Shearing machine receiving device

A material receiving device and shearing machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unfavorable use of forklifts and other processes, and short intervals of forklift fork materials, and achieve simple structure and labor saving. The effect of high degree of automation and stable material storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

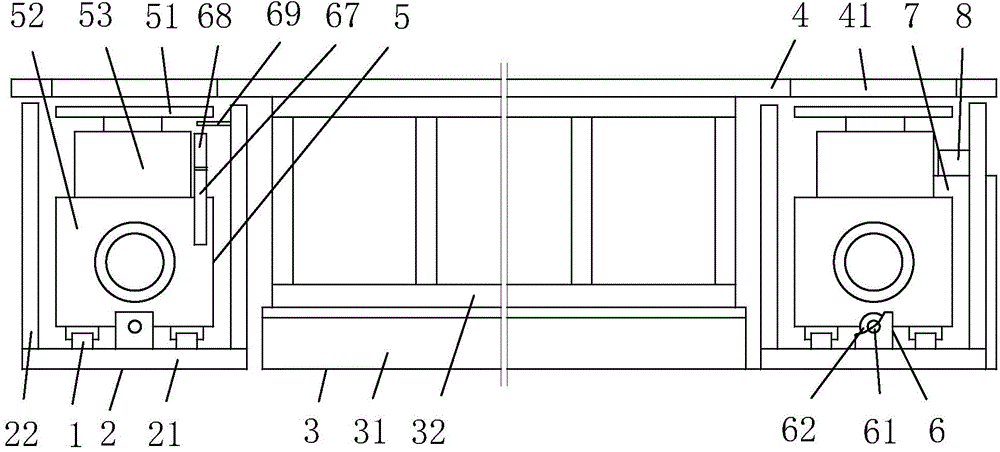

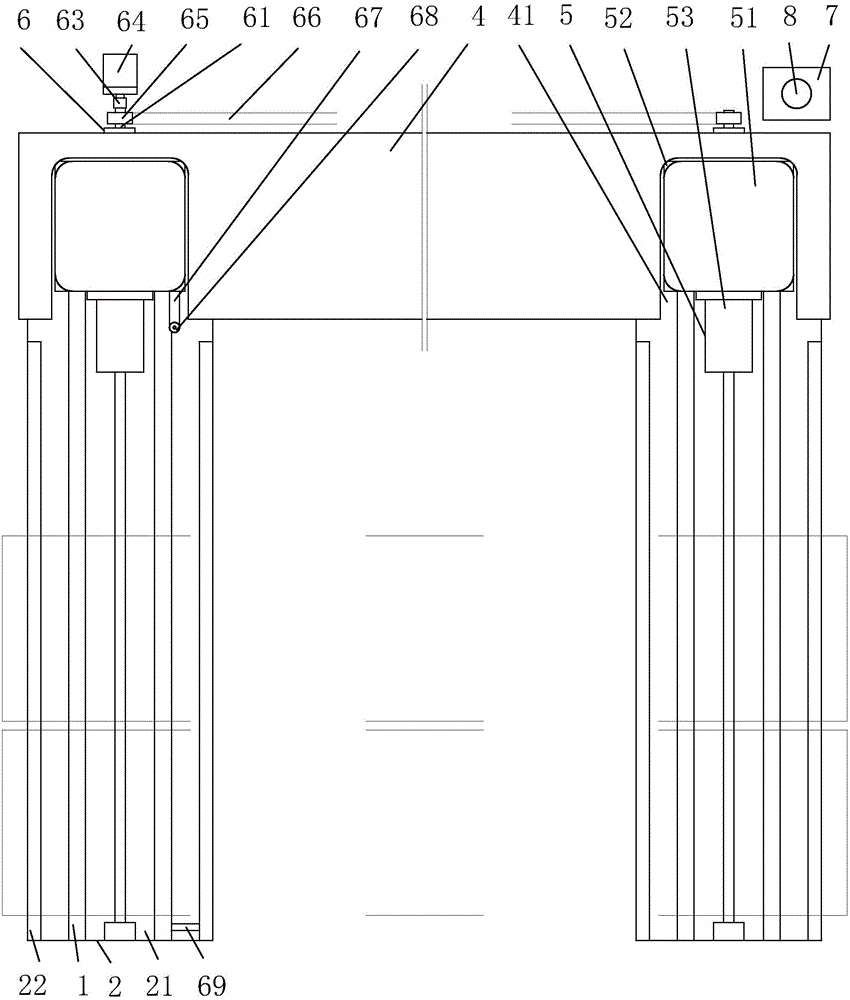

[0017] as attached figure 1 , attached figure 2 Shown: a material receiving device for a shearing machine, including two material receiving racks 2 with a bottom plate 21 and at least one side plate 22, a material receiving rack 3 located between the rear ends of the two material racks 2, and a material receiving device The material receiving plate 4 fixedly connected to the upper end of the frame 3, the lifting device 5 provided with the plate backing plate 51 at the two upper ends and the driving device 6 for driving the lifting device 5 to move back and forth along the shelf 2; each lifting device 5 passes through At least one slide rail 1 is connected with the bottom plate 21 of a material rack 2; each end of the opposite ends of the material receiving plate 4 protrudes from the outer side of the material rack 2; The side edge is penetrated and the size is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com