Blast furnace shell air opening flange hole forming method

A tuyere flange and furnace shell tuyere technology is applied in the field of blast furnace shell construction and can solve problems such as poor opening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention adopts following steps construction:

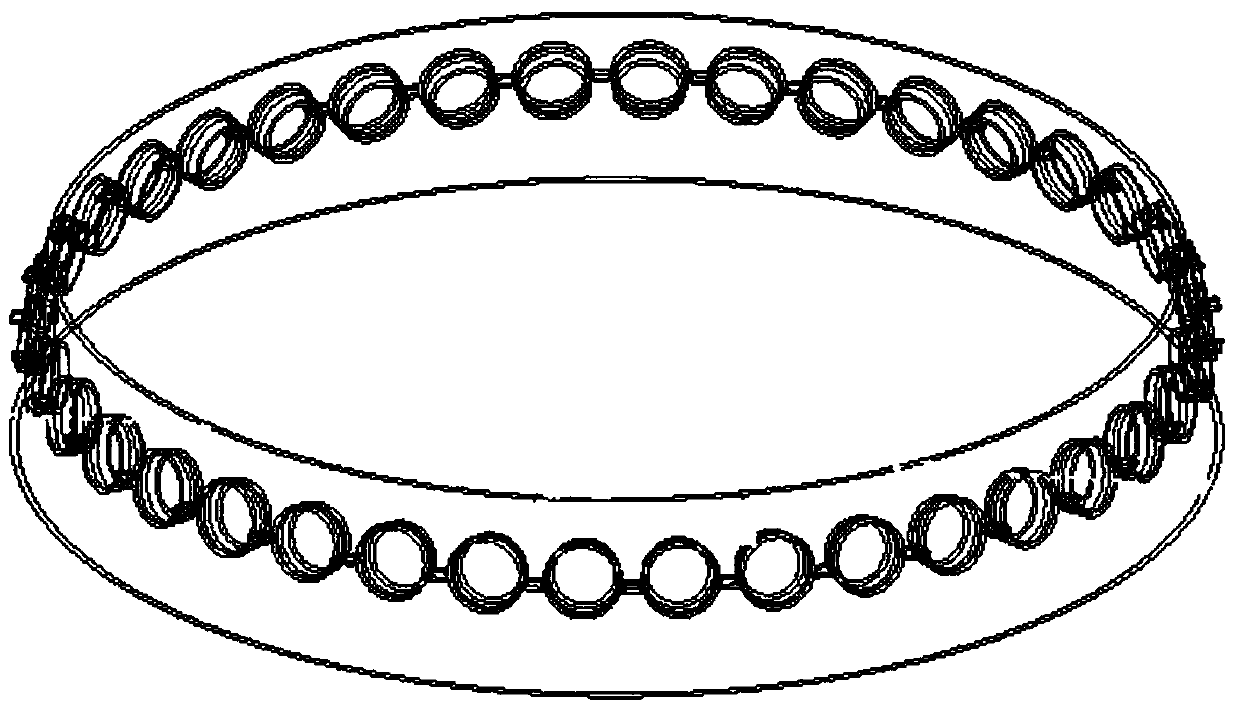

[0024] 1. The center line of the blast furnace shell tuyere flange hole is not perpendicular to the furnace shell plate surface, and is horizontal to the ground ( figure 1 ).

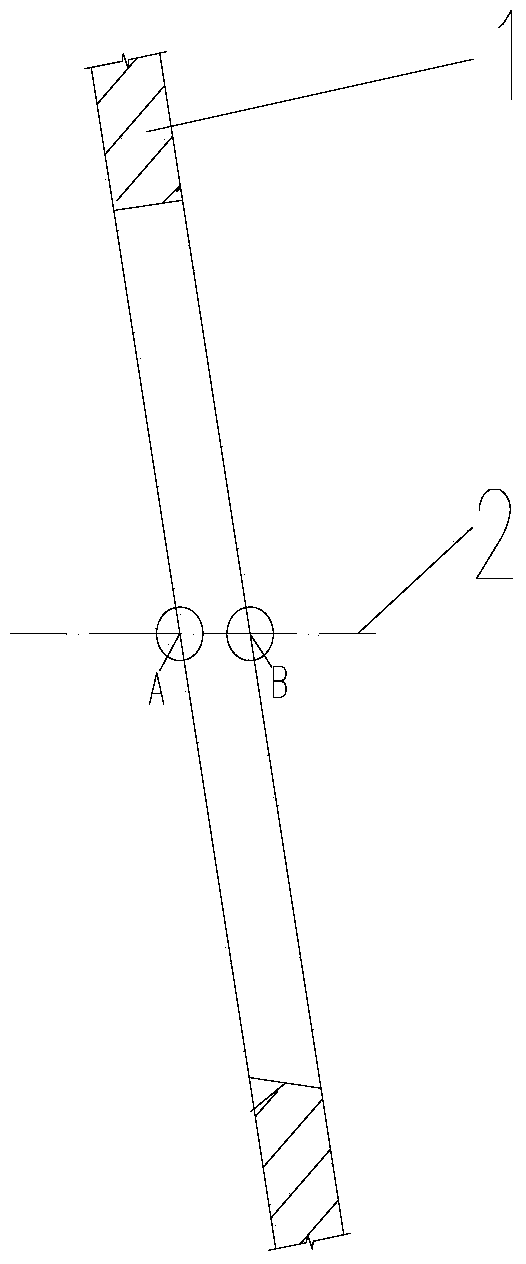

[0025] 2. The flange holes of the tuyere are opened after the steel plate is rolled, and when the flanges of the tuyere are pre-assembled, the center of each tuyere flange is marked with a total station. First, punch the inner center point A on the inner wall of the furnace shell plate 1, and then lead the point A to the outer point B of the furnace shell plate 1. The AB line is the center line of the tuyere flange hole 2 of the tuyere flange opening ( figure 2 ).

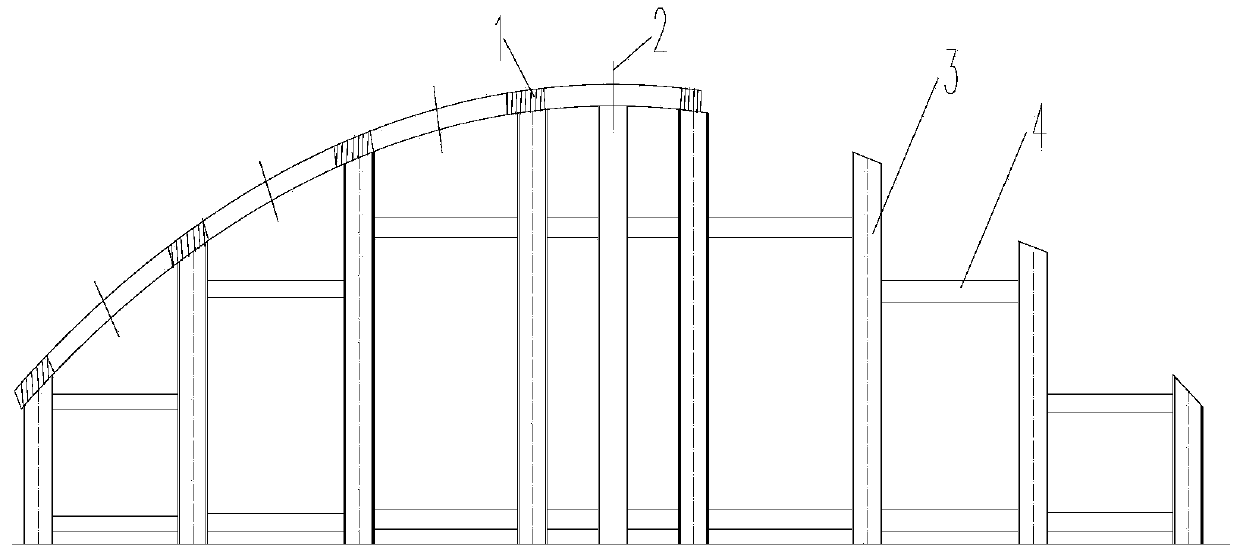

[0026] 3. Design of perforated mold

[0027] The mold is designed according to the angle of the furnace shell plate 2 to ensure that the center line 2 of the flange hole of the tuyere is perpendicular to the ground ( image 3 , Figure 4 ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com