A prepreg cutting device and cutting method

A prepreg cutting technology, applied in the direction of transportation and packaging, metal processing, sending objects, etc., can solve the problems of inability to achieve cutting, insufficient precision, difficult to control the heating process, etc., to prevent local burning or insufficient softening, avoid The effect of performance degradation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

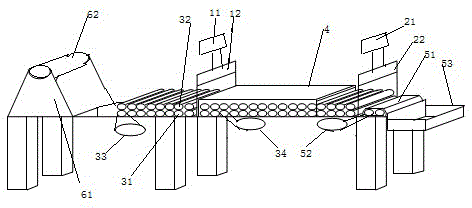

[0033] This embodiment provides a prepreg cutting device for cutting ceramic materials, such as figure 1 Shown includes a heating unit for heating the prepreg, a feeding unit that is arranged in front of the heating unit and can feed the strip-shaped prepreg into the heating unit, a front cutting part that is cross-mounted on the feeding unit and the heating unit, and a cross-frame on the heating unit. The rear cutting part at the end; the feeding unit is provided with a transmission mechanism A, and the heating unit is provided with a transmission mechanism B; it also includes a device for controlling the operation of the feeding unit, the heating unit, the front cutting part and the rear cutting part control unit.

[0034] The front cutting part includes a front sensing mechanism arranged on the transmission mechanism A that can sense the strip-shaped prepreg, a front cutting cylinder 11 arranged above the transmission mechanism A, and a front cutting cylinder 11 arranged on...

Embodiment 2

[0045] This embodiment provides a method for cutting a ceramic prepreg using the solidified sheet cutting device of Embodiment 1.

[0046] Including the following procedures:

[0047] Wrap the strip-shaped prepreg on the fixed shaft 62, and put its end into the gap between the driven conveying roller group and the driving conveying roller group of the feeding unit; preset the length of the prepreg to the control unit and the temperature sufficient to soften the prepreg. The softening temperature of different prepreg materials is different. For example, the softening temperature of ceramic prepreg is 30-40°C, and the softening time is 20 seconds; is 35°C.

[0048] Use the control unit to control the motor 33 of the transmission mechanism A to drive the active transmission roller group to drive the strip-shaped prepreg to advance in the feeding mechanism;

[0049] When the strip-shaped prepreg moves to the bottom of the front sensing mechanism, the front sensing mechanism trig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com