Adjustment drive for a vehicle, in particular tailgate drive

A technology for driving devices and trunk lids, which is applied to transmission devices, gear transmissions, vehicle components, etc., can solve problems such as difficult assembly of trunk lid driving devices, and achieve the effect of reducing tolerance chains and tolerance chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

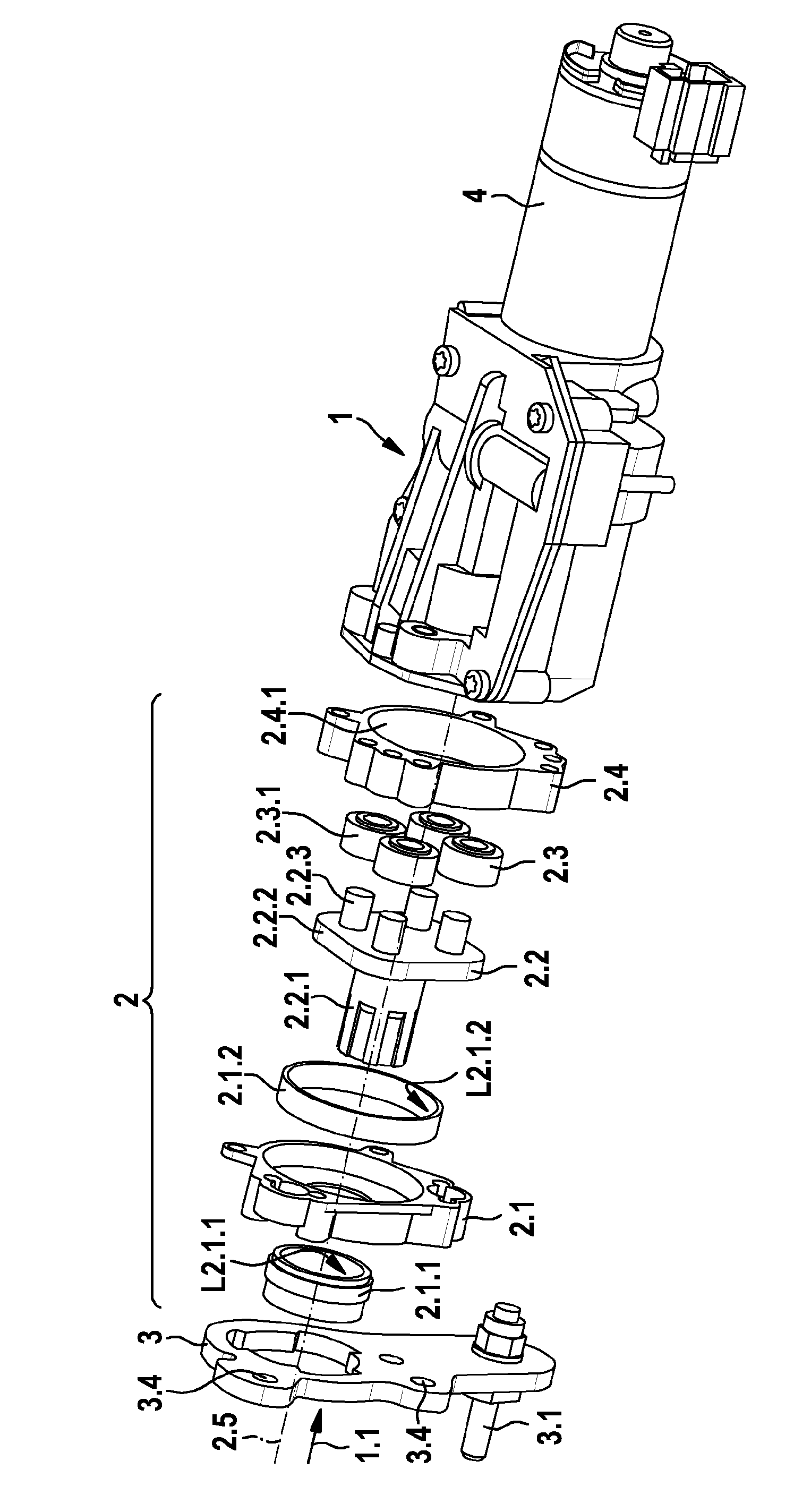

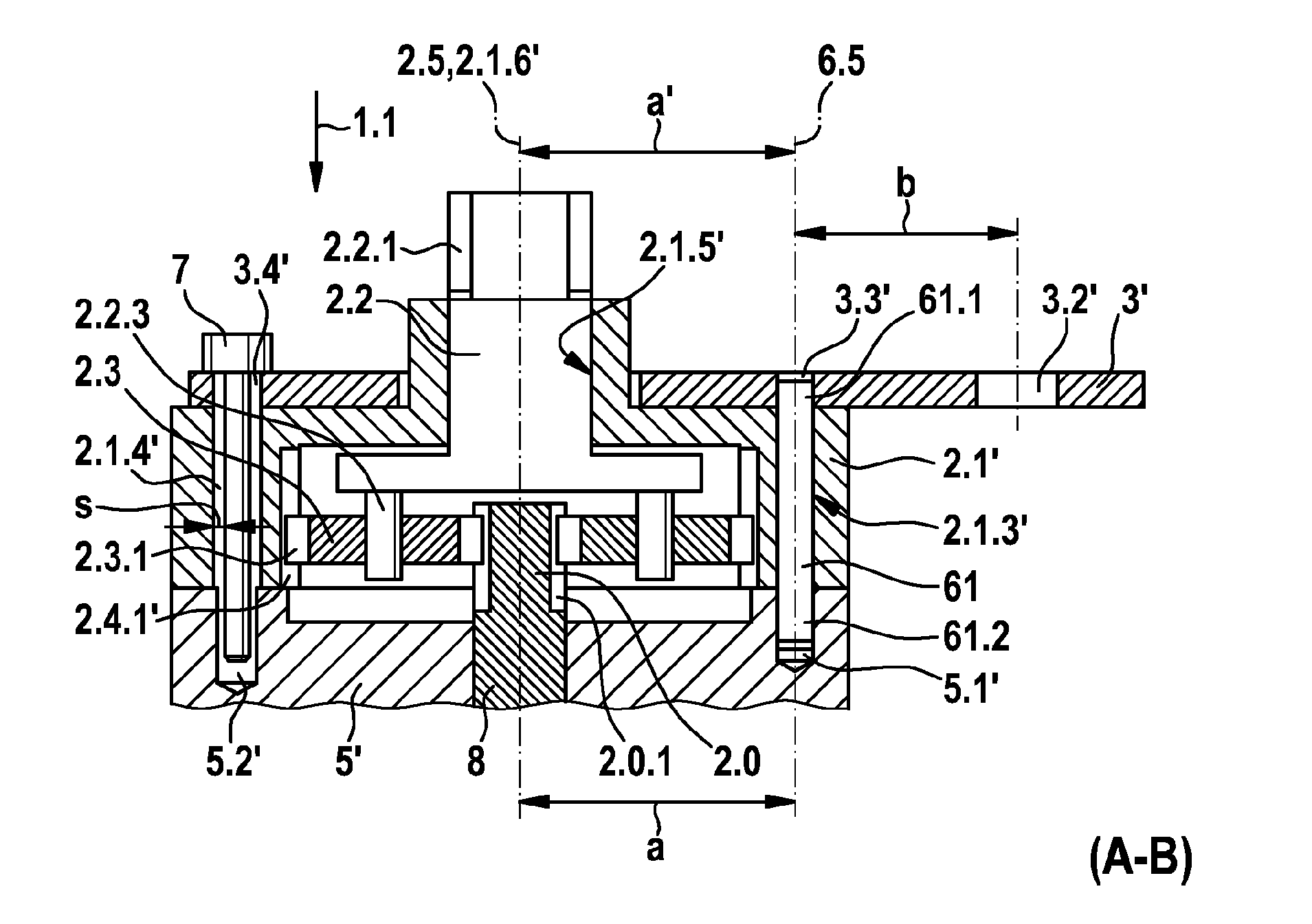

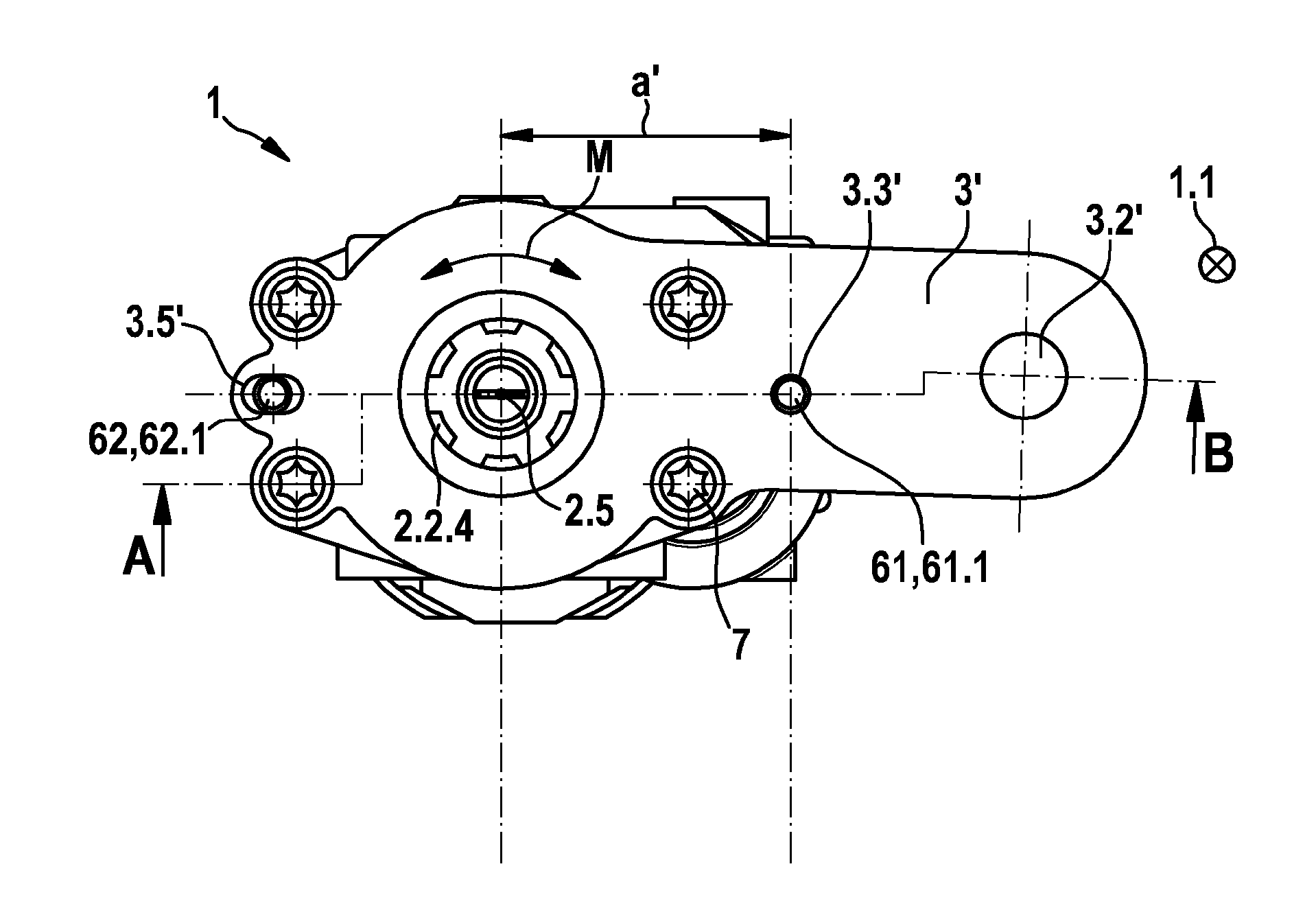

[0026] FIG. 1 schematically shows an adjusting drive 1 for a component, here a boot lid drive of a vehicle, according to the prior art. The terms adjusting drive and tailgate drive are used synonymously below. The tailgate drive 1 has a plurality of gear stages (not shown), the last, output-side gear 2 being a planetary gear. The planetary gear 2 is shown exploded in FIG. 1 . In the following text, the terms output-side transmission 2 and planetary gear are used synonymously.

[0027] An electric motor is provided as drive motor 4 for driving the tailgate drive 1 . The terms drive motor 4 and electric motor are used synonymously below. Furthermore, FIG. 1 shows a fastening component 3 , which is designed here as a fastening plate and which forms an interface for adjusting the luggage compartment lid (not shown). For this reason the bolt 3.1 is releasably arranged in the fixing hole 3.2 in the fixing member 3 (see figure 2 )middle. The concepts of fixing member 3 and fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com