Method for passing through top-coal caving region of roadway

A technology for high-risk areas and roadways, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems affecting mine excavation succession, complicated processes, and high labor intensity of workers, and achieves small underground auxiliary transportation volume, safety and reliability High, wide-ranging practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing:

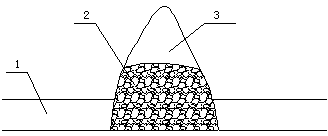

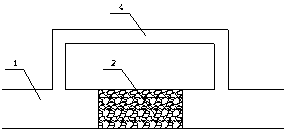

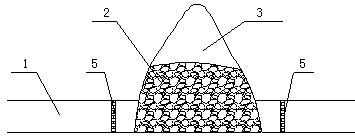

[0024] Such as Figure 1 to Figure 8 Shown, the method for passing through the roadway high risk area of the present invention may further comprise the steps:

[0025] a. Determine the location of the high-risk area 3 in the roadway 1, and excavate a side passage 4 at the upper part of the high-risk area 3 except the head-on position of the roadway;

[0026] b. A grout-stop wall 5 is built at 0.5m to 1.5m on both sides of the collapsed edge of the high-risk area 3 that needs to be excavated, and the space in the grout-stop wall 5 is filled with consolidation materials, and the Grouting and cementing is carried out at the falling gangue in the middle and lower part of the high-risking area 3 to enhance the integrity of the falling gangue. The grout-stop wall 5 is a two-four airtight wall or a sealing structure composed of wooden boards, steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com