Apparatus for the manufacture of bakery products

A baking and product technology, applied in the field of crisp wafers or soft wafers, can solve the problems of unusable baked products, damage to mechanical parts, and waste products in the oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

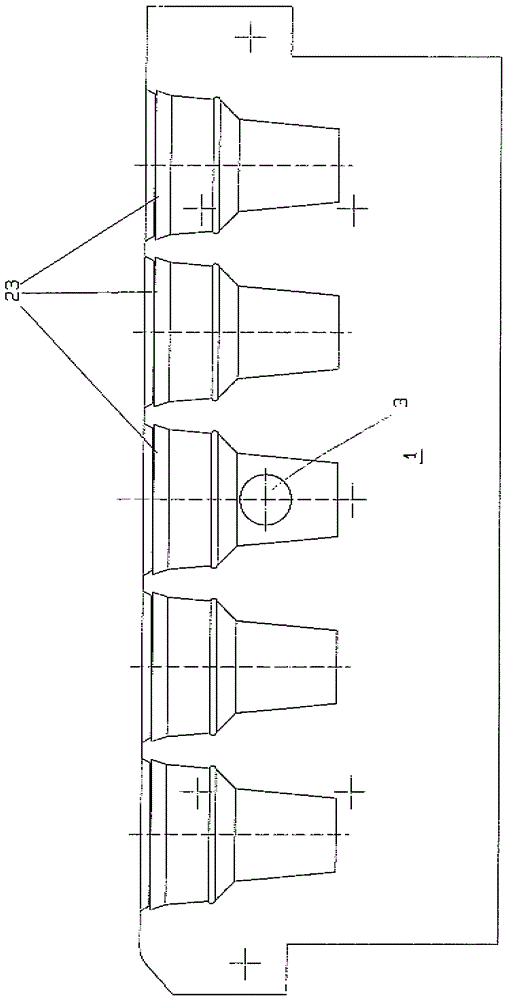

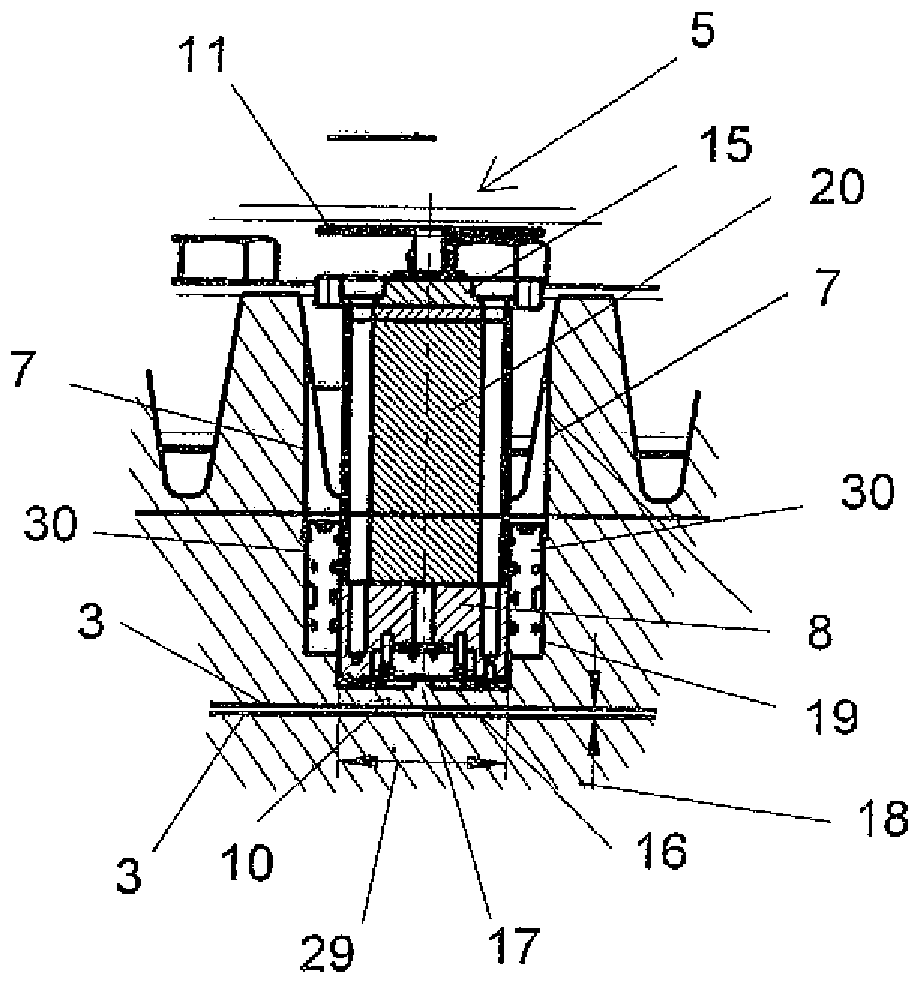

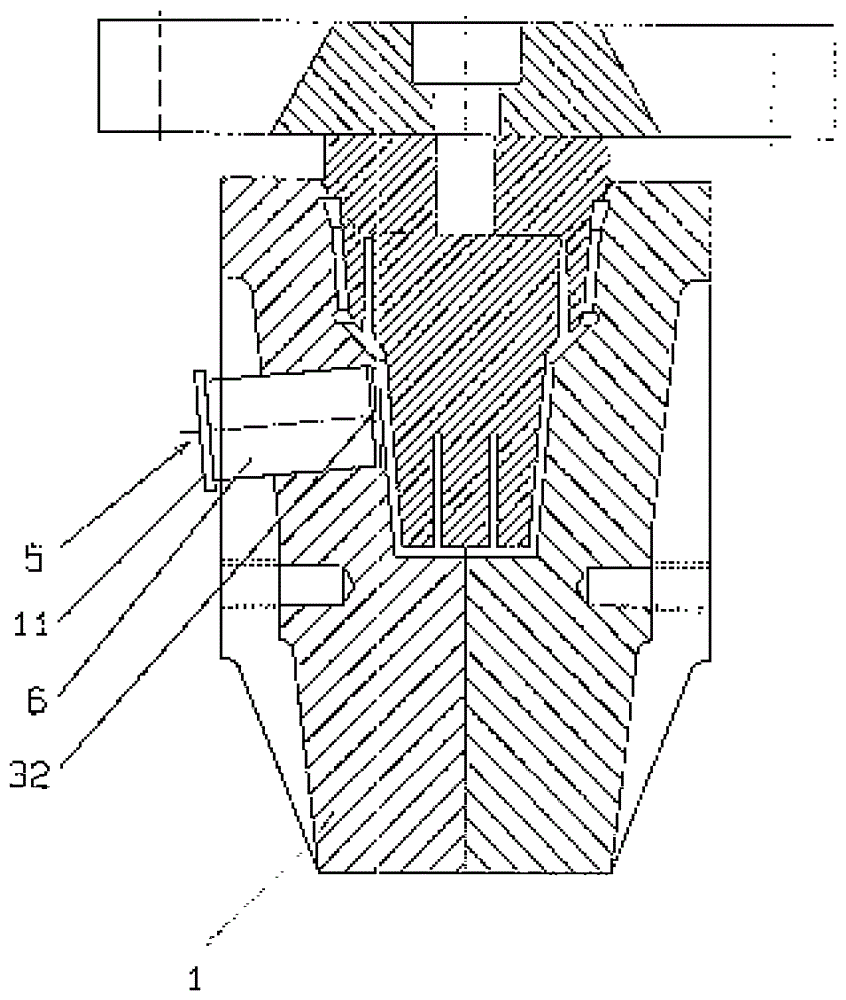

[0027] Figures 1 to 3 A baking tray according to the invention is shown, the basic construction of which corresponds to the prior art. The illustrated embodiment shows an upper baking tray 1 and a lower baking tray 2 , wherein this is a self-supporting baking tray which does not require support frames. In the closed state shown, the two baking trays are close together on the baking surface to such an extent that only the required gap 4 for the dough to be baked remains between the baking surfaces. The baking surface can be provided with grooves in a known manner, as is known from flat wafers or soft wafers. Groove in Figures 1 to 3 not shown in

[0028] as in figure 2 As shown in cross-section in , the upper baking tray has a sensor arrangement 5 in the form of a separate sensor 6 . The sensor 6 is arranged in the baking tray in the sensor receiving opening 7 , wherein in this embodiment the sensor extends with its sensor head 8 as far as the adjacent baking surface 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com