Method of controlling adjusting hole

A control method and a technology of adjusting holes, which are applied in flow control, flow control of auxiliary non-electric power, control/regulation systems, etc., and can solve problems such as wear, control characteristic changes, and inability to achieve control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Whether the control device for the regulating hole of the present invention can regulate the fluid flow has been tested, and an embodiment of the experiment (experimental example) will be described below. However, the present invention is not limited by this Example.

[0143]

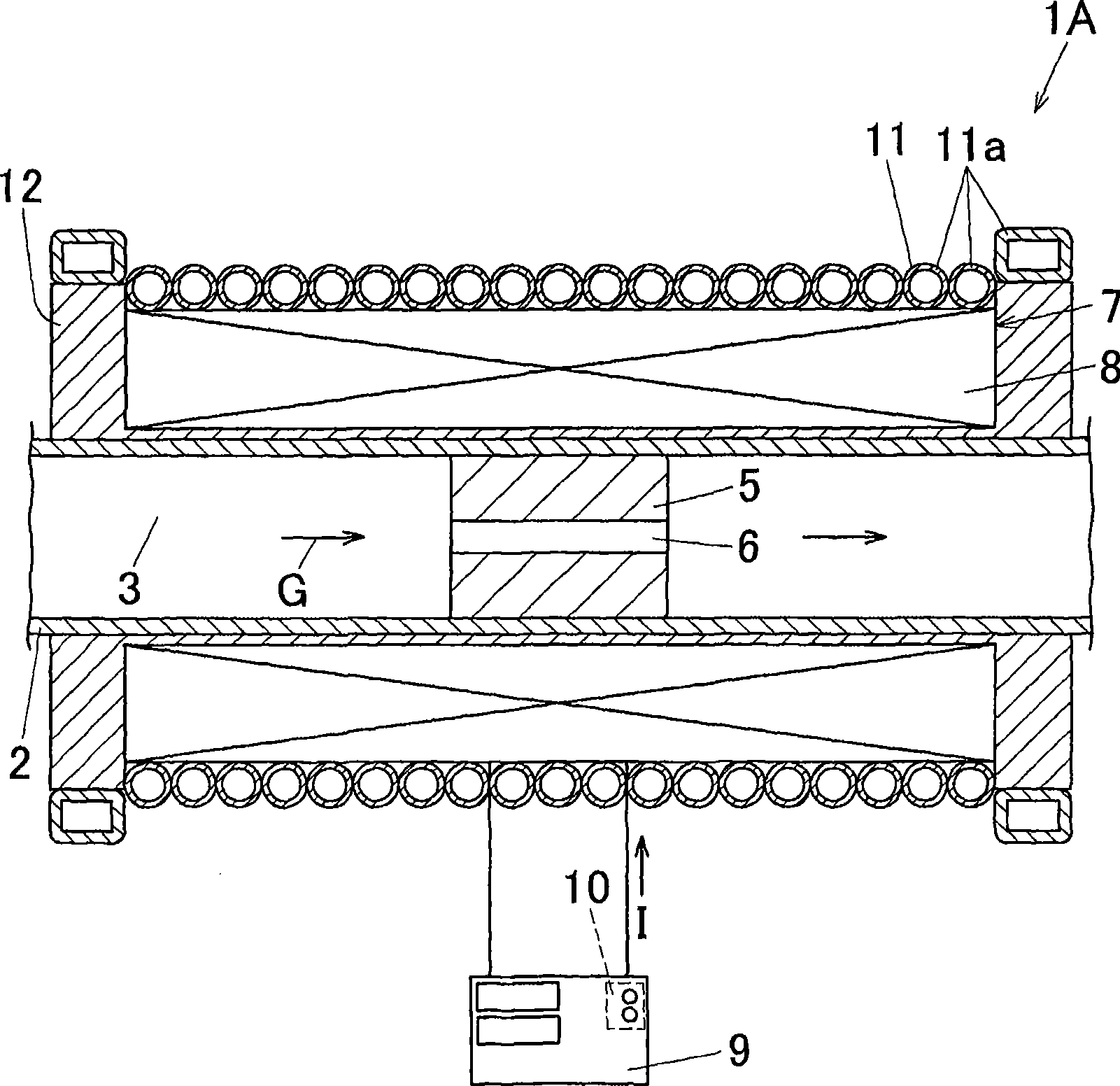

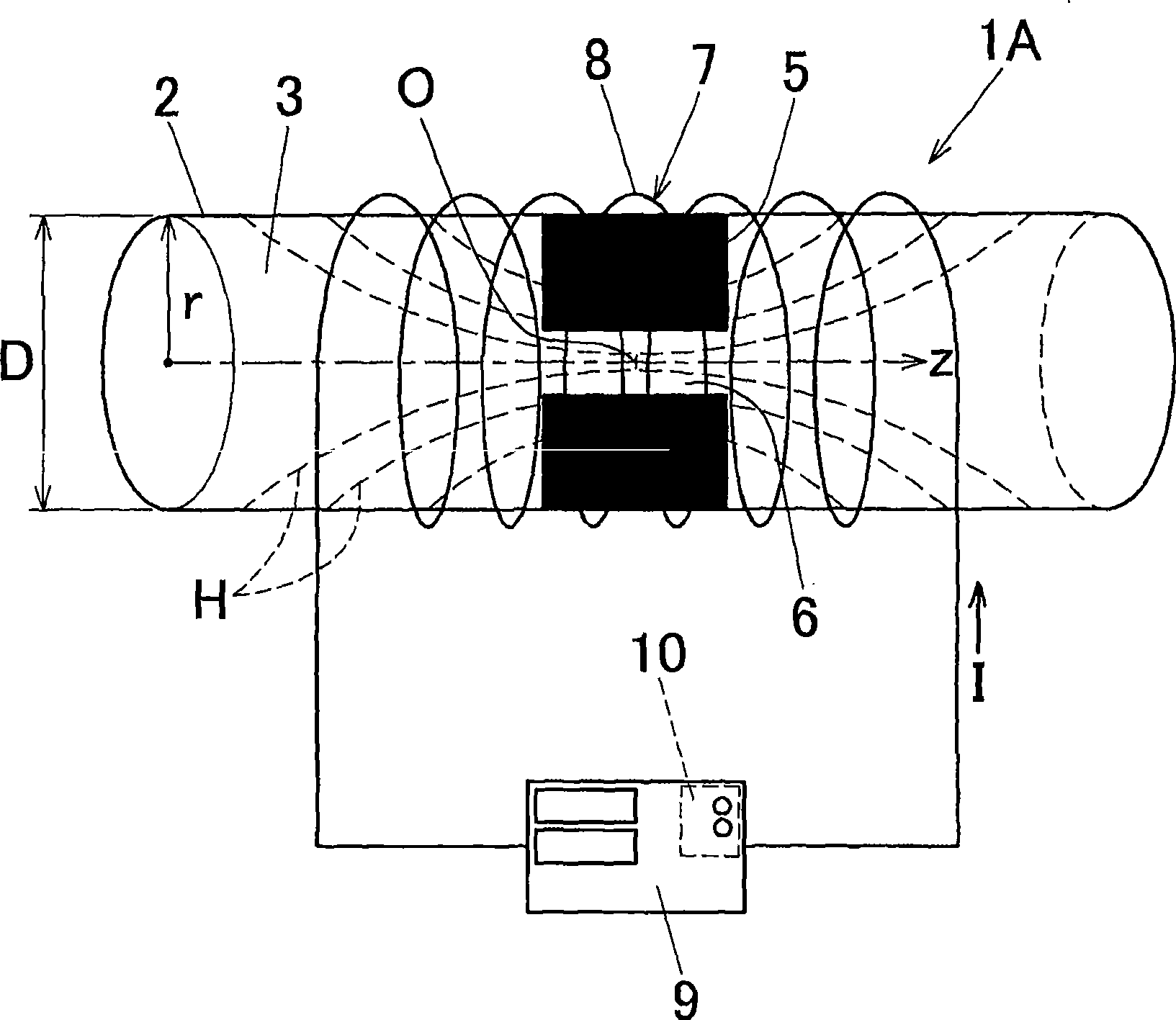

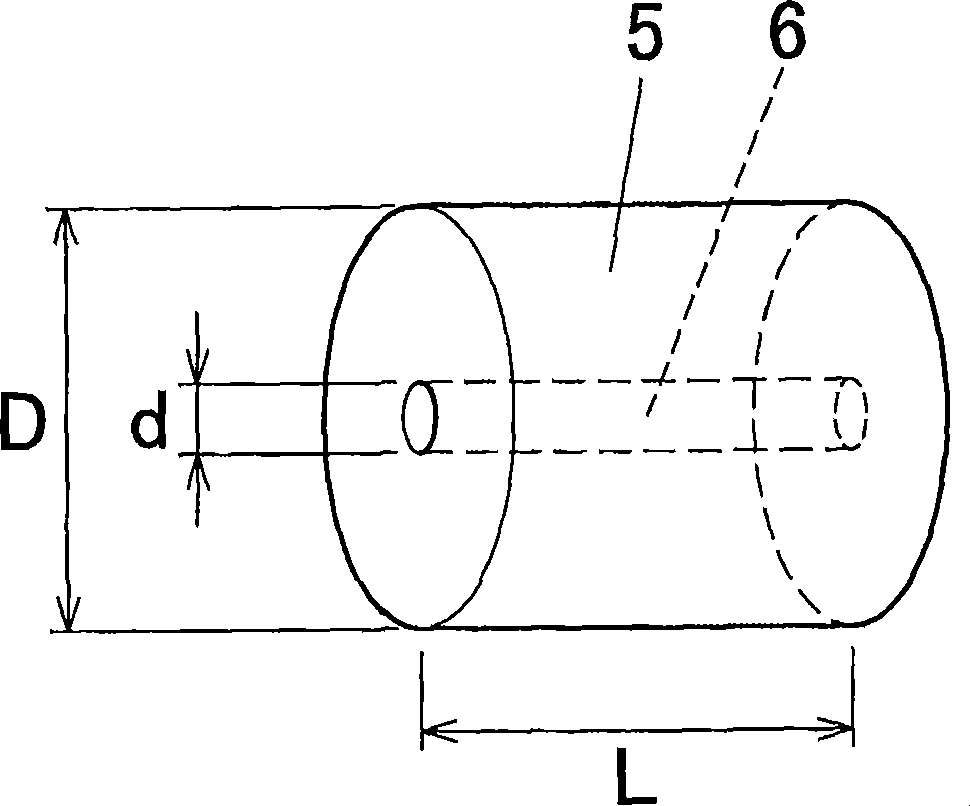

[0144] Fig. 7 is a schematic diagram of a control device (1C) for an adjustment hole used in this example (experimental example). In the control device (1C), the diameter D of the pipeline (3) of the pipe body (2) (see figure 2 ) is 12mm. The tube body (2) is made of transparent acrylic, and its wall thickness is 1-2mm. The length L of the partition wall (5) is 12 mm. Such as image 3 As shown, in the central portion of the partition (5), an adjustment hole (6) is provided straight through along the axial direction of the pipeline (3), and the diameter d of the adjustment hole (6) is 1.0mm.

[0145] In this control device (1C), (51) is an electric motor, (52) is a speed controller, (53) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com