Laser optical axis adjusting mechanism

A technology for adjusting mechanism and optical axis, which is applied in control/adjustment system, measuring device, surveying and mapping and navigation, etc. It can solve problems such as difficult popularization and application, changing laser optical axis, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

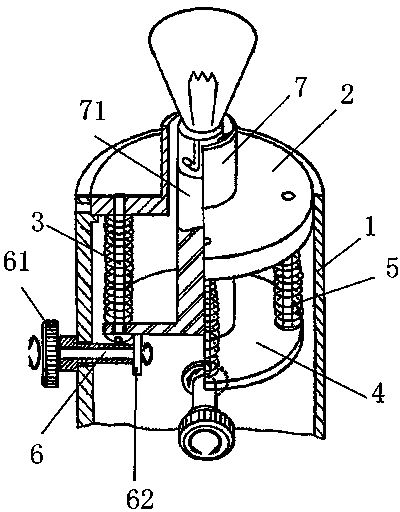

[0009] like figure 1 As shown, the laser optical axis adjustment mechanism of the present invention includes a hollow base 1, on which a support plate 2 is fixed by a limit card, and four support screws 3 are evenly distributed on the bottom circumference of the support plate 2, and the balance plate 4 is floated on the screw head, and a compression spring 5 is arranged between the balance plate 4 and the support plate 2. There are two knobs 61 with rotating rods 6 on the side wall of the base 1, the two rotating rods 6 are perpendicular to each other, and the end of the rotating rod 6 is fixed with a cam 62 in contact with the balance plate 4; The light source support 7 and the light source head 71 are placed in the light source support 7 , and one end of the light source head 71 is fixed on the balance plate 4 .

[0010] Since the cams 62 on the two rotating rods 6 are in contact with the balance plate 4, the cam 62 is rotated through the knob 61, and the balance plate 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com