the lifting track 5 is driven by a stepping motor 6, and the lower end of the lifting track 5 is set There is a vertically placed industrial code-reading camera 7 for plane scanning of the identification code pasted on the tire surface; wherein the servo motor 2, the stepper motor 6 and the camera 7 are respectively connected to an external PLC controller.

[0017] A light source fixing frame 9 is arranged below the industrial code-reading camera 7, and a light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com