Disc type brake automatic compensation gap braking clamp

An automatic compensation and disc brake technology, applied in the direction of brake type, brake actuator, axial brake, etc., can solve the problems of complex structure, inconvenient maintenance, etc., and achieve convenient clearance adjustment, timely and reliable braking, and convenient adjustment The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

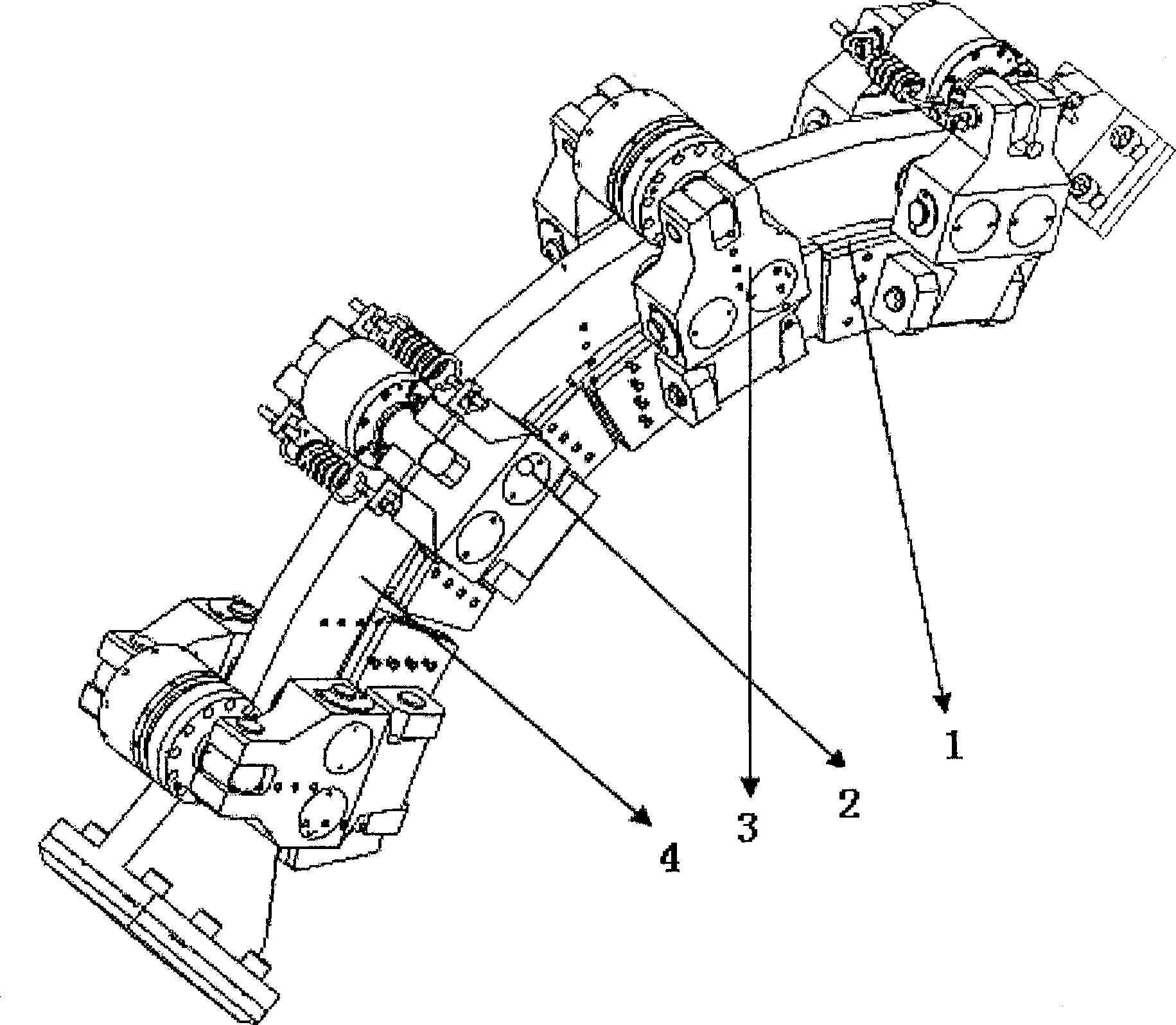

[0018] Embodiment 1: see figure 1 . Brake calipers for disc brakes that automatically compensate for gaps are mainly composed of a disc-shaped brake disc 1, 2 working pliers 2, 2 safety pliers 3 and an arc-shaped caliper frame 4. The brake disc 1 is fixed on the drum of the rig winch, and the caliper The frame 4 is fixed on the base of the winch by screws, and the two working tongs 2 and the two safety tongs 3 are respectively fixed on the tong frame 4 by the support shaft 11 .

