Method and system for achieving functions of numerical control machine tool magazine tool based on macroprogram

A technology of numerical control machine tools and macro programs, applied in the field of industrial manufacturing, can solve problems such as inflexibility of the system, unfavorable program maintenance and debugging, etc., and achieve the effect of enhancing flexibility and intuitive and convenient maintenance and debugging methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

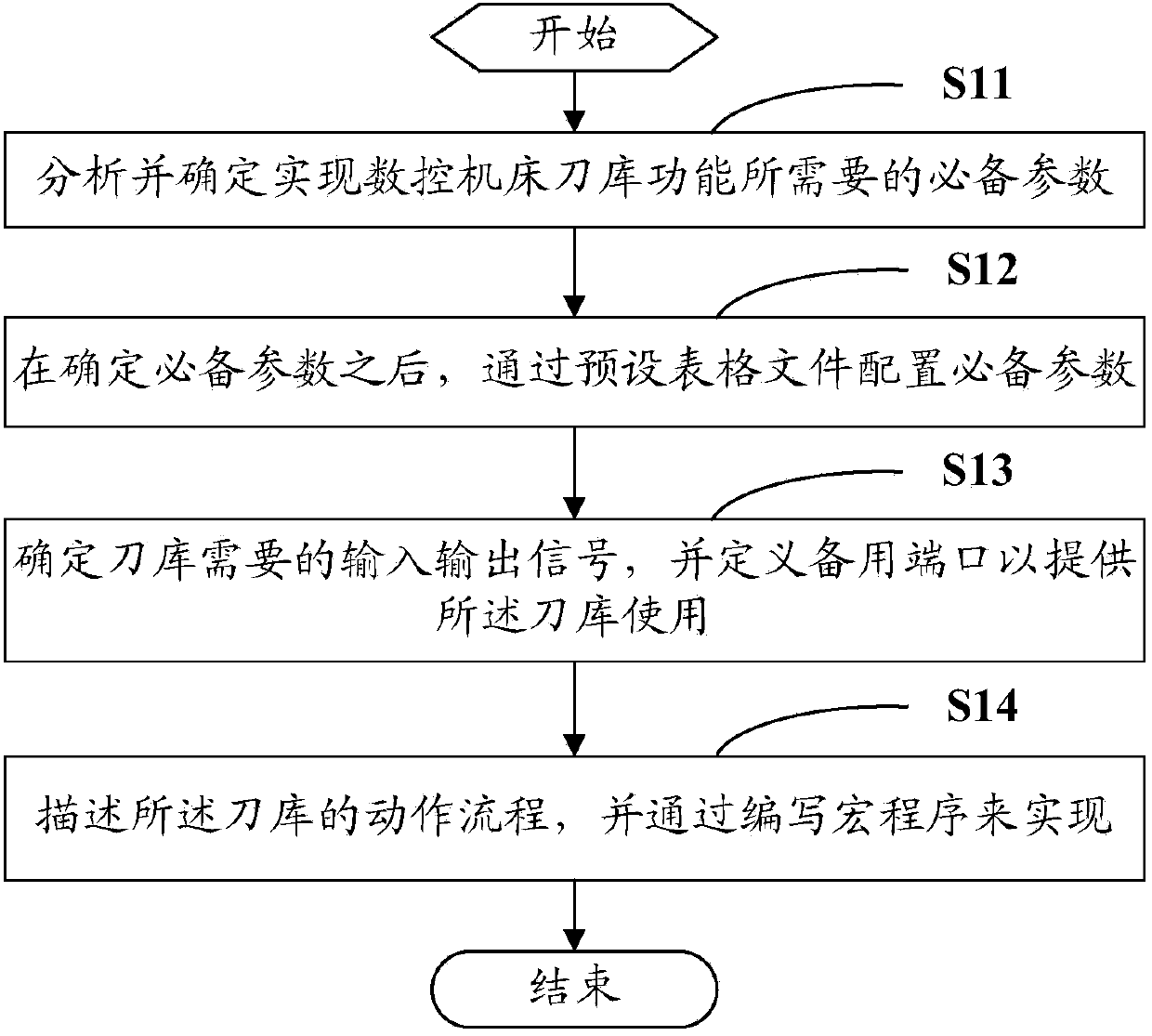

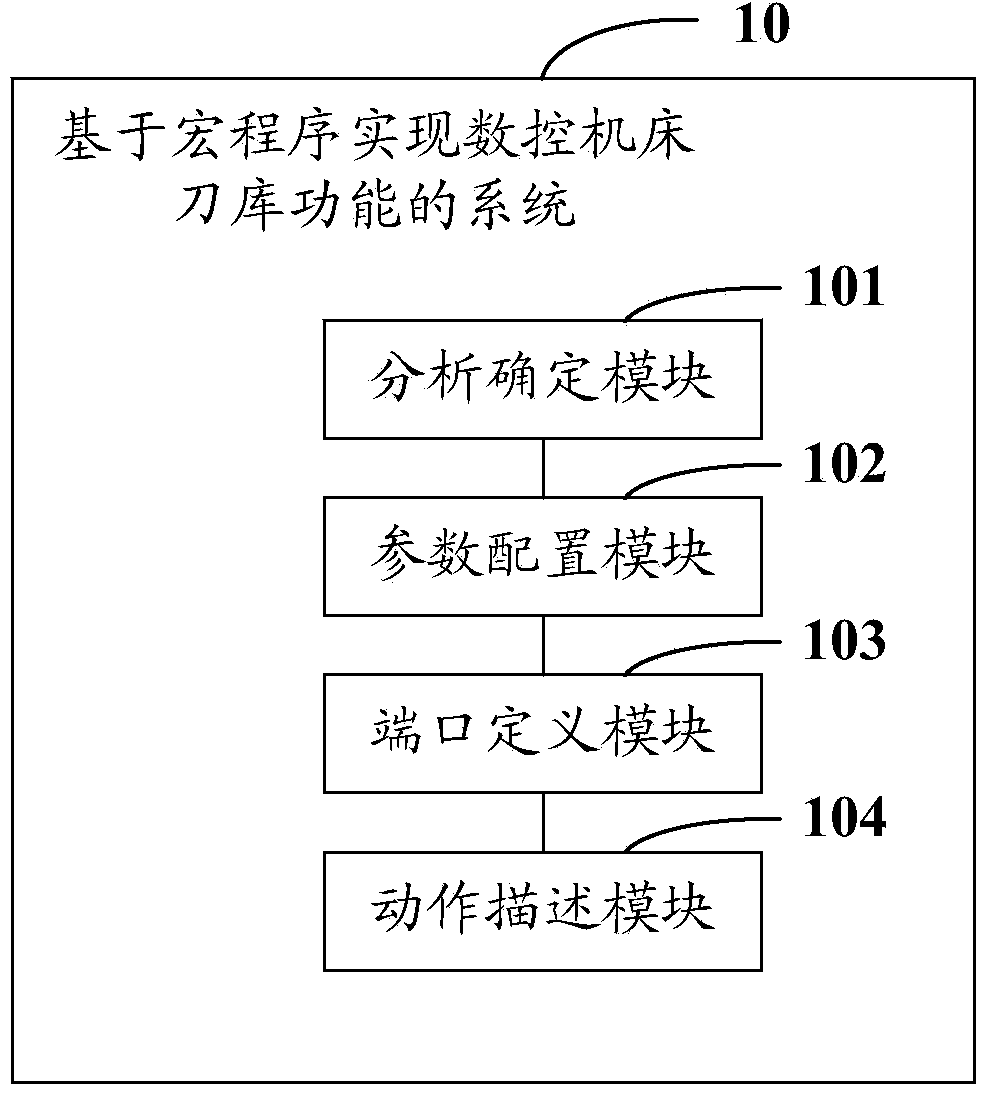

[0039] The specific embodiment of the present invention provides a method for realizing the tool magazine function of a CNC machine tool based on a macro program, which mainly includes the following steps:

