Baking equipment for printing

A technology for baking equipment and casings, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problem of drying, the other part has not changed, the printing is not uniformly baked, and the heat dissipation function of the body is not good. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

[0035] The structure of the present invention will be described in detail below with reference to the accompanying drawings.

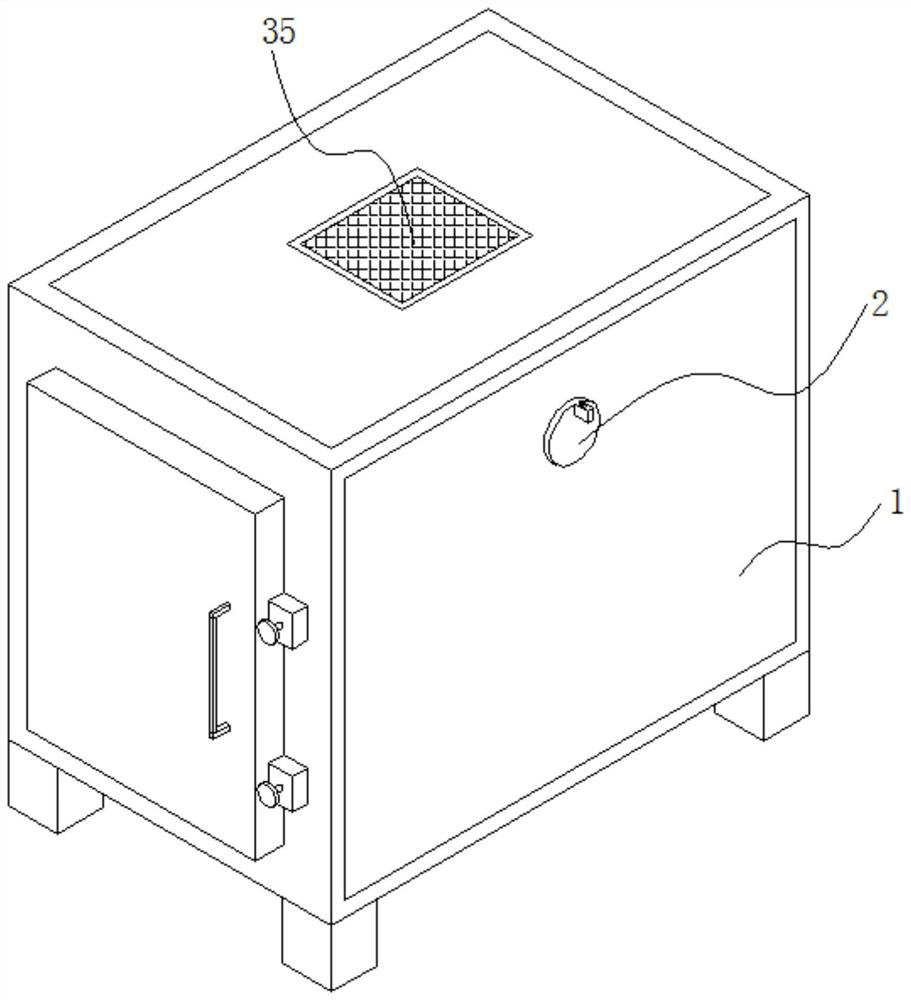

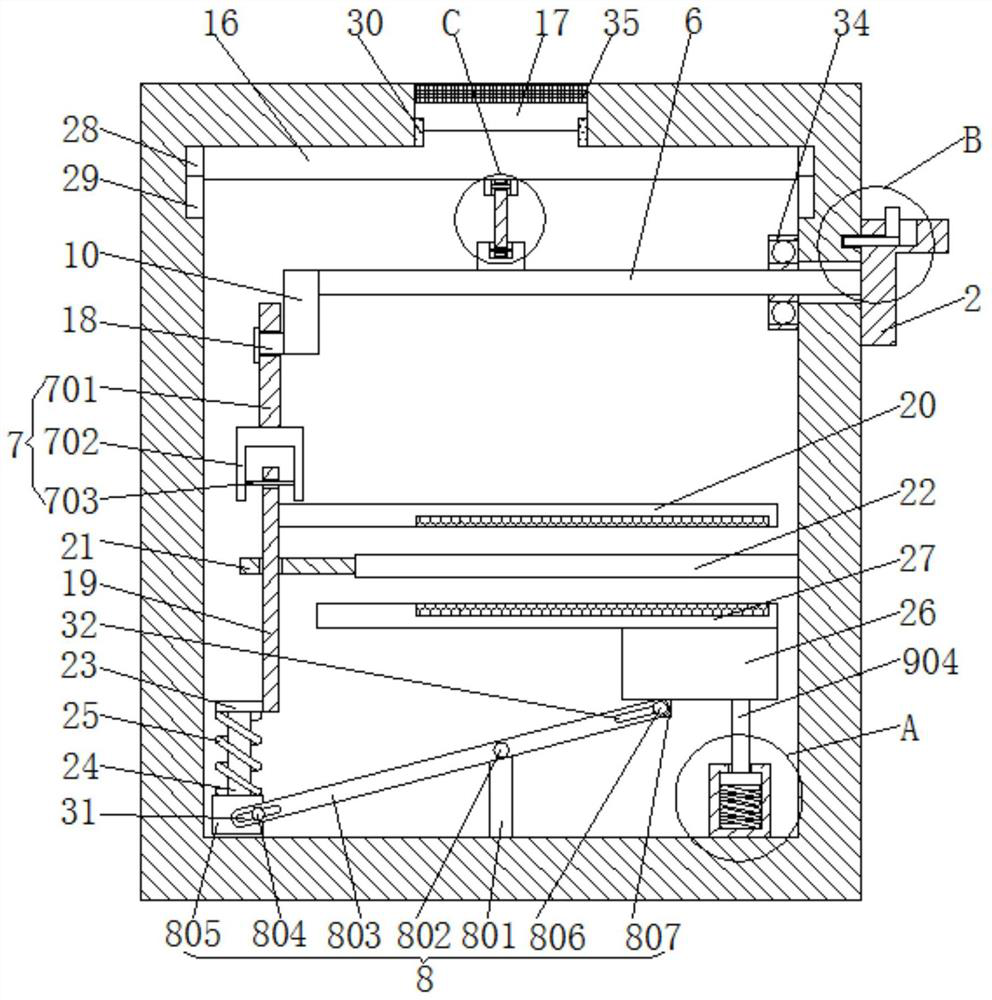

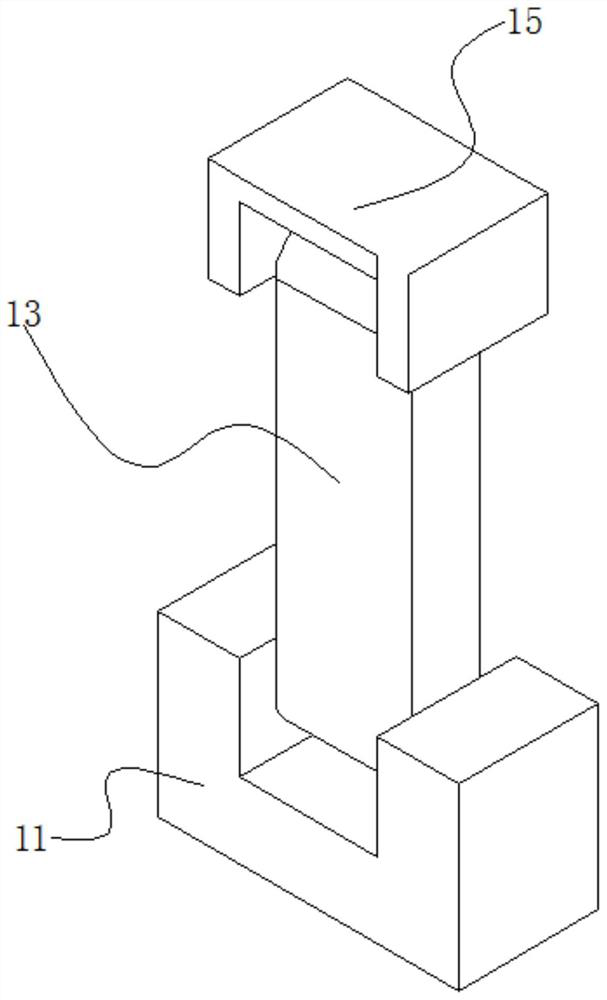

[0036] like Figure 1 to Figure 7As shown in the figure, a printing baking device provided by an embodiment of the present invention includes a casing 1, a control panel 2 is arranged on the right side of the casing 1, and an L-shaped groove 3 is opened inside the control panel 2. The L-shaped groove 3 An L-shaped block 4 is movably connected to the inside of the L-shaped block 4. The left side of the L-shaped block 4 runs through to the left side of the control panel 2. The left side of the transmission shaft 6 is fixedly connected with the transmission shaft 6, the left side of the transmission shaft 6 penetrates into the interior of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com