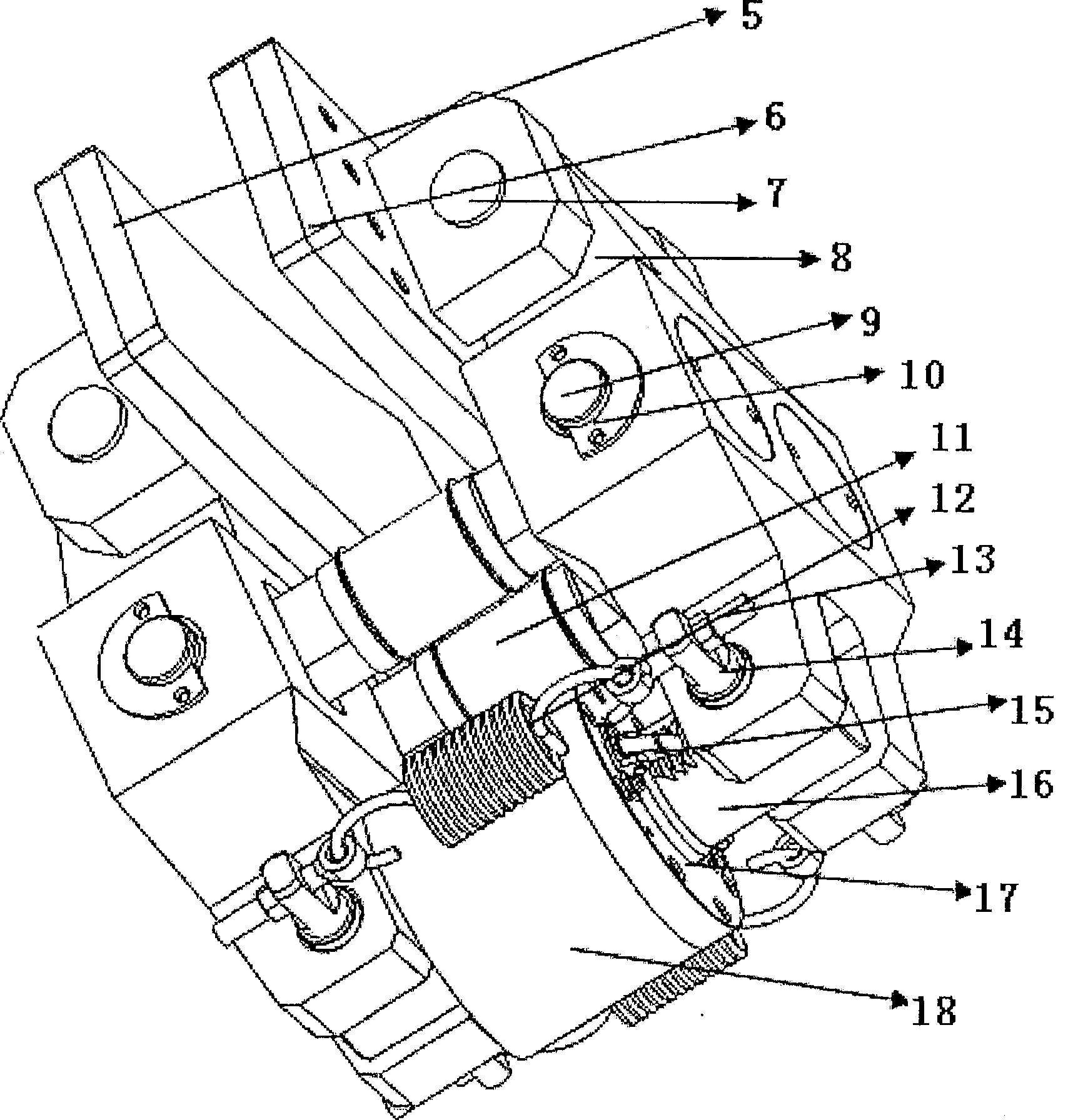

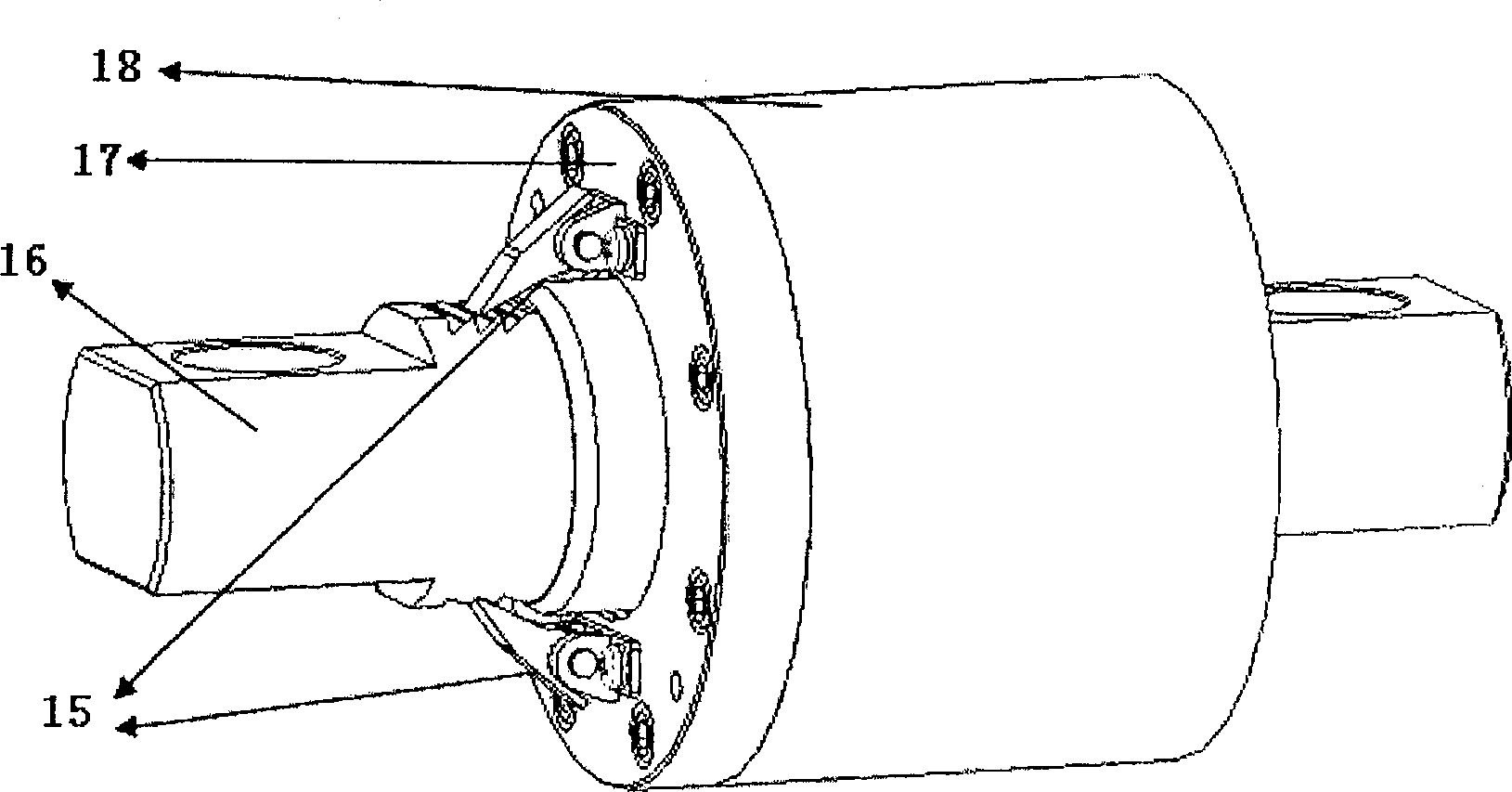

[0019] refer to figure 2 . The working tongs 2 are mainly composed of a working oil cylinder 18, a piston rod 16, a working lever 8, a pliers body 6, a coil spring 12, a support shaft 11 and a brake block 5, and countersunk screws are used to fix the brake blocks 5 to the two caliper bodies 6 respectively. inside. The two caliper bodies 6 are respectively connected to the ends of the two working levers 8 through pin shafts 7 . The middle of the support shaft 11 is cylindrical, and the middle cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com