[0040] S11. Analyzing and determining the necessary parameters required to realize the tool magazine function of the CNC machine tool;

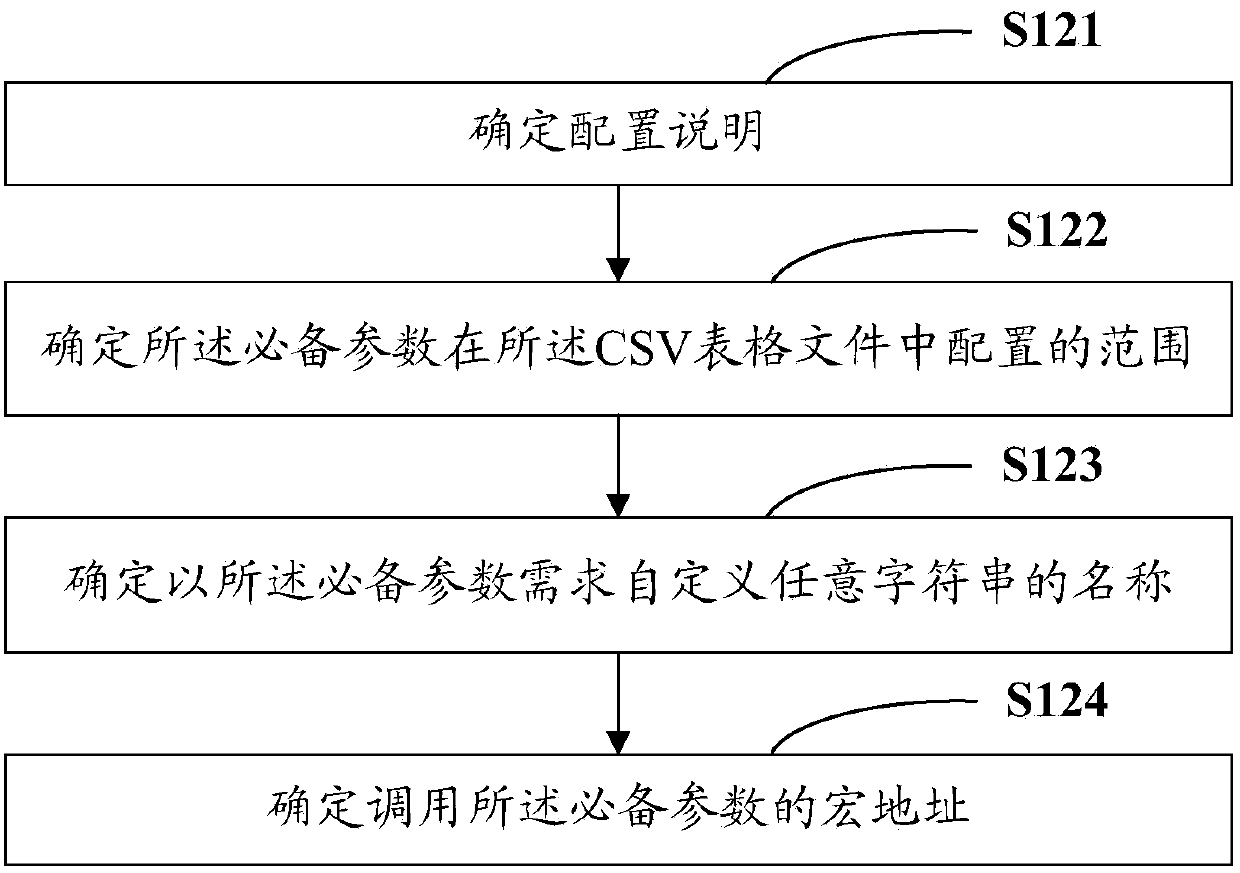

[0041] S12. After determining the necessary parameters, configure the necessary parameters through a preset table file;

[0042] S13. Determine the input and output signals required by the tool magazine, and define a spare port for use by the tool magazine; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap