Seismic energy dissipation structure of multi-column bridge piers

A bridge pier and earthquake technology, applied in the field of multi-column bridge pier seismic energy dissipation structures, can solve the problems of high cost of lead-core bearings, difficult repair of connecting beams, and difficulty in immediate repair, etc., and achieves good shock absorption effect, wide application range, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and embodiments.

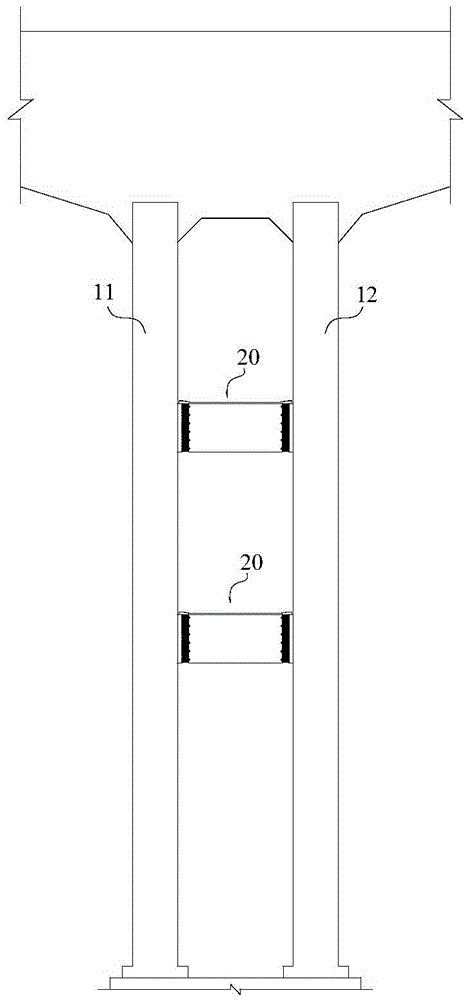

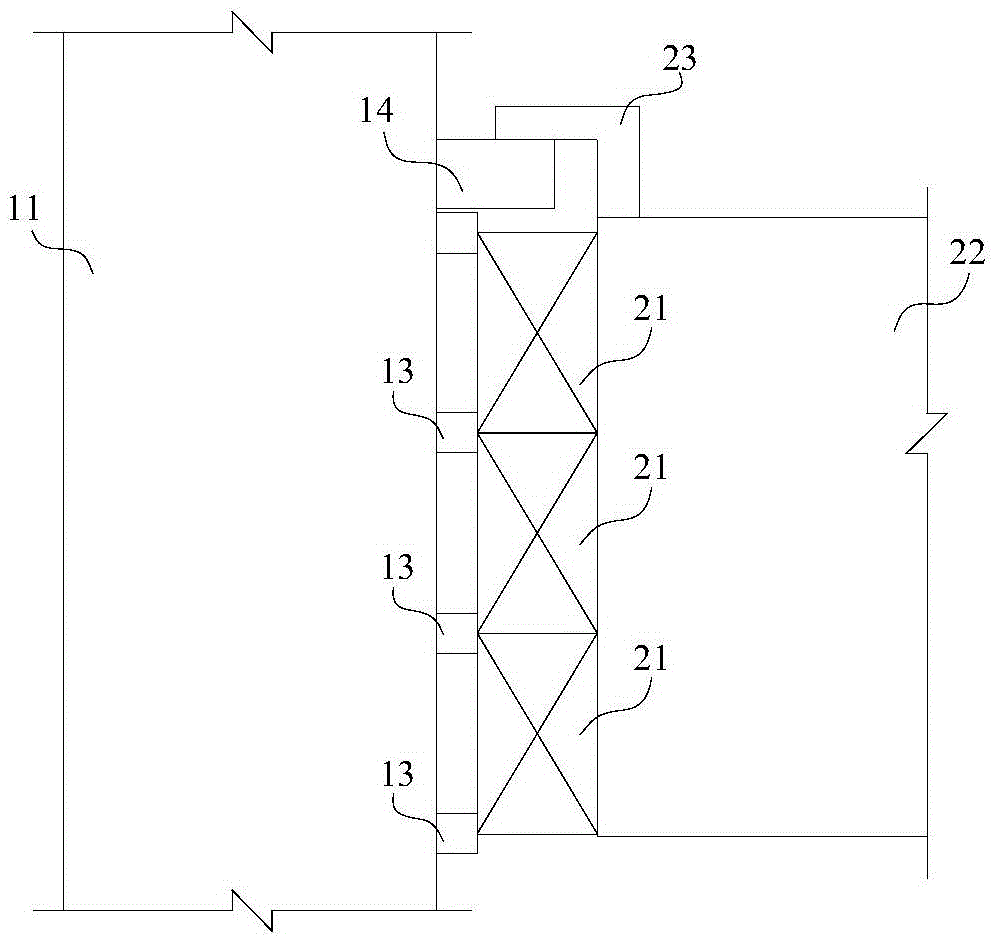

[0015] Reference figure 1 The multi-column pier seismic energy dissipation structure of the present invention includes adjacent left pier columns 11 and right pier columns 12. One or a plurality of energy dissipating cross beams 20 are arranged between the left pier column 11 and the right pier column 12 at intervals along the longitudinal direction. The energy dissipating cross beam 20 includes a steel structure cross beam 22 and is fixedly arranged in its longitudinal direction. The mild steel energy dissipation components at both ends are connected with the left pier column 11 and the right pier column 12.

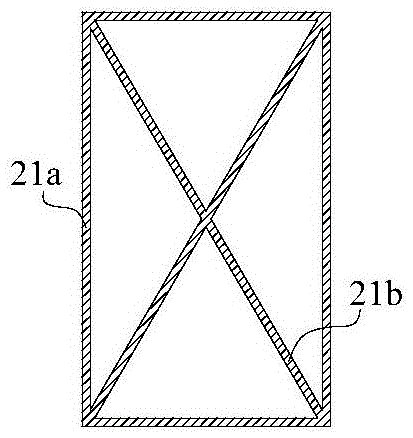

[0016] Reference image 3 with Figure 4 The mild steel energy dissipating component is composed of mild steel energy dissipating unit groups arranged on the end surface of the steel structure cross beam 22 at intervals, and each mild steel energy dissipating uